In today's rapidly evolving industrial landscape, modern Human-Machine Interface (HMI) solutions play a crucial role in improving efficiency, driving innovation, and optimizing the performance of industrial operations. One such solution that stands out is FactoryTalk® Optix™, a cutting-edge, scalable HMI visualization platform from Rockwell Automation. Whether for greenfield or brownfield projects, FactoryTalk Optix provides a flexible, future-proof solution for companies looking to upgrade their industrial operations.

Human-Machine Interface (HMI) is a technology that forms the essential link between humans and machines in industrial automation. An HMI is essentially the screen or device through which an operator interacts with a system, giving commands, monitoring operations, and receiving feedback from machinery. In today’s industrial setups, HMIs play a crucial role in improving efficiency, ensuring safety, and making complex processes more manageable.

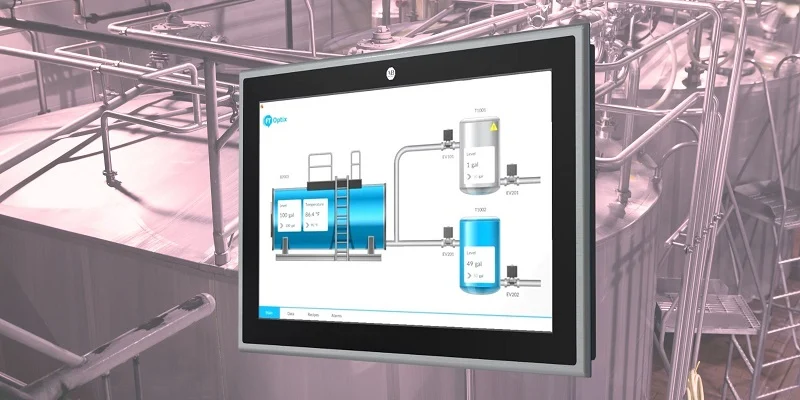

An HMI is a platform that allows interaction between the operator and the machine. It can be a simple touchscreen panel, a computer interface, or even a mobile device app. Typically, HMIs are integrated into industrial machinery, such as manufacturing equipment, power plants, and automated production lines. The interface often displays real-time data, controls, and alarms, allowing operators to monitor and adjust processes with just a few taps.

HMI systems can range from basic panels with limited functionality to highly advanced systems that support data analytics, predictive maintenance, and remote access. They often work hand-in-hand with Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems to streamline industrial operations.

With advancements in technologies like the Internet of Things (IoT) and artificial intelligence, HMI systems are becoming even more powerful. Future HMIs may offer predictive maintenance insights, voice-command capabilities, and augmented reality features, making industrial automation smarter and more intuitive.

HMI technology is essential for enhancing productivity, ensuring safety, and optimizing decision-making in industrial settings. As industries embrace digital transformation, HMIs will continue to evolve, playing an even more central role in the seamless operation of automated systems.

FactoryTalk Optix is a cloud-enabled HMI platform that facilitates the design, testing, and deployment of industrial applications. It offers a flexible and open architecture, allowing for the seamless integration of both Rockwell Automation and third-party devices. Its modern approach provides users with new levels of collaboration, scalability, and interoperability, making it the ideal choice for a wide range of industries, including manufacturing, food and beverage, automotive, and more.

The platform is designed to improve operational processes by delivering real-time data visualization, ensuring enhanced decision-making, and boosting productivity.

When it comes to greenfield projects, companies have the unique advantage of starting from scratch, which means they can integrate the most advanced HMI solutions right from the beginning. FactoryTalk Optix offers the following benefits for new industrial setups:

For brownfield projects, where existing systems and infrastructures are already in place, upgrading to a new HMI platform can be challenging. FactoryTalk Optix simplifies this process with features like:

FactoryTalk Optix caters to various industries, providing tailored solutions to address specific operational challenges. Key industry applications include:

The versatility of FactoryTalk Optix is not limited to industrial operations alone. Businesses with complex operations, particularly those with remote assets or facilities, can also benefit from its range of features:

