At Ultech Engineering, we're thrilled to present an exciting showcase of our past project cases in the realm of oil and gas automation. As we gear up for OGA 2023, we've put together a captivating video that provides a comprehensive glimpse into our expertise and accomplishments in this dynamic industry. Our solutions encompass a wide range of offerings, including explosion-proof switchboards, control panels, and marine switchboards, each tailored to meet the unique demands of oil and gas operations.

In this video, you'll have the opportunity to explore some of our most notable project references, allowing you to witness firsthand the innovation and dedication that define Ultech Engineering. Here's a brief overview of what you can expect:

1. Ex-Proof Switchboards and Control Panels: Our expertise in designing and manufacturing explosion-proof switchboards and control panels has been instrumental in enhancing safety and efficiency across various oil and gas facilities. These solutions are engineered to withstand hazardous environments, ensuring the seamless operation of critical systems.

2. Marine Switchboards: Operating at sea presents its own set of challenges and requirements. Ultech Engineering has risen to the occasion by delivering marine switchboards that meet stringent quality standards. Our solutions are designed to withstand the harsh conditions of the marine environment, ensuring uninterrupted performance when it matters most.

3. Past Project References: Dive into our video to discover some of our most remarkable past projects. We'll take you through a journey of successful installations, highlighting the intricacies of our work, our commitment to excellence, and our unwavering focus on precision engineering.

As we eagerly anticipate OGA 2023, we extend a warm invitation to all industry professionals and enthusiasts. Join us at the Kuala Lumpur Convention Centre from September 13-15, where you can experience our cutting-edge solutions firsthand. Our booth, located at Hall 7, booth number 7705, will be the hub of innovation and expertise.

Don't miss this opportunity to connect with our team, explore our offerings, and discuss how Ultech Engineering can elevate your oil and gas automation projects. We look forward to meeting you in person and sharing our passion for engineering excellence. See you at OGA 2023!

The video presentation highlighted several remarkable projects, from the Fuel Gas Superheaters, the Emergency Diesel Generator Control Panel, the Firewater Pump Control Panels, and more. Each project serves as a testament to Ultech Engineering's commitment to excellence, innovation, and precision in factory automation and power systems design and integration.

In each section, we will delve into the specific details of each project, including its purpose, design considerations, and the critical role it plays in the respective industrial systems. Additionally, we will showcase images to provide a visual understanding of our work and highlight the aesthetics, functionality, and reliability of Ultech Engineering's control panels in real-world applications. Let's begin our journey through these remarkable projects, starting with the Fuel Gas Superheater.

