Significant advancements in technology have occurred since the wheel's invention in 3,500 B.C. The development of technology has enabled people to work and live in a more efficient and convenient manner. Over the course of history, hundreds of thousands of technological advancements have occurred, and as a result, some of the most vital everyday technologies have been overlooked or forgotten. Unbeknownst to the majority of individuals, components like servo motors contribute significantly to the daily smoothness of human life.

The subsequent sections of this article will elucidate the frequent utilisation of servo motors and other diminutive technological components in unexpected devices. It is also utilised in the industrial sector, where numerous products are manufactured. The following article shares a comprehensive understanding of Mitsubishi Electric servo motors, including their function, a list of commonplace objects and devices that utilise them, their benefits and drawbacks, as well as the names and functions of their constituent parts.

Servo motors or “servos”, as they are known, are electronic devices and rotary or linear actuators that rotate and push parts of a machine with precision. Servos are mainly used for angular or linear position and for specific velocity, and acceleration. Companies heavily use servo motors because of how compact and potent it is. Despite its size, it generates quite the amount of power and is known to be incredibly energy efficient.

Most of the companies that use servos are manufacturing companies that need it to position control surfaces and rotate objects at precise angles and distances. Most of the companies that use servo motors are manufacturing companies that use machines with servo motors.

There are two types of servo motors that are available and used in the industrial field.

First is the AC servo motor. This type of servo is currently used today by most companies. AC servo motors are mostly used in industrial fields. AC servo motors are AC motors that rely on encoders. These types of servo motors work through controllers providing feedback and closed-loop control. They are known to function at a high accuracy and are easily controllable.

Second is the DC servo motor. These kind of servo motors were used in the past and rarely used nowadays, as AC servo motors are easier to use, more effective, advanced, and reliable.

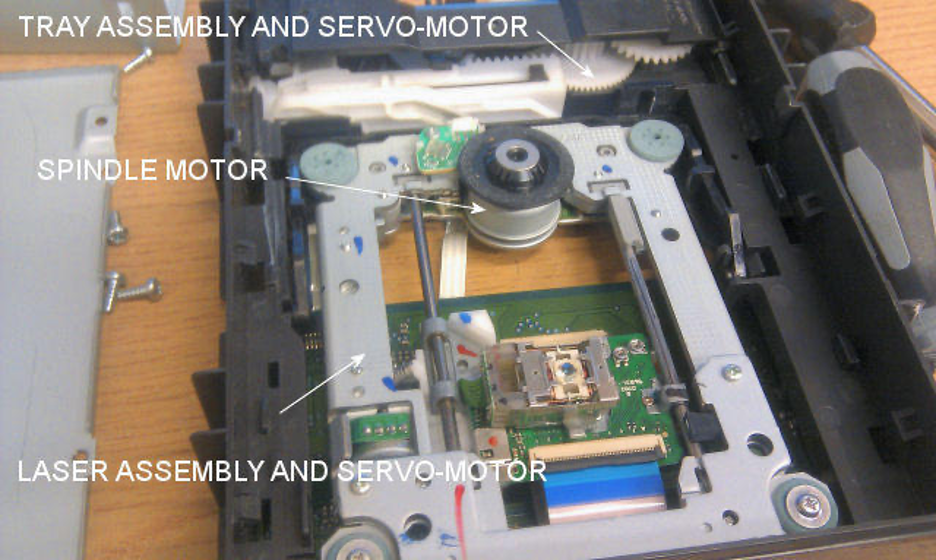

Servo motors are also utilized by items that are used every day. Home electronic devices like DVD and Blu-ray Disc players use servos to extract and retract disc trays.

A servo clutch system, commonly found in modern vehicles, integrates electronic and hydraulic components to automate clutch engagement and disengagement in manual transmissions. When the driver presses the clutch pedal, a position sensor signals the control unit, which then activates the hydraulic system to engage the clutch. Conversely, when the pedal is released, the system disengages the clutch. This technology enhances gear-shifting precision, reduces driver fatigue, and optimizes fuel efficiency by automating the clutch operation based on various driving conditions. Even commercial aircrafts also make use of servos to push and pull everything within the plane.