A manufacturing plant in the automotive industry implemented FactoryTalk Optix to upgrade its existing HMI systems. The plant was previously using multiple HMI platforms, each with its own set of challenges related to connectivity and data visibility. By migrating to FactoryTalk Optix, the plant achieved the following:

A financial services firm managing critical data centers across multiple locations used FactoryTalk Optix to centralize its asset management operations. The platform’s cloud-enabled features allowed the firm to:

FactoryTalk® Optix™ offers an open, scalable Human-Machine Interface (HMI) visualization platform that is specifically designed to meet the diverse needs of modern industrial environments. This flexibility makes it suitable for both greenfield and brownfield projects, addressing a range of industry-specific requirements and enabling easy adaptation to different hardware configurations and connectivity options. Below are some tips that help you design highly functional and user-friendly HMI touchpoints:

By applying these tips, you can create an effective SCADA-HMI integration that enhances operational efficiency, maintains secure data flow, and provides operators with the tools they need to control and monitor advanced industrial processes effectively. FactoryTalk Optix and FactoryTalk Hub’s capabilities provide an ideal platform for designing intuitive, well-connected HMI systems that complement SCADA functions.

FactoryTalk® Optix™ and FactoryTalk® Hub™ are both part of Rockwell Automation's ecosystem but serve different purposes in industrial automation. Allen-Bradley OptixPanel™, PanelView™, and the aforementioned products are all components of Rockwell Automation's HMI (Human-Machine Interface) offerings, each serving different roles in visualization and control within industrial environments. Here’s a comparison of each solution:

FactoryTalk Optix: HMI Visualization Platform

FactoryTalk Optix is an HMI (Human-Machine Interface) visualization platform designed for creating, managing, and deploying real-time data visualization in industrial environments. It is specifically developed to meet the needs of greenfield and brownfield projects, allowing for scalable deployment and customization across various hardware platforms.

Key Features of FactoryTalk Optix:

Visualization and Control: Provides a powerful interface for monitoring, controlling, and visualizing industrial processes.

Open Architecture: Built on open standards such as OPC UA and MQTT, allowing integration with both Rockwell and third-party devices.

Scalability and Flexibility: Supports a range of deployment options, from Runtime Lite for smaller systems to Pro configurations for larger-scale applications.

Design Environment (Optix Studio): FactoryTalk Optix Studio is the design tool used to build and test HMI applications. It can be installed locally or accessed through FactoryTalk Hub in a cloud-based environment, enabling collaborative development.

Remote Access: Includes FactoryTalk Remote Access, allowing operators to manage devices, troubleshoot, and deploy updates remotely.

FactoryTalk Optix is best suited for companies looking to implement or upgrade their HMI systems with a highly customizable, scalable, and interoperable platform.

FactoryTalk Hub: Cloud-Based Collaboration and Development Platform

FactoryTalk Hub is a cloud-based platform that provides centralized tools and resources for collaborative development, deployment, and management of industrial applications. It acts as a central repository and access point for all FactoryTalk applications, streamlining workflows, and enabling multi-user collaboration.

Key Features of FactoryTalk Hub:

Cloud-Based Access: Accessible through a web browser, FactoryTalk Hub allows users to work from anywhere, sharing and deploying projects across distributed teams.

Centralized Repository: It stores and organizes project files, design resources, and applications, serving as a single source of truth for teams.

Collaboration and Version Control: Integrates with FactoryTalk Vault, allowing for version control, multi-user collaboration, and change tracking, compatible with industry tools like GitHub.

Integration with Design Tools: FactoryTalk Hub is compatible with several Rockwell design environments, including FactoryTalk Optix Studio and Studio 5000, enabling cloud-based design and management.

Scalability for Larger Enterprises: Enables enterprise-level collaboration, resource sharing, and secure data management for teams across different locations.

FactoryTalk Hub is ideal for organizations seeking enhanced collaboration and remote access, especially in scenarios where teams need to work on shared projects or manage assets across multiple sites.

OptixPanel terminals are dedicated hardware devices optimized to run FactoryTalk Optix software, providing an all-in-one solution for HMI deployment. These terminals come with pre-installed FactoryTalk Optix Runtime software and are designed specifically for industrial environments.