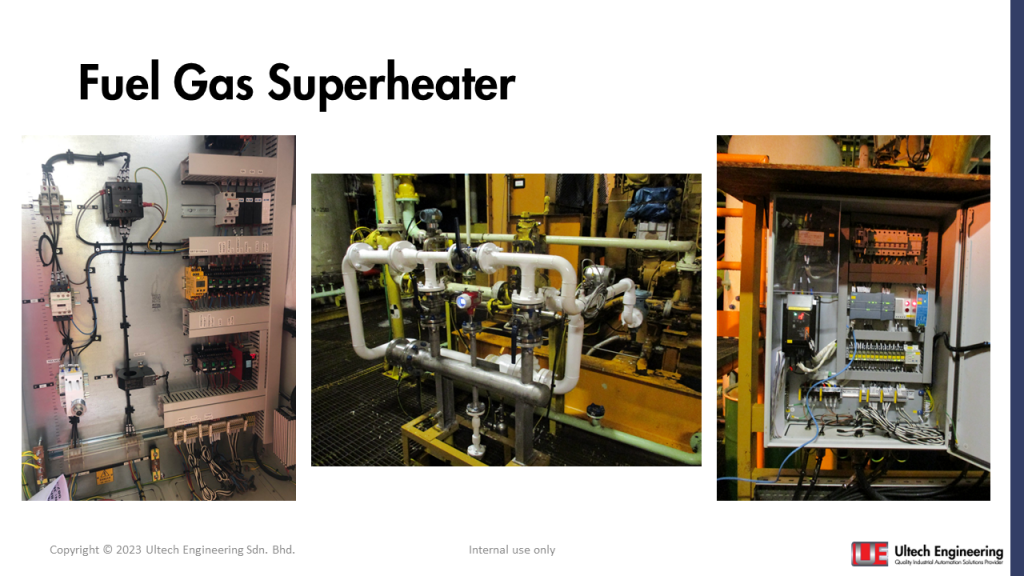

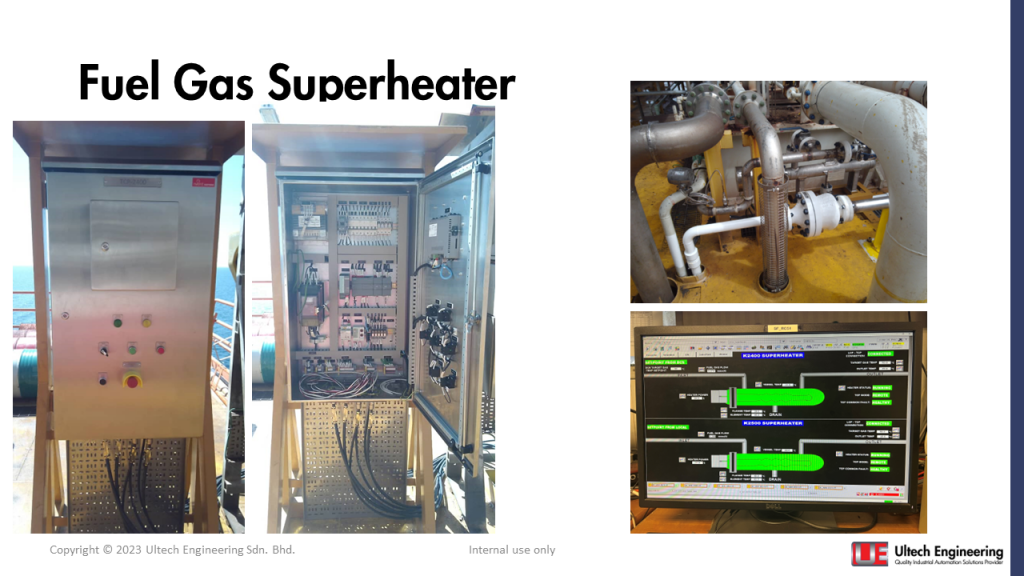

In response to the challenges posed by high humidity levels in the fuel gas supply at the North Sabah Field, Ultech Engineering embarked on a critical project to commission six sets of Fuel Gas Superheaters. This initiative aimed to mitigate nuisance tripping caused by moisture content in the fuel gas, ensuring uninterrupted operations and enhanced reliability in the field.

The primary objective of the Fuel Gas Superheater project was to address the issue of nuisance tripping attributed to high humidity levels in the fuel gas. By installing superheaters, Ultech Engineering aimed to raise the temperature of the fuel gas to optimal levels, thereby reducing the risk of tripping and ensuring consistent and reliable supply to the engines.

The project spanned across multiple years, with two sets of Fuel Gas Superheaters commissioned each year from 2021 to 2023. The deliverables included the supply of Control Panels and Heaters tailored to the specific requirements of the North Sabah Field. Additionally, Ultech Engineering ensured seamless integration of the Heater control panels with the existing Engine Local Control Panels (LCP), facilitating centralized control and monitoring of the superheater system.

The successful commissioning of the Fuel Gas Superheaters at the North Sabah Field underscores Ultech Engineering's commitment to delivering innovative solutions that address critical operational challenges. By mitigating nuisance tripping and enhancing operational reliability, the superheaters have contributed to the smooth and efficient functioning of the field, ensuring uninterrupted supply and operation of vital equipment. Ultech Engineering remains dedicated to pushing the boundaries of engineering excellence, empowering industries to overcome obstacles and achieve sustainable success.

