Looking to strengthen your technical skills and stay ahead in the world of industrial automation? For engineers, technicians, and technical learners in East Malaysia, this is your chance to gain real-world experience without leaving your hometown. The free hands-on Mitsubishi Electric inverter training in Miri is a rare opportunity to learn directly from industry experts, featuring guided instruction using Mitsubishi Electric FR-D700 kits. Whether new to automation or looking to enhance your practical knowledge, this event delivers high-impact learning tailored to local needs.

Join Us for a Free Hands-On Mitsubishi Electric Inverter Training in Miri! Are you ready to explore the world of inverters and discover their practical applications in industrial systems? Ultech Engineering is proud to present an exclusive opportunity for technicians, engineers, and aspiring professionals — a Free Hands-On Mitsubishi Electric Inverter Training, happening right here in Miri, Sarawak.

Access to professional technical training is often concentrated in major urban centers like Kuala Lumpur, creating challenges for those in East Malaysia. To help bridge this gap, the upcoming inverter training in Miri will feature an experienced trainer from Mitsubishi Electric Sales Malaysia (MESM). The trainer has conducted inverter courses nationwide and will now bring that expertise directly to local participants. Unlike typical classroom seminars, this hands-on session offers direct interaction with inverter equipment.

With 15 complete FR-D700 training kits prepared, the session is limited to 30 participants, ensuring ample access to hardware, meaningful engagement with the trainer, and practical guidance. This focused format allows for more hands-on experience, more questions answered, and greater confidence gained, all in an environment built for real learning.

With only 15 training kits and a 2-to-1 participant-to-kit ratio, the inverter training session is designed to provide intensive hands-on learning in a focused and practical environment. This limited format allows participants to actively operate, configure, and troubleshoot real inverter hardware while benefiting from closer interaction with trainers for immediate feedback and clarification. The small group setup encourages deeper engagement, better knowledge retention, and a more efficient learning pace, minimizing downtime and maximizing exposure to core inverter functions. The event avoids large crowds and passive instruction by prioritizing quality over quantity, offering a more impactful and personalized learning experience. Early registration is highly recommended due to the limited number of seats available.

This training program represents a meaningful collaboration between Ultech Engineering and the Institution of Engineers Malaysia (IEM) Miri Branch, bringing together local commitment and global technology. It reflects a shared vision of empowering East Malaysia’s engineering talent through practical, industry-relevant education.

By leveraging Ultech Engineering’s technical expertise and IEM Miri’s institutional support, the event delivers a structured training experience that benefits both working professionals and aspiring engineers. It also demonstrates how public-private partnerships can strengthen local capacity and support technical upskilling.

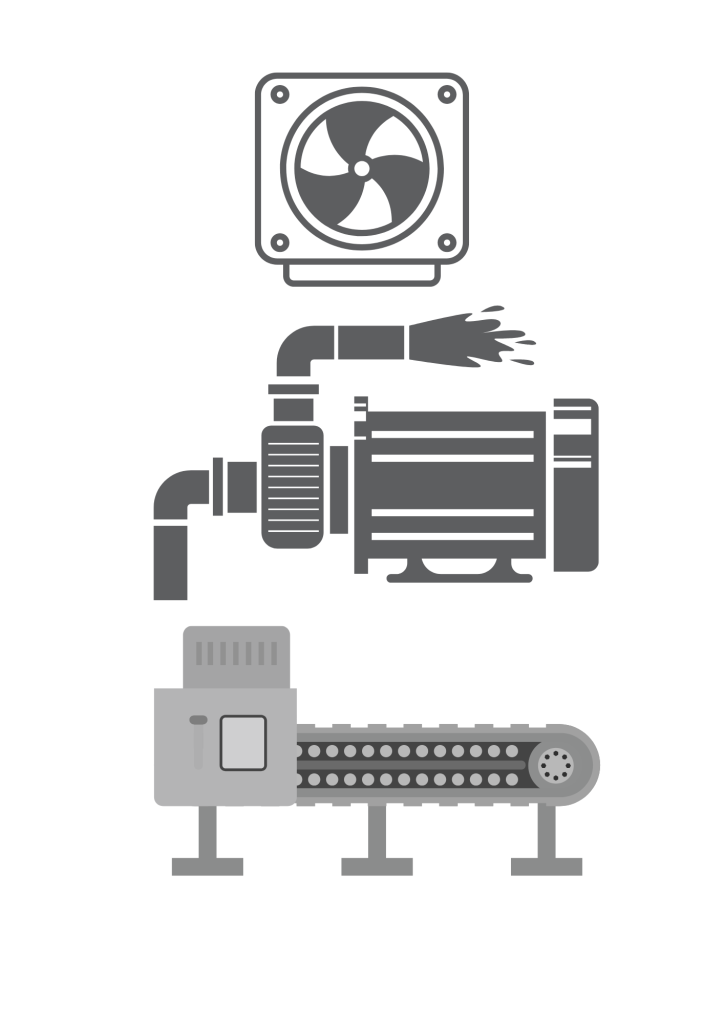

The FR-D700 inverter is widely used across industries such as automation, building services, water treatment, material handling, and HVAC systems, making it a practical tool for engineers and technical teams. Hands-on training with the FR-D700 equips participants with real-world skills like motor speed control, energy management, and reliable operation in systems such as conveyors, fans, pumps, lifts, and hoists. It also supports automation and smart integration in industrial environments. As industries increasingly focus on efficiency and safety, this training builds essential knowledge and confidence, contributing to long-term professional growth and a stronger engineering portfolio.