Key Features of OptixPanel:

Optimized for FactoryTalk Optix: Runs FactoryTalk Optix Runtime out of the box, requiring minimal setup and configuration.

Rugged Design: Built to withstand industrial conditions, with resistive and capacitive touchscreen options.

Multiple Display Sizes: Available in a range of screen sizes from 4.3” to 21.5”, meeting different application needs.

Pre-installed Runtime: Provides immediate FactoryTalk Optix functionality on a dedicated terminal, reducing installation complexity and ensuring quick deployment.

Cost-Effective for Small to Medium Deployments: Lower-cost alternative to PCs or industrial computers while maintaining reliability.

OptixPanel is ideal for users who want a pre-configured, dedicated HMI terminal for FactoryTalk Optix with reliable performance for machine-level control or visualization.

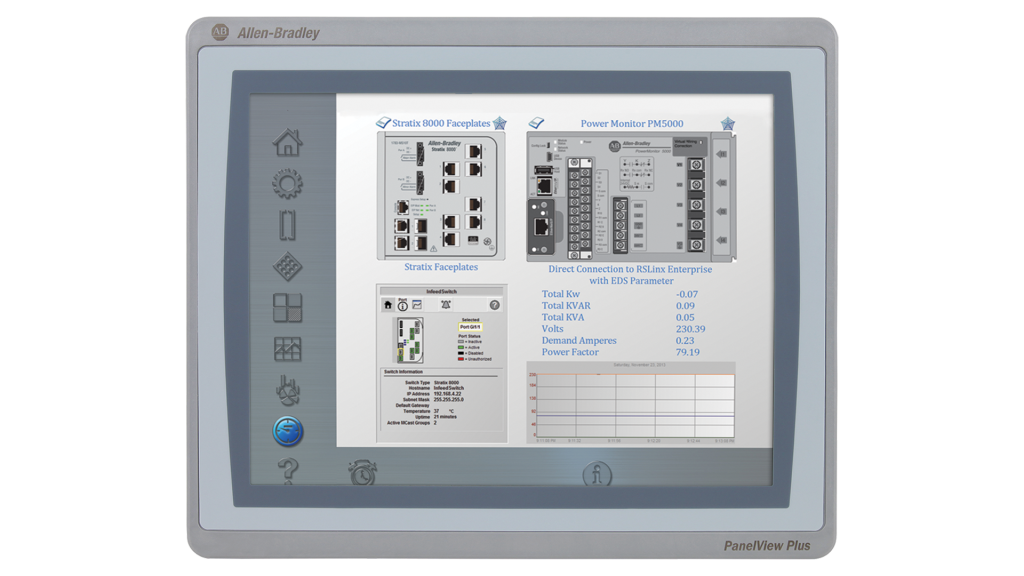

PanelView™ is Rockwell Automation’s established line of HMI terminals, designed to work primarily with FactoryTalk View ME (Machine Edition) and SE (Site Edition). PanelView terminals have a variety of models, from PanelView Plus to PanelView 5000, offering different levels of functionality, connectivity, and integration with Rockwell’s Logix control systems.

Key Features of PanelView:

FactoryTalk View Compatibility: Primarily runs FactoryTalk View ME or SE, optimized for tight integration with Logix controllers.

Wide Range of Models: Offers PanelView Plus, PanelView 5000, and PanelView 800, catering to different use cases from basic operator interfaces to advanced control and monitoring.

Robust Industrial Design: PanelView terminals are durable, designed to withstand harsh industrial environments.

Logix Integration: Premier integration with Allen-Bradley® Logix controllers offers ease of use for machine-level control and diagnostics.

Broad Industry Use: With multiple display options and form factors, PanelView is widely used across manufacturing, automation, and process control sectors.

PanelView is ideal for applications requiring close integration with Rockwell’s control systems, and it’s a reliable option for environments where FactoryTalk View ME or SE is the preferred HMI software.

Yes, FactoryTalk® Optix™ is designed to be an open and interoperable HMI platform, meaning it can work alongside other brands, including Siemens and Mitsubishi Electric, as long as they support the necessary protocols. FactoryTalk Optix supports a variety of standard communication protocols and third-party device drivers, allowing it to integrate with a range of control systems, including those from Siemens and Mitsubishi Electric.

