The momentum is unmistakable as we move into the final stretch toward Oil and Gas Asia (OGA) 2025. In just five days, Kuala Lumpur will once again become the heart of the region’s energy innovation, bringing together the best of engineering, technology, and partnership. For Ultech Engineering, this event marks more than just another exhibition — it is a celebration of growth, strategy, and collaboration. Among our most significant collaborations is the one with SPT Maju Sdn Bhd, a PETRONAS-registered company working under the Ultech Engineering umbrella to supply top-tier electrical and instrumentation components to the oil and gas industry.

This partnership isn’t just about supplying parts — it’s about building a sustainable, intelligent ecosystem that addresses the increasingly complex challenges of Malaysia’s energy landscape. Together, we represent a cohesive and scalable approach to oil and gas engineering, combining technical expertise, certified products, and responsive customer service.

SPT Maju has been officially recognized through a strategic partnership with Ultech Engineering, marking a pivotal moment in both companies’ growth within Malaysia’s oil and gas sector. This collaboration combines Ultech’s automation and engineering expertise with SPT Maju’s robust onshore and offshore electrical capabilities, forming a powerful alliance that enhances market reach, accelerates project execution, and improves operational agility.

Positioned as the appointed agent of Ultech Engineering, authorised system integrator (SI) for Mitsubishi Electric, authorised distributor for Weidmuller, and sole distributor in Malaysia for Cabex. SPT Maju now plays a critical role in driving industrial innovation and sustainability. By combining high-quality manpower, certified engineering design, and field execution, this partnership is actively shaping the future of oil and gas projects—and further demonstrating the bold new chapter both companies are entering together.

In line with its growing capabilities, SPT Maju has also strengthened its credibility through several key industry accreditations, including registration with the Construction Industry Development Board (CIDB) for recognized construction and engineering works, the Ministry of Finance (MOF) as an approved government supplier, and licensing as an Electrical Installation Contractor (EIC) — enabling the company to carry out certified electrical work in critical infrastructure projects. Additionally, SPT Maju now holds a sixth PETRONAS SWEC code, further expanding its ability to participate in a wider range of oil and gas projects under PETRONAS procurement.

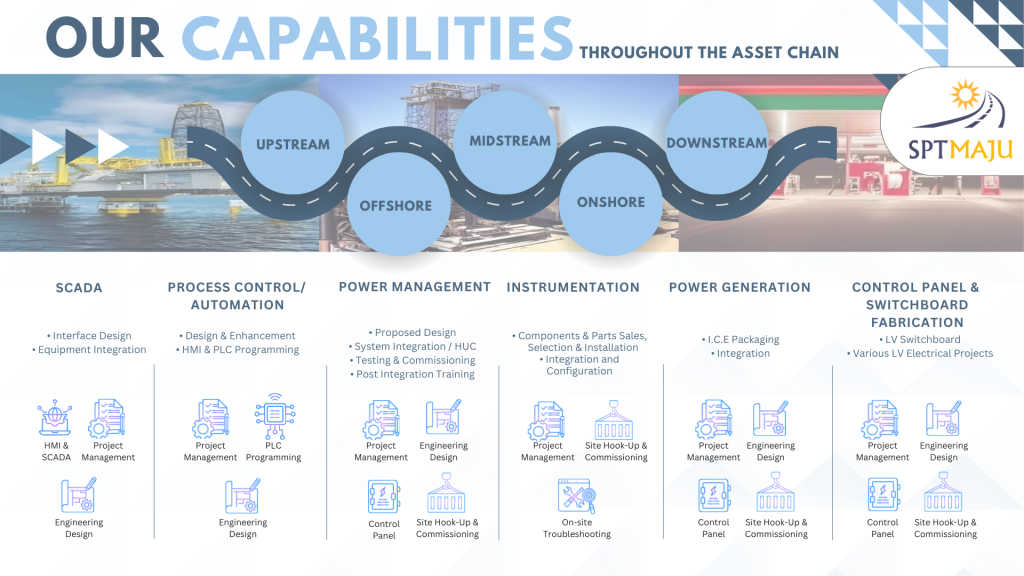

In a sector as complex and mission-critical as oil and gas, successful operations rely on seamless integration throughout the asset chain — from upstream exploration and offshore platforms to midstream processing, onshore terminals, and downstream distribution. SPT Maju plays a strategic role in enabling this integration by delivering engineering capabilities and component solutions tailored for each segment of the industry.

Their presence isn’t limited to a specific project phase —SPT Maju is capable of supporting projects across the entire supply chain, working hand in hand with their principal partner, Ultech Engineering, such as the entire oil and gas lifecycle, providing design, engineering, installation, and commissioning expertise across every key discipline.

