The industrial sector is continually evolving, with increasing demands for efficiency, safety, and scalability. One significant development in this field is the Modular Motor Control Center (MCC) solution, compliant with IEC 61439. Developed through a collaboration between Allen-Bradley and CUBIC, this innovative system offers unparalleled flexibility, reliability, and operational efficiency, setting a new standard for industrial automation.

IEC 61439 is an international standard set by the International Electrotechnical Commission (IEC) that specifies the requirements for low-voltage switchgear and controlgear assemblies. It ensures these assemblies, which include components like circuit breakers and switches, meet stringent safety, reliability, and performance criteria. Applicable across various industries, IEC 61439 mandates rigorous design, construction, testing, and verification processes to guarantee assemblies function properly under normal and fault conditions.

One of the key benefits of IEC 61439 is its support for modular and customizable designs, allowing assemblies to be tailored to specific operational needs while maintaining compliance. This flexibility is essential for industries with unique requirements and varying scales of operation. The standard is globally recognized and adopted, facilitating international trade and ensuring consistent safety and performance standards worldwide.

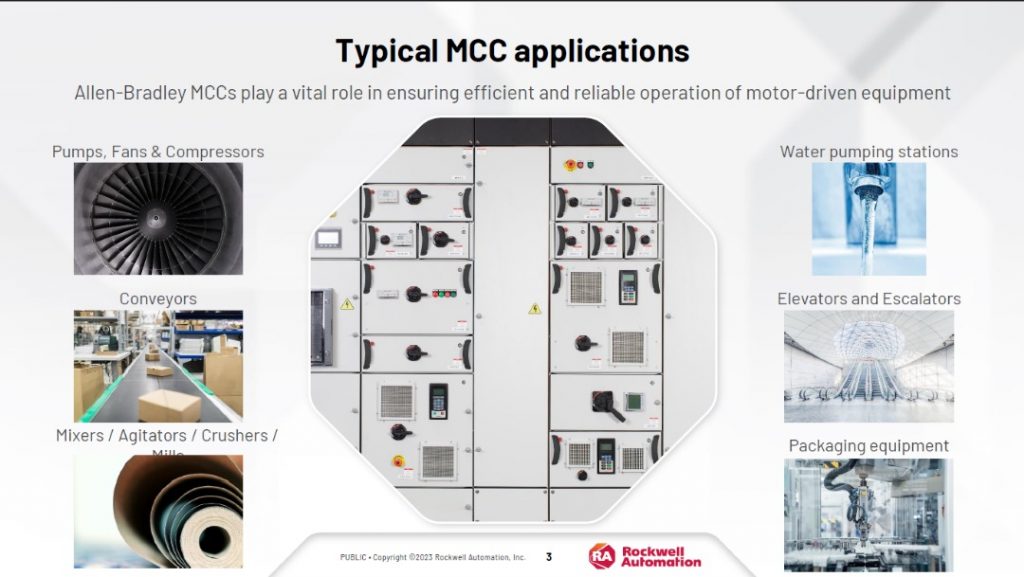

Motor Control Centers (MCCs) play a critical role in industrial environments, serving as centralized systems that streamline motor control processes. Without MCCs, factories face numerous challenges, including complex wiring, inefficient space utilization, and maintenance difficulties. The Allen-Bradley MCCs, integrated with the CUBIC Modular System, provide a robust solution to these issues, enhancing overall production efficiency and safety.

Motor Control Centers are integral to the operational success of various industries. They centralize the control of multiple motors, making it easier to manage and maintain the entire motor system. This centralization not only simplifies the control process but also significantly reduces wiring complexity, leading to lower installation and maintenance costs. Additionally, MCCs help optimize space utilization in industrial settings, allowing for a more organized and efficient workspace.

The system features a variety of essential components, including air circuit breakers, moulded case circuit breakers, motor protection circuit breakers, disconnect switches, electronic overload relays, and programmable controller integration. These components ensure the MCC can meet the diverse requirements of different industrial applications. These applications benefit from the system’s flexibility, safety, and efficiency, ensuring reliable and optimized operation. The CUBIC Modular System is versatile and can be used in a variety of applications, including:

This feature simplifies the design, construction, and installation of electrical switchboards.

The CUBIC Modular System is highly flexible, allowing for easy adjustments and scalability. It provides a robust platform for LV Switchboards, power distribution boards, motor control centers, and standard enclosures.

The system complies with IEC 61439 standards, ensuring high safety and reliability. It also features compliance with other global standards, such as IEC 60529 (Ingress Protection Rating) and IEC 60068-2-57 (Seismic).

The system includes a range of components like air circuit breakers, motor protection circuit breakers, and variable frequency drives, ensuring a complete solution for any application.

The CUBIC Modular System provides highly flexible and scalable smart motor control solutions for your Modular MCC. This ensures that your systems can grow and adapt as your operational needs change, maintaining efficiency and performance.

