In an era where industrial automation is transforming the way we manufacture and produce, the critical role of safety cannot be overstated. Mitsubishi Electric, a global trailblazer in automation solutions, takes a proactive and dedicated approach to safety by intricately weaving advanced safety protocols into their Programmable Logic Controller (PLC) programming. This comprehensive exploration seeks to delve into the nuanced layers of safety measures, underlining their unwavering commitment to ensuring the overall safety and security of automated processes.

Mitsubishi Electric commitment to safety extends far beyond the parameters of regulatory compliance. Safety is not merely a box to be checked but a fundamental principle that guides their entire approach to automation. The company's safety management system is a multifaceted framework that incorporates detailed risk assessments, meticulous safety design considerations, and a steadfast adherence to international safety standards. This holistic approach serves as the bedrock for creating automation solutions that are not just efficient but, more importantly, inherently safe.

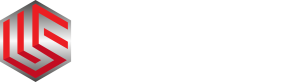

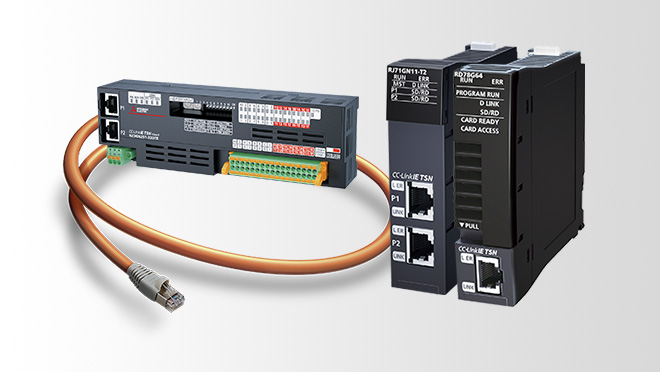

The PLCs engineered by Mitsubishi Electric stand out for their holistic suite of integrated safety functions. These functions go beyond the standard safety measures found in conventional PLCs. Mitsubishi Electric PLC programming empowers industries with tools that enable a dynamic and real-time response to potential risks. From the implementation of safety interlocks to the execution of emergency stop functions, and the continuous monitoring of safety parameters, ensures that their PLCs are at the forefront of creating safer and more secure industrial environments.

The advent of collaborative robots, or cobots, has reshaped the industrial landscape, ushering in an era where humans and machines work in tandem. Addressing this paradigm shift, Mitsubishi Electric seamlessly integrates safety-rated PLC programming that facilitates harmonious human-robot collaboration. The precision of their programming ensures that human operators and robots can work side by side without compromising safety, ushering in an era where efficiency and safety go hand in hand, creating workplaces that are not only productive but also safe.

Compliance with functional safety standards is not just a benchmark for Mitsubishi Electric it's a commitment to surpassing expectations. The company adheres rigorously to globally recognized standards such as ISO 13849 and IEC 61508. This commitment goes beyond regulatory requirements, reflecting dedication to setting the standard for excellence. By ensuring that their PLC programming adheres to these standards, the company guarantees the reliability and effectiveness of their automation systems on a global scale.

In the pursuit of continuous safety improvement, Mitsubishi Electric PLCs embrace a philosophy of real-time responsiveness. Beyond static safety measures, their PLCs are equipped with advanced monitoring and diagnostics capabilities. This real-time approach empowers operators to identify potential safety issues as they arise, allowing for immediate intervention and proactive maintenance. The result is a reduction in downtime, an enhancement of overall system reliability, and the assurance of a consistently safe working environment for all stakeholders.

Recognizing the diverse skill sets of engineers and programmers, Mitsubishi Electric places a premium on the accessibility of safety programming within their environments. The intuitive nature of their programming interfaces simplifies the process of implementing complex safety features. This democratization of safety programming ensures that a broader range of professionals, regardless of their expertise, can actively contribute to and benefit from enhanced safety measures, fostering a culture of safety across the industry.

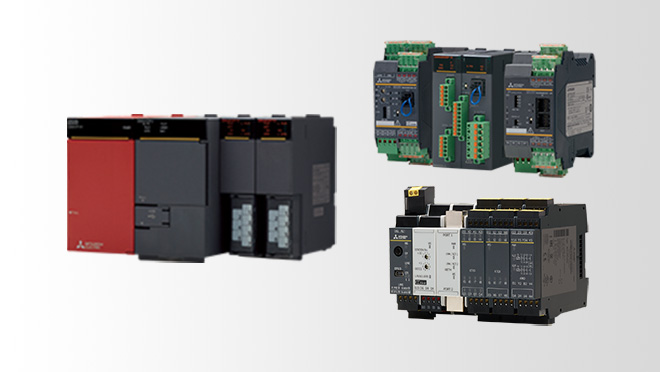

Flexibility is a hallmark of Mitsubishi Electric approach to safety within PLC programming. The PLCs support modular safety configurations, providing industries with the ability to scale and customize safety features according to the unique requirements of different applications. This modular approach ensures that safety measures can be tailored precisely to the demands of specific processes, creating a dynamic and adaptive safety framework that is responsive to the evolving needs of diverse industrial environments.