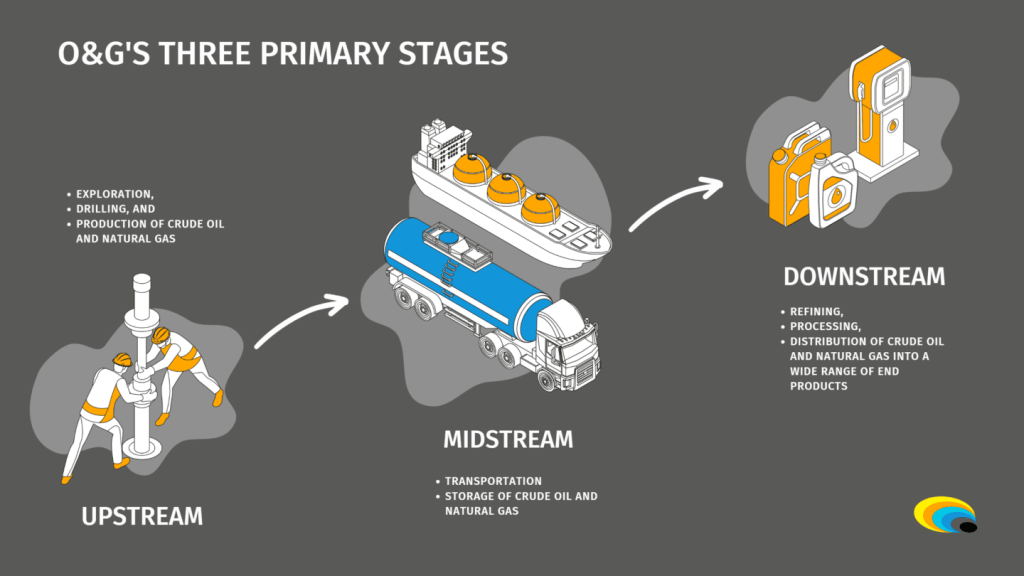

For upstream operations, SPT Maju provides highly specialised support where efficiency, safety, and environmental compliance are paramount. Their engineering services begin with SCADA systems, where they handle interface design and equipment integration to create visual, real-time process control environments. Through process control and automation, they offer HMI and PLC programming tailored to exploration needs. Additionally, SPT Maju ensures reliable power management, integrating systems and executing hook-up and commissioning for generators, pumps, and compressors — essential for upstream success. This segment is also known as exploration and production (E&P). It includes activities like identifying potential reserves, drilling wells, and extracting crude oil and natural gas.

In midstream activities such as processing plants and transmission stations, SPT Maju provides instrumentation solutions, including component selection, integration, and field calibration. Their support extends to power generation, where they package Internal Combustion Engine (I.C.E) systems and integrate them with on-site infrastructure for continuous energy supply. Their custom control panels and switchboards are fabricated and installed according to both local and IEC requirements, ensuring midstream operations remain uninterrupted. This segment involves the transportation and storage of crude oil and natural gas. It includes pipelines, tankers, storage facilities, and other infrastructure needed to move these resources from production sites to refineries.

SPT Maju extends its engineering value to downstream activities, including fuel terminals, depots, and station networks. They implement low-voltage electrical projects that cover site-wide electrical infrastructure, automation panels, and protective systems. These solutions are designed to optimize energy usage, reduce risk, and improve operational visibility. Their downstream work is built to be scalable and compliant with safety and commercial regulations. This segment focuses on processing crude oil and natural gas into finished products like gasoline, diesel, jet fuel, and various petrochemicals. It also includes the marketing and distribution of these products to consumers.

Operating in offshore environments requires precision and resilience. SPT Maju brings both through its control and monitoring systems, including HMI/SCADA, PLC programming, and power infrastructure solutions. They play a vital role in offshore system integration, from engineering design and panel fabrication to final testing and commissioning. With the added complexity of marine operations, SPT Maju ensures robust execution that aligns with safety standards and project schedules.

A strong example of the type of offshore project that SPT Maju is capable of executing in collaboration with its principal partner, Ultech Engineering, is the recent upgrade completed on the Seligi Platform operated by ENQUEST. While the project was led by Ultech Engineering, it highlights the scale and complexity of work that SPT Maju is well-positioned to support, particularly in hazardous zone control systems and critical offshore infrastructure.

The Seligi Platform, operated by ENQUEST, underwent a critical upgrade project titled "Provision of Hazardous Zone NFPA20 Controller and Secondary Starting System Upgrading." The project addressed major issues with the existing firewater pump control panel, which was in poor condition, heavily modified, and lacking proper documentation. Previously, the system relied solely on a single pneumatic starter, which proved to be unreliable. To enhance reliability and operational safety, a secondary hydraulic starter was introduced as a backup, providing a dual-starting capability to ensure emergency readiness.

The upgraded control panel, certified for Zone 2 hazardous areas, was successfully handed over in October 2023. Significant safety improvements were made, including pressure monitoring for the pneumatic starting vessel and the ability for operators to manually switch the primary starter via an HMI if faults are detected. Furthermore, the system can automatically switch to hydraulic start if low pneumatic pressure is detected, ensuring uninterrupted pump operation during emergencies.

The control and interface system was modernized with an integrated HMI that includes alarm logging, active alarm views, pump status overviews, and real-time analog signal monitoring. High-level communication protocols were also implemented, allowing seamless integration with the centralized control system for advanced diagnostics and remote monitoring. This upgrade not only brought the system in line with NFPA20 standards but also significantly enhanced the platform’s emergency response capability and long-term maintainability.