CUBIC Modular MCCs incorporate robust networks that provide access to critical data, enhancing productivity and sustainability. These networks enable real-time monitoring and control, helping you make informed decisions and optimize your processes.

By using CUBIC Modular MCCs, you can improve plant floor safety and reliability. Compliance with stringent standards ensures that all components meet high safety requirements, reducing the risk of accidents and downtime.

CUBIC Modular MCCs help elevate productivity and maximize the use of your vital assets. The efficient design and robust performance of the system ensure that your operations run smoothly, minimizing downtime and maximizing output.

The CUBIC Modular MCC solution boasts impressive technical specifications, ensuring compliance with rigorous global standards:

The system meets the IEC 61439-1 & -2: 2020 standards for low voltage switchgear and controlgear assemblies. It also complies with other relevant standards, ensuring safety and reliability.

The Modular MCC operates at a rated voltage of up to 1000VAC, with a main busbar current rating of up to 6,300A and a distribution busbar current rating of up to 2000A.

The MCC provides a high degree of protection, with enclosure ratings ranging from IP31 to IP54. It also features internal separation forms 2B, 3B, and 4B, ensuring safe and reliable operation.

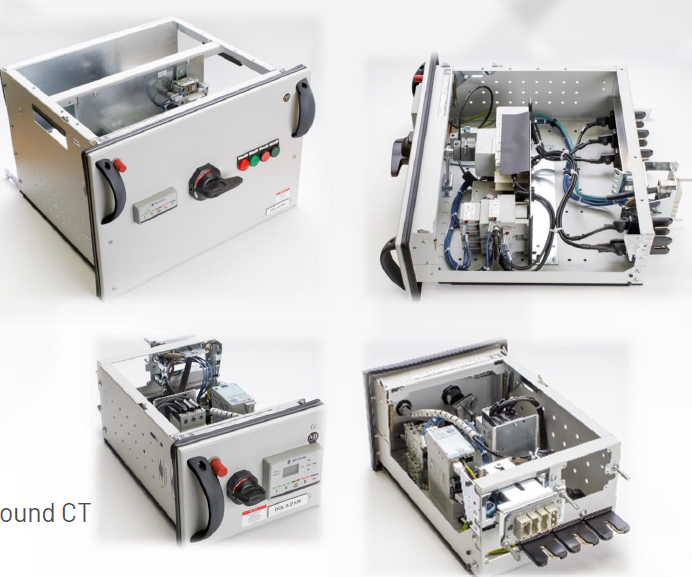

The Modular MCC is available in fixed-type, plug-in type, and drawout-type functional units. This versatility allows for easy maintenance and customization according to specific requirements.

The CUBIC Modular MCC solution is designed to offer flexibility, scalability, and efficiency, making it a future-proof investment for any industrial operation. Its compliance with global standards, robust protection features, and versatile design options make it a superior choice for enhancing industrial efficiency and reliability.

The Modular MCC solution offers numerous benefits to customers, enhancing operational efficiency, safety, and sustainability. By optimizing space usage, improving energy management, and reducing downtime, it provides a strategic advantage for industries where these factors directly impact performance and profitability.

The modular design reduces wiring complexity and optimizes space utilization, leading to a more organized and efficient workspace. This optimization is crucial for industries with limited floor space and complex motor control requirements.

The MCC's advanced components and integration capabilities promote energy efficiency, reducing operational costs and environmental impact. This efficiency is particularly important for industries looking to minimize their carbon footprint and achieve sustainability goals.

The MCC's robust design and built-in safety features minimize downtime and ensure continuous operation. This reliability is critical for industries where downtime can result in significant financial losses and operational disruptions.

The modular components can be individually accessed and serviced, simplifying maintenance and reducing the time required for repairs. This efficiency is essential for industries with complex motor control systems that require regular maintenance and upgrades.

The MCC's compliance with global standards and built-in safety features ensure a high level of safety for operators and equipment. This safety is crucial for industries where electrical faults and malfunctions can pose significant risks.

The FLEXLINE 3500 is a motor control center (MCC) designed by Rockwell Automation specifically for IEC markets. It is engineered to meet the requirements of the IEC 61439 standard, a key specification for low-voltage switchgear and control gear assemblies. The FLEXLINE 3500 MCC is part of Rockwell Automation's broader portfolio of motor control solutions designed for global markets, providing robust and reliable control for complex industrial processes.

The CUBIC Modular MCC solution is designed and tested to meet the highest standards of safety and reliability, adhering to the following globally recognized certifications:

The CUBIC Modular System from Rockwell Automation is a powerful solution for creating tailor-made enclosures using IEC 61439-certified hardware and ancillaries for your Modular MCC. With its modularity, brand agnosticism, and comprehensive support, it addresses the most crucial demands of modern industrial setups. By integrating with Rockwell Automation’s smart systems, it offers unparalleled flexibility, scalability, and efficiency, making it an ideal choice for any application. Empower your industrial solutions with CUBIC Rockwell Automation and experience the future of modular systems today.