In the ever-evolving landscape of industrial automation, Mitsubishi Electric dedication to safety is not static; it's a dynamic commitment to continuous improvement. Regular updates and ongoing innovations in PLC programming demonstrate the company's proactive stance in staying ahead of emerging challenges and technological advancements. This commitment ensures that their automation solutions remain not only compliant with current safety standards but also future-proofed against the evolving complexities of the industrial landscape

In the bustling manufacturing landscape of Rockford, Illinois, kmV has emerged as a leading manufacturer and installer of automated vision inspection equipment, catering to a diverse range of industries including blow mold, preform and injection mold-container manufacturing, as well as the food, beverage, pharmaceutical, packaging, personal care, automotive, and household products sectors. With over a decade of experience and a commitment to excellence, kmV recently faced a challenge in streamlining their control platforms for enhanced efficiency and safety. This case study delves into kmV's collaboration with Mitsubishi Electric and how the integration of safety protocols in PLC programming has elevated automation safety to new heights.

kmV, in pursuit of a more seamless control platform, sought to reduce software engineering complexities while integrating visual display control in line with their vision control system. The existing dual interface system, comprising one interface for machine HMI and an external touch panel PC for machine vision aspects, presented hurdles in terms of structured programming, future expandability, and multiple product offerings. Recognizing the need for a unified solution, kmV aimed to mesh various product price points with a single source control platform.

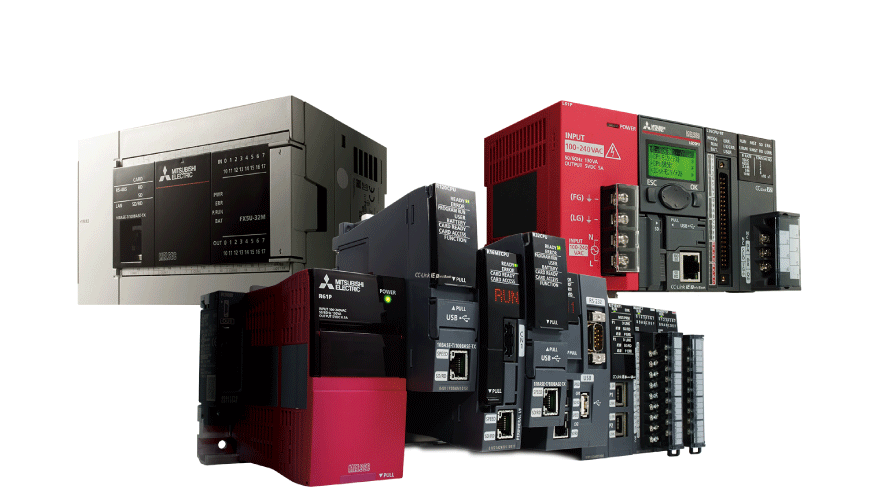

After careful consideration, kmV embraced comprehensive solution, featuring the MELSEC-Q Series PLC, GX Works2 Software, and the GT27 HMI. This integrated platform addressed kmV's requirements by providing a unified HMI for both machine control and vision control. The GX Works2 software, known for its structured programming capabilities, significantly reduced engineering time, resulting in 40 fewer hours per system. Mitsubishi Electric function blocks were utilized extensively, encapsulating functionality and allowing for a reusable and resalable structure.

The advantages of implementing Mitsubishi Electric solution were manifold. The unified HMI streamlined machine control and vision control seamlessly, enhancing operator interface intuitiveness. The system proved easy to expand, customize, and modify, ensuring future adaptability. The MELSEC-Q Series PLC, in conjunction with GX Works2, offered increased performance and robustness while significantly decreasing engineering time/system. The GT27 HMI provided an intuitive visualization interface, enabling effortless switching between the machine's vision interface and control systems.

In the pursuit of automation safety, Mitsubishi Electric platform played a pivotal role. The flexible MELSEC-Q Series modular PLC and GX Works2 configuration and programming software facilitated the integration of safety protocols within the system. Mitsubishi Electric function blocks allowed kmV to encapsulate safety functionality, ensuring a standardized and reliable approach to safety measures. This comprehensive safety integration not only met industry standards but also exceeded kmV's expectations in terms of reliability and performance.

By adopting Mitsubishi Electric platform, kmV successfully revised their machine's controls and interface platforms, resulting in increased performance, reliability, and a reduction of 40 engineering hours per system. The seamless integration with other kmV equipment, such as precision conveyance and container handling systems, further highlighted the versatility and efficiency of Mitsubishi Electric's solution.

In conclusion, the case study of kmV's collaboration with Mitsubishi Electric vividly illustrates the transformative impact of integrating safety protocols into Programmable Logic Controller (PLC) programming. The challenges faced by kmV in streamlining control platforms were not only met but exceeded through Mitsubishi Electric's comprehensive solution, featuring the MELSEC-Q Series PLC, GX Works2 Software, and the GT27 HMI.

The successful implementation of Mitsubishi Electric platform resulted in a unified Human-Machine Interface (HMI) that seamlessly combined machine control and vision control, addressing kmV's need for a streamlined and adaptable solution. The structured programming capabilities of GX Works2 significantly reduced engineering time, showcasing the efficiency gains offered by Mitsubishi Electric technology. The modular and flexible nature of the MELSEC-Q Series PLC allowed for the integration of safety protocols, ensuring a standardized and reliable approach to automation safety.

The collaborative efforts between kmV and Mitsubishi Electric not only met the industry standards for safety but also exceeded expectations in terms of reliability and performance. The reduction of 40 engineering hours per system underscored the practical benefits of Mitsubishi Electric solution, emphasizing its capacity to enhance not only efficiency but also the overall safety of automated processes.

This case study serves as a testament to unwavering commitment to safety as a core principle in PLC programming. By providing a dynamic and adaptive safety framework, Mitsubishi Electric empowers industries to create safer and more secure industrial environments. As automation continues to evolve, the proactive stance in continuous innovation and updates ensures that their solutions remain at the forefront of addressing emerging challenges and technological advancements, contributing to the ongoing transformation of industrial automation.