They are also used for novelty items such as remote-controlled and scale-sized toy cars, toy airplanes, toy helicopters, and toy robots. Servos are especially helpful for radio-controlled airplanes to position control surfaces.

But servos are mostly used for industrial purposes. Important industries such as robotics, pharmaceutics, food services and in-line manufacturing also make use of servos.

Servos are also most suited for electrically operated pieces of machinery such as elevators, rudders, walking robots, and operating grippers.

Nonlinear system identification involves the process of establishing a model for a nonlinear dynamic process, combining information derived from data with physical insight or prior knowledge. The system under consideration could be an experiment, a natural phenomenon, or a large-scale computer simulation. Dynamic responses of such deterministic systems may exhibit periodic or nonperiodic behavior.

This field encompasses a broad spectrum of techniques. At its core, the initial objective may be as simple as determining the number of states or modes required to construct a model for the system. Armed with this foundational information, a more intricate system identification process can unfold. On the detailed end of the spectrum is parametric system identification, where the differential equations of motion governing the system are known, but certain parameters remain unidentified.

Positioned between these extremes are approaches like non-parametric identification and nonlinear prediction, serving various purposes, from uncovering nonlinear restoring force characteristics to modeling dynamic behavior without explicitly determining the system's differential equations.

In the quest to tackle deviations from predictable patterns, known as non-linearities, advanced intelligent identification methods have emerged. These methods, such as Genetic Algorithm (GA), Ant Colony Optimization (ACO), Particle Swarm Optimization (PSO), and Glowworm Swarm Optimization (GSO), are proposed to overcome challenges in understanding the intricate characteristics of friction.

Among these methods, Glowworm Swarm Optimization (GSO) stands out for its efficiency and reduced dependency on prior knowledge, making it particularly well-suited for identifying friction parameters. Essentially, these cutting-edge techniques go beyond merely recognizing friction patterns; they pave the way for developing precise and efficient control strategies in the field of servo systems.

Model-based compensation strategies in the servo industry entail the utilization of identified mathematical models to counteract the impact of known factors, particularly friction and non-linearities, on servo systems. Engineers employ advanced identification methods to construct accurate models capturing the system's dynamics.

In scenarios involving parametric system identification, the general form of differential equations governing motion is known, but certain parameters are unidentified and need determination. Control strategies, including Proportional-Integral-Derivative (PID) control, neural network control, fuzzy control, and adaptive control, are then designed based on these identified models and parameters. The adaptability of these strategies allows tailoring to specific system characteristics, ultimately aiming to enhance servo system performance by mitigating the effects of friction and improving precision, response times, and overall accuracy in tracking desired trajectories or positions.