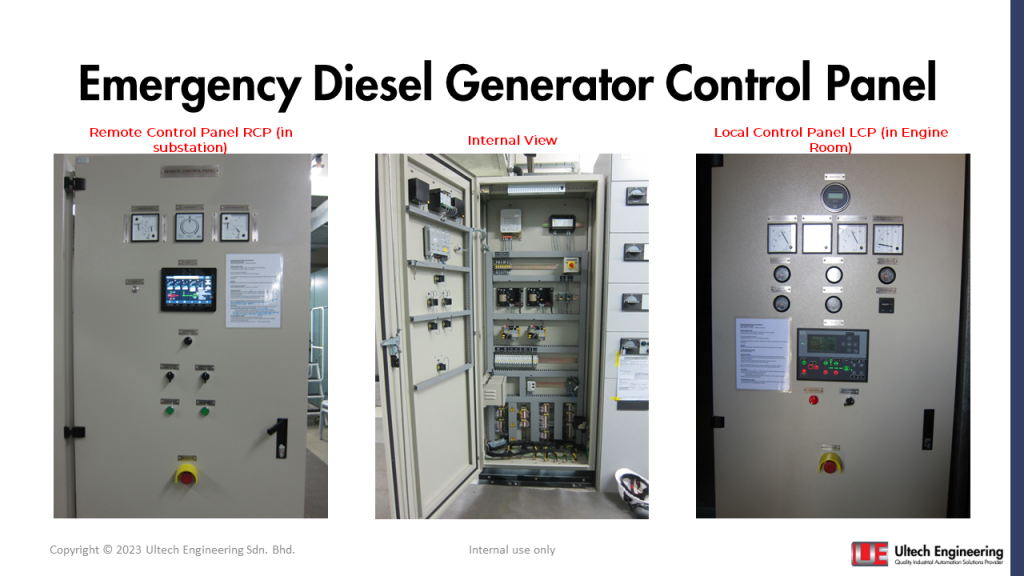

In response to the critical need for a reliable Emergency Diesel Generator (EDG) system, Ultech Engineering undertook a comprehensive project to commission a state-of-the-art EDG control panel. This initiative aimed to enhance the EDG system's functionality, reliability, and integration capabilities, ensuring seamless operation during emergency scenarios and power outages.

The primary objective of the EDG Control Panel project was to upgrade the existing control panel to incorporate essential features such as Auto Mains Failure (AMF) and Synchronization functions. Additionally, Ultech Engineering aimed to supply, install, and commission both local and remote control panels, facilitating convenient monitoring and control of the emergency genset system.

Ultech Engineering delivered a turnkey solution, encompassing the supply, installation, and commissioning of both local and remote control panels for the emergency genset system. The integration of these control panels provided operators with convenient access to real-time monitoring and control functionalities, enhancing operational efficiency and responsiveness.

The successful commissioning of the Emergency Diesel Generator (EDG) Control Panel project exemplifies Ultech Engineering's commitment to delivering innovative and reliable solutions for critical infrastructure systems. Ultech Engineering has enhanced the reliability, efficiency, and safety of the emergency genset system by upgrading the control panel with advanced functionalities and ensuring seamless integration with the existing switchboard. This project underscores Ultech Engineering's dedication to engineering excellence and customer satisfaction, empowering industries to navigate challenges and achieve operational resilience.

In response to the critical need for reliable fire protection systems, Ultech Engineering embarked on a significant project to commission advanced Firewater Pump (FWP) control panels. This initiative aimed to upgrade existing control panels using state-of-the-art PLC and HMI technology, ensuring optimal functionality, compliance with NFPA 2.0 standards, and enhanced reliability in fire suppression operations.

The primary objective of the FWP Control Panel project was to modernize and upgrade existing control panels for Diesel Driven and Motor Driven Firewater Pumps. By leveraging PLC and HMI technology, Ultech Engineering aimed to enhance control capabilities, automation, and monitoring functionalities, ensuring swift and effective response to fire emergencies. Moreover, adherence to NFPA 2.0 standards was paramount to ensure compliance and reliability in critical fire protection systems.

Ultech Engineering delivered a turnkey solution, encompassing the commissioning of four sets of Diesel Driven FWP control panels, two sets of Jockey Pump control panels, and two sets of 6.6kV Motor Driven FWP control panels. Each control panel was meticulously engineered and built to meet NFPA 2.0 standards, ensuring compliance and reliability in fire protection systems.

The successful commissioning of the Firewater Pump (FWP) Control Panel upgrade project exemplifies Ultech Engineering's commitment to delivering innovative, reliable, and compliant solutions for critical fire protection systems. By leveraging advanced PLC and HMI technology and adhering to NFPA standards, Ultech Engineering has enhanced control capabilities, automation, and reliability in fire suppression operations. This project underscores Ultech Engineering's dedication to engineering excellence and safety, empowering industries to safeguard assets, protect personnel, and mitigate fire risks effectively.