Onshore operations benefit from SPT Maju’s comprehensive engineering services, which span low-voltage switchboard design, power distribution, and site-level control. Their expertise covers both new and retrofitted facilities, ensuring that electrical systems meet industrial performance standards. With on-site hook-up, testing, and commissioning, SPT Maju ensures that critical systems come online smoothly and operate with high reliability.

A notable example of SPT Maju’s downstream contribution is their project with Malaysia LNG Sdn. Bhd., where they supplied and integrated an Outdoor Instrument Interface Panel. This panel plays a critical role in ensuring the accurate and efficient operation of downstream instrumentation systems. It was delivered with full certification, complying with the highest industry standards, and was used to replace existing panels, enhancing both functionality and compliance. The solution also supports seamless integration and dependable interfacing with other systems, making it ideal for both new installations and system upgrades.

Ultech Engineering’s presence at OGA 2025 will highlight our core capabilities that continue to evolve with the needs of the oil and gas sector. Our portfolio covers four critical pillars:

Process control is the heart of industrial automation. Our services in this area include the installation and maintenance of firewater pump systems — a critical safety feature in oil and gas installations. Whether on offshore rigs or downstream facilities, firewater pumps must be ready to operate immediately. Any delay can result in catastrophic consequences.

Ultech Engineering also offers advanced PLC (Programmable Logic Controller) troubleshooting and maintenance services. PLCs are the nerve center of automated processes. A minor fault in a PLC system can bring entire production lines to a halt. Our engineers are trained to diagnose faults swiftly and perform preventive maintenance to minimize unplanned downtime.

We work across a variety of platforms and systems, ensuring compatibility and integration with existing infrastructure. Whether it’s routine PLC inspections, software logic updates, or full-scale revamps, our expertise ensures optimal process continuity and plant safety.

Power management in the oil and gas sector demands stability, resilience, and precision. Ultech Engineering specializes in the integration and control of Emergency Diesel Generators (EDGs) using advanced DEIF systems, such as the iE350 and AGC150.

These systems ensure that power remains uninterrupted even during emergencies or power grid failures. Our engineers configure, program, and test these controllers according to project specifications — a critical service in offshore facilities, refineries, and remote platforms where power loss can be dangerous.

Beyond the technology, what sets us apart is our ability to integrate these power systems into wider plant operations — connecting them with PLCs, HMIs (Human-Machine Interfaces), SCADA systems, and control rooms for centralized monitoring and response.

Instrumentation lies at the intersection of precision, performance, and safety. At Ultech Engineering, we offer instrumentation services that utilize industry-grade products such as Cabex cable glands and Weidmüller terminal blocks and connectors.

Cable glands are often overlooked, but they serve as the first line of defense against dust, moisture, gas ingress, and mechanical strain. SPT Cabex glands are flameproof and certified to meet Ex standards, making them ideal for use in hazardous zones. With their superior sealing and clamping technology, they ensure long-term operational safety.

Weidmüller products, meanwhile, provide reliable electrical connections in control cabinets, offering quick installation, vibration resistance, and modular expandability. These components are essential in ensuring signal integrity across analog and digital instrumentation systems, including pressure transmitters, flow meters, and level sensors.

Our hands-on experience ensures that every instrument installed performs to its full potential, accurately reflecting the real-time conditions of your process environment.

A significant portion of Ultech Engineering’s operations lies in the custom design and fabrication of control panels, switchboards, and distribution boards (DBs). These systems are essential for operational command, signal routing, and energy distribution within a PLC. Whether for EDG switchboards or DBs for building management, every panel fabricated at our facility undergoes stringent quality checks from component layout planning and thermal analysis to wiring and final testing.

Our control panels and switchboards are designed for optimal performance, featuring clean wiring, intuitive layouts, and long-term serviceability. Whether managing EDG systems or integrating automation and distribution boards, we tailor each solution to project-specific requirements, using either in-house designs or Rockwell Automation’s CUBIC Modular MCC Systems. It’s more than just control; it’s about delivering reliable systems that engineers and operators can depend on daily.

The countdown to OGA 2025 is more than just a marketing milestone. It represents a renewed commitment to technological advancement, strategic collaboration, and sustainable growth. For Ultech Engineering, this year’s participation underscores the power of partnerships, particularly our ongoing collaboration with SPT Maju.

We will be showcasing:

Visitors to our booth will not only witness the integration of hardware and engineering but will also engage with the very people driving these solutions — our engineers and technical advisors.

The countdown is almost over, but our journey is just beginning.

Join Ultech Engineering and SPT Maju at OGA 2025 and experience firsthand how collaboration, capability, and commitment are redefining Malaysia’s oil and gas engineering solutions.

🔹 Booth No: 2612

🔹 Date: 2-4 September 2025

🔹 Location: Kuala Lumpur Convention Centre Hall 2 (KLCC)

Let’s power the future — together.