Key Points for Using FactoryTalk Optix with Other Brands:

OPC UA Compatibility:

FactoryTalk Optix is built on OPC UA (Open Platform Communications Unified Architecture), a widely adopted, vendor-neutral protocol that facilitates communication between devices from different manufacturers. Many Siemens and Mitsubishi Electric devices also support OPC UA, which allows FactoryTalk Optix to exchange data with these systems.

MQTT Protocol for IoT:

For applications that involve IoT or IIoT, FactoryTalk Optix supports MQTT, a lightweight messaging protocol that works well with a variety of industrial devices. This allows FactoryTalk Optix to communicate effectively with systems that support MQTT for real-time data exchange.

Built-In Third-Party Drivers:

FactoryTalk Optix includes built-in drivers for a variety of third-party devices, including those from Siemens, Mitsubishi Electric, Modbus, CODESYS, and more. For instance, it includes drivers for Siemens S7TCP, Mitsubishi MELSEC, and other standard industrial protocols.

Integration and Extensibility:

With its open API and C# scripting capabilities, FactoryTalk Optix offers a high level of customization, making it easier to create application logic that integrates and manages data exchange with non-Rockwell devices. This makes it possible to adapt FactoryTalk Optix to fit into an existing infrastructure that includes other HMIs or control systems.

| Feature | FactoryTalk Optix | FactoryTalk Hub |

| Primary Function | HMI visualization and control | Cloud-based collaboration and centralized project management |

| Deployment | On-premises or cloud-accessible HMI applications | Cloud-based access through web browsers for design, storage, and deployment |

| Design Tool | FactoryTalk Optix Studio | Supports FactoryTalk Optix Studio and other FactoryTalk design tools |

| Integration Standards | OPC UA, MQTT, C# scripting for customization | Integrates with FactoryTalk Vault for version control and GitHub compatibility |

| Remote Capabilities | FactoryTalk Remote Access for remote monitoring and troubleshooting | Cloud-based design, multi-user collaboration, and centralized project access |

| Best Use Case | Real-time data visualization and HMI deployment | Collaborative project development and management across teams and sites |

| Feature | OptixPanel | PanelView |

| Primary Function | Dedicated HMI terminal for Optix | HMI terminal for FactoryTalk View |

| Software Compatibility | FactoryTalk Optix | FactoryTalk View ME/SE |

| Hardware Requirements | Pre-installed on OptixPanel hardware | Optimized for PanelView terminals |

| Integration Standards | Limited to FactoryTalk Optix | Tight integration with Logix systems |

| Deployment Flexibility | Pre-configured, standalone hardware | Wide range of models and sizes |

| Ideal Use Case | Quick, reliable HMI with Optix | Logix-integrated HMI applications |

In summary, FactoryTalk Optix focuses on visualization and control at the device level, while FactoryTalk Hub provides the collaborative infrastructure needed to manage and deploy projects effectively across an organization.

FactoryTalk® Optix™ offers a flexible, open architecture solution suited for diverse hardware and integration needs. OptixPanel provides a straightforward, all-in-one solution specifically for FactoryTalk Optix, ideal for dedicated machine-level interfaces. And lastly, PanelView terminals are designed for deep integration with Rockwell’s Logix systems and run FactoryTalk View, making them a trusted option for Rockwell-centric environments.

These platforms work together to streamline industrial automation design and deployment, from development to runtime.

While FactoryTalk® Optix™ can integrate with other brands, it may not offer the same level of tight integration as it does with Rockwell Automation controllers. For example, it may not have the same diagnostic capabilities or access to proprietary features specific to Siemens or Mitsubishi HMIs and controllers.

FactoryTalk® Optix™ offers unparalleled flexibility and scalability, making it the perfect HMI solution for both greenfield and brownfield projects. Whether your goal is to build a future-proof industrial operation from the ground up or to seamlessly upgrade existing systems, FactoryTalk® Optix™ delivers the tools and capabilities needed to optimize industrial processes.

If you're looking to integrate this powerful platform into your operations, Ultech Engineering is here to help.