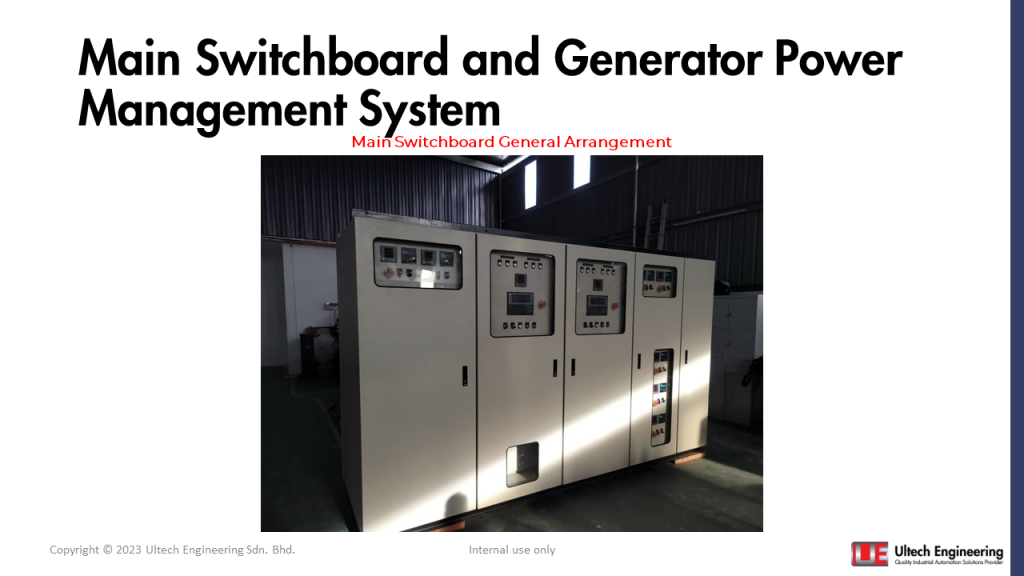

Ultech Engineering embarked on a comprehensive project to design and fabricate a Main Switchboard (MSB) integrated with a Generator Power Management System (PMS) for CIC Environmental Services in Brunei. This initiative aimed to modernize and upgrade the generator Power Distribution System, incorporating advanced features such as Automatic Changeover, remote monitoring, and control capabilities.

The primary objective of the MSB and PMS project was to enhance the efficiency, reliability, and safety of the generator Power Distribution System. By integrating advanced functionalities such as Automatic Changeover, remote monitoring, and control system, Ultech Engineering aimed to streamline operations, improve system responsiveness, and ensure seamless power distribution during both routine and emergency scenarios.

Ultech Engineering delivered a turnkey solution, encompassing the design, fabrication, and integration of the MSB with the PMS for CIC Environmental Services in Brunei. The system was meticulously engineered to meet the specific requirements and operational needs of the client, ensuring seamless integration and optimal performance.

The successful integration of the Main Switchboard (MSB) with the Generator Power Management System (PMS) underscores Ultech Engineering's commitment to delivering innovative, reliable, and efficient solutions for critical power distribution systems. Ultech Engineering has enhanced system efficiency, reliability, and safety by incorporating advanced features and functionalities, empowering clients to achieve seamless power distribution and management in diverse operational environments. This project exemplifies Ultech Engineering's dedication to engineering excellence and customer satisfaction, ensuring the highest quality and performance standards in every solution delivered.