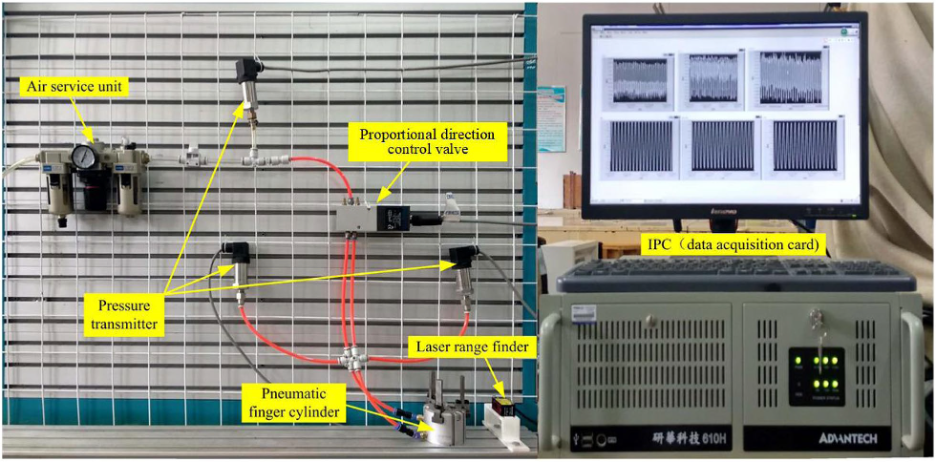

This section introduces an adaptive non-linear sliding mode control specifically designed for Mitsubishi Electric mechanical servo systems. This control method integrates glowworm swarm optimisation to identify friction-related issues, aiming to address the complexities of real-world systems.

The process involves using the GSO algorithm for offline identification of static and dynamic parameters within the LuGre friction model. Subsequently, the identified results are applied for a real-time online parametric estimation, enhancing accuracy and response time. Essentially, this adaptive approach not only acknowledges the challenges posed by real-world complexities but also demonstrates a forward-looking perspective on achieving precise control in Mitsubishi servo systems. In simpler terms, it's about developing smart, adaptive control methods to optimize the performance of Mitsubishi servo systems in the presence of friction-related challenges.

Complementing these advanced control strategies, Mitsubishi Electric offers a suite of servo motors solutions designed to meet the precision demands of adaptive control:

MELSERVO-J5 Series: Supporting a new network, CC-Link IE TSN, with servo amplifiers featuring high responsibility and rotary servo motors equipped with a high-resolution encoder.

MELSERVO-JET Series: High-performance servo amplifiers with a powerful control engine, connecting to CC-Link IE TSN for high-speed, high-precision control.

MELSERVO-J4: Balancing human-friendly and safety functions, high performance, and energy-saving considerations.

MELSERVO-JE: Applying servos to all machines with reliable basic performance and advanced ease-of-use.

MELSERVO-JN: Known for easy operation functions, high performance, and a compact body.

The servo support software further enhances the user experience, providing motor sizing, start-up, and servo adjustment support, making setup and tuning processes efficient and user-friendly. This comprehensive suite of offerings showcases Mitsubishi commitment to providing not just servo motors but complete solutions that empower users in achieving precision and efficiency.

In conclusion, the symbiosis of adaptive non-linear sliding mode control and Mitsubishi Electric servo motor solutions marks a significant stride towards precision and efficiency in mechanical servo systems. This comprehensive approach promises to usher in a new era of seamless automation, where optimal performance and adaptability converge to redefine the possibilities of industrial control. The collaboration between intelligent identification methods, robust control strategies, and advanced servo motor solutions propels industries into a future where precision is not just a goal but an inherent characteristic of automation.

No, running a servo motor in an open-loop control system is not practical since it is engineered to operate with real-time feedback and make adjustments accordingly. The servo motor relies on position, speed, or torque feedback to regulate its movements and maintain the desired setpoint. Therefore, it inherently functions as a closed-loop control system.

The main components of a servo motor are:

It works in closed-loop control for accurate output.

There are two types of AC servo motors:

There are three types of algorithms used:

Pulse width modulation, as its name suggests, alters the duration of pulses to dictate the motor's movement. A specific pulse duration in milliseconds corresponds to a specific degree of motor movement. The motor's speed is determined by the frequency of these pulses, with a higher frequency resulting in a faster motor speed.

A stepper motor moves in discrete steps; it does not move continuously. But a servo motor moves continuously.

Servo motors are electromechanical devices crucial for precise motion control in applications like robotics, relying on feedback systems for accuracy. In contrast, CNC (Computer Numerical Control) systems are computer-based controls used in machining operations, interpreting digital instructions to automate tasks such as milling and turning.

While servo motors are integrated components ensuring specific movements, CNC systems coordinate overall machine operations, enhancing efficiency in manufacturing processes. They often collaborate to achieve accurate and automated machinery performance.