Despite its compact size, the FR-D700 offers powerful features like smooth low-speed motor control, built-in safety functions, and automatic energy-saving modes. The training will help participants understand how these functions impact real factory operations, contributing to reduced downtime, improved efficiency, and extended equipment lifespan, making it a valuable asset in modern industrial environments.

With increasing focus on sustainability and energy efficiency, optimizing inverter use has become a valuable skill. This training covers essential energy-saving functions of the FR-D700, parameter adjustments for smoother operation, and maintenance tips to extend inverter's lifespan. Even minor setup improvements can lead to significant cost savings, making this session beneficial for both individuals and companies aiming to enhance technical capabilities and reduce operational expenses.

One of the strongest aspects of this inverter training is that it’s designed for absolute beginners. You don’t need to be an automation expert or an experienced technician.

“Even if you have zero knowledge about inverters, this training is for you.”

The training begins with fundamentals:

From there, it gradually builds into real-life troubleshooting, parameter setting, and optimization. It’s a smooth learning curve, supported by top-tier trainers who are experienced in mentoring newcomers.

And by choosing the single-phase model, the organizers made a smart move, because single-phase 200V is more commonly available than three-phase power in many settings across Sarawak. This makes the training more relatable, more accessible, and easier to practice even at home or in small workshops.

Participants who complete the training will receive an official Inverter Training e-Certificate, endorsed by the organizing parties. This certificate serves as formal recognition of the skills and knowledge gained during the session. Whether added to a resume, professional profile, or company record, this certification validates practical competency in inverter basics and motor control — a useful credential for those looking to grow within the engineering, automation, or maintenance fields.

With strong demand and limited seating, this training is expected to fill quickly. For individuals who have always wanted to understand how industrial systems operate — or for those looking to advance their careers with real, applicable skills — this session offers a rare, entry-level gateway into the world of automation and inverter technology. Now is the time to take action and be part of a program that supports both personal development and professional growth.

This hands-on inverter training is officially approved for Continuing Professional Development (CPD) by the relevant professional body. Participants will earn structured CPD hours upon completion — a valuable addition for engineers and technical professionals maintaining professional registration or expanding their career credentials.

The FR-D700 series is Mitsubishi Electric’s trusted entry-level inverter, designed with powerful features and modern safety standards, making it ideal for real-world applications and beginner training alike. Here’s why it stands out:

The FR-D700 inverter features a built-in safety stop compliant with EU Machinery Directive and PLd/SIL2 standards, ensuring immediate motor shutdown during emergencies. Its cooling fan and capacitors are designed for a 10-year lifespan, offering long-term reliability. Additionally, a 4-digit password protection secures parameter settings against unauthorized changes.

The FR-D700 delivers 150% torque at 1Hz, ideal for applications like conveyors, hoists, and lifts. With magnetic flux vector control and an auto-tuning function, it ensures efficient, stable operation across various motor types.

The FR-D700 offers quick setup with an intuitive dial, allowing fast value jumps or precise adjustments with ease, supported by a nonslip design for better control. It also features enhanced RS-485 communication, now supporting speeds up to 38.4 kbps for more efficient integration and monitoring.

The FR-D700 features a compact, easily replaceable design with the same footprint as the FR-S500, allowing seamless upgrades. Its side-by-side mounting capability with no clearance needed helps save valuable panel space in control cabinets.4o

The FR-D700 is designed for easy maintenance with tool-free fan replacement for models 1.5kW and above, requiring no disassembly. Its comb-toothed wiring cover simplifies installation by allowing wiring to be completed before fitting the cover, saving time and keeping the setup clean.

Built-in EMC Filter Option

Designed to simplify compliance with the EMC Directive, the inverter reduces electromagnetic noise for smoother integration in sensitive environments. RoHS Compliant is fully compliant with the EU RoHS Directive, The FR-D700 uses materials that are safe for users and the environment.

This hands-on inverter training in Miri is more than just a course — it’s a strategic step toward developing stronger technical capabilities in East Malaysia. Designed for engineers, technicians, students, and individuals interested in automation, the program delivers tangible value and real-world skills that are both relevant and future-ready.

Key highlights of this training include:

By combining technology, education, and community partnership, this initiative helps build a stronger foundation for local talent. It reflects a long-term commitment to raising the standard of technical training and creating more opportunities for skill development in the region. This is not just a one-time session — it’s an investment in the future of engineering excellence in Miri and beyond.

Reserve your seat for the free hands-on inverter training in Miri by contacting us today. To register for this upcoming training program in Miri and to stay updated on the confirmed dates, please call or WhatsApp us at +6010-289 4133 with the following details:

Seats are filling up fast, so don’t miss your chance to be part of this exclusive event! Only 30 seats are available! We look forward to seeing you there. WhatsApp us at (+6010-2894133) to confirm your attendance now!