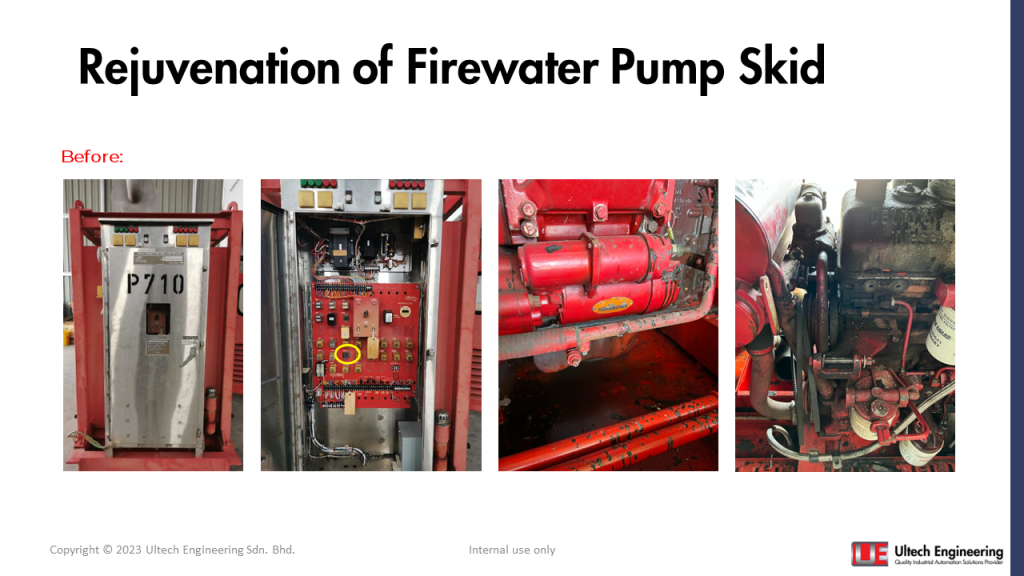

Ultech Engineering embarked on a significant project focused on the rejuvenation of a Firewater Pump (FWP) Skid, encompassing the replacement of outdated control panel systems and the overhaul of the FWP skid itself. This initiative aimed to modernize and optimize the functionality, reliability, and efficiency of the FWP system, ensuring enhanced fire protection capabilities in critical industrial environments.

The primary objective of the FWP Skid rejuvenation project was to upgrade the existing control panel from a hardwired design to a state-of-the-art PLC control system. By implementing PLC technology, Ultech Engineering aimed to improve system reliability, ease of troubleshooting, and scalability. Additionally, the overhaul of the FWP skid aimed to restore and enhance its operational performance, ensuring reliable and efficient firewater pumping operations.

Ultech Engineering delivered a comprehensive solution, encompassing the replacement of the control panel with a PLC system and the overhaul of the FWP skid. The project included design, fabrication, installation, and commissioning activities to ensure seamless integration and optimal performance of the rejuvenated FWP system.

The successful rejuvenation of the Firewater Pump (FWP) Skid exemplifies Ultech Engineering's commitment to delivering innovative and reliable solutions for critical industrial applications. By upgrading the control panel to a PLC system and overhauling the FWP skid, Ultech Engineering has enhanced the functionality, reliability, and efficiency of the FWP system, ensuring seamless fire protection capabilities in demanding operating environments. This project underscores Ultech Engineering's dedication to engineering excellence and customer satisfaction, empowering industries to achieve optimal performance and safety in their operations.

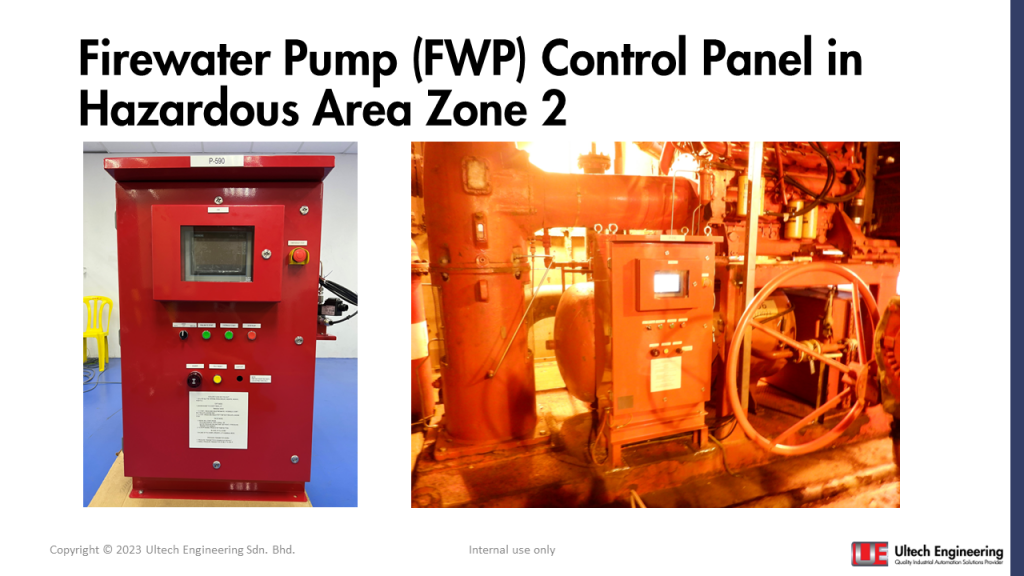

Ultech Engineering undertook a critical project involving the rejuvenation of a Firewater Pump (FWP) Skid, focusing on the replacement of the control panel and engine while ensuring compliance with hazardous area regulations. This project was crucial for enhancing fire protection capabilities in hazardous environments, where safety and reliability are paramount.

The primary objective of the FWP Control Panel project in Hazardous Area Zone 2 was to upgrade the existing hardwired control panel to a modern PLC-based system. This transition aimed to improve system reliability, ease of troubleshooting, and expandability. Additionally, the overhaul of the FWP skid sought to restore and enhance its operational performance, ensuring reliable firewater pumping operations in hazardous areas.

Ultech Engineering delivered a comprehensive solution, including the replacement of the control panel with a PLC-based system and the overhaul of the FWP skid to comply with hazardous area regulations. The project encompassed design, fabrication, installation, and commissioning activities to ensure seamless integration and optimal performance in hazardous environments.

The successful implementation of the Firewater Pump (FWP) Control Panel in Hazardous Area Zone 2 underscores Ultech Engineering's commitment to delivering innovative and compliant solutions for critical industrial applications. By upgrading the control panel to a PLC-based system and overhauling the FWP skid, Ultech Engineering has enhanced safety, reliability, and efficiency in hazardous environments, ensuring seamless fire protection capabilities while complying with stringent regulations. This project demonstrates Ultech Engineering's expertise in hazardous area installations and its dedication to engineering excellence and customer satisfaction.

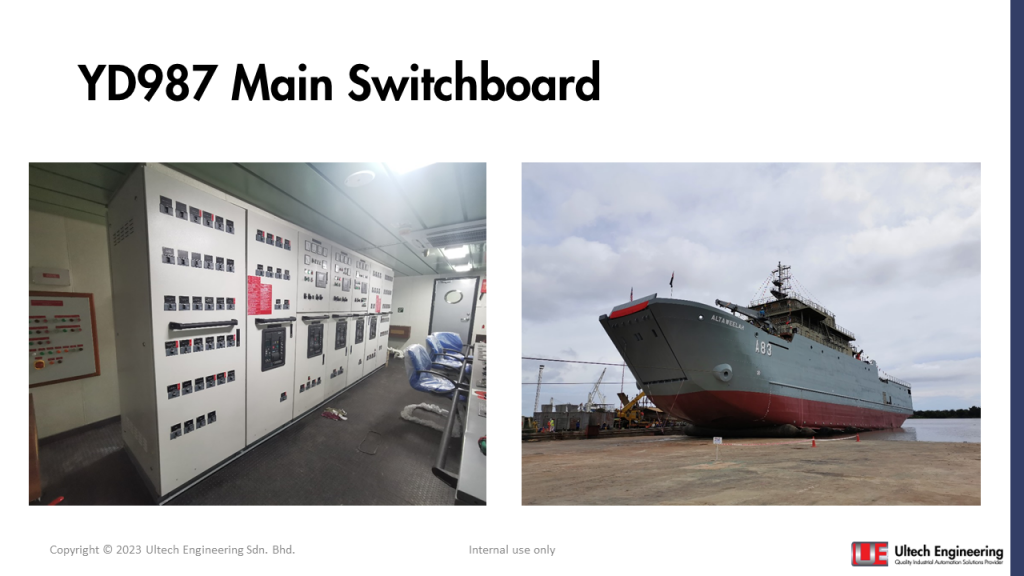

Ultech Engineering embarked on a significant project to design, fabricate, integrate, test, and commission the overall electrical power distribution and control system for the YD987 80M Training Vessel, commissioned by the United Arab Emirates Navy. This project was instrumental in ensuring reliable and efficient electrical power management onboard the vessel, essential for training and operational readiness.

The scope of the project encompassed the entire electrical power distribution and control system for the YD987 Training Vessel. This included the design, fabrication, integration, testing, and commissioning of various components such as the Main Switchboard, Power Management System (PMS), Ship Monitoring & Control System, and various Motor Starting Panels.

Ultech Engineering delivered a turnkey solution, encompassing the design, fabrication, integration, testing, and commissioning of the Main Switchboard and associated electrical power distribution and control components for the YD987 Training Vessel. The project was meticulously executed to meet the stringent requirements and specifications of the United Arab Emirates Navy.

The successful completion of the YD987 Main Switchboard project exemplifies Ultech Engineering's expertise in designing, integrating, and commissioning complex electrical power distribution and control systems for maritime applications. By delivering a reliable, efficient, and compliant solution, Ultech Engineering has contributed to the operational readiness and safety of the YD987 Training Vessel, supporting the training and mission requirements of the United Arab Emirates Navy. This project underscores Ultech Engineering's commitment to engineering excellence, innovation, and customer satisfaction in the maritime industry.