The palm oil industry is a cornerstone of Malaysia’s economy, requiring continuous advancements in automation to enhance productivity, ensure operational safety, and optimize energy consumption. Ultech Engineering, in collaboration with SPT Maju Sdn. Bhd., has played a crucial role in modernizing palm oil mills by implementing innovative control and monitoring solutions. As the appointed sole agent and distributor of Ultech Engineering services, SPT Maju Sdn. Bhd. has helped transform palm oil milling operations through automation and smart control systems. This article provides a detailed look at key projects executed across different mills, illustrating their impact on efficiency and sustainability.

As an authorized brand partner of Mitsubishi Electric Factory Automation in Malaysia, Ultech Engineering is at the forefront of providing cutting-edge automation solutions. Mitsubishi Electric is renowned globally for its high-performance PLCs, HMIs, inverters, and servo systems, offering reliability and precision for industrial applications. Meanwhile, SPT Maju Sdn. Bhd. also serves as an authorized system integrator, ensuring seamless implementation and integration of Mitsubishi Electric technologies into palm oil mill operations. As such, many of the automation solutions featured in this article—including PLCs, HMIs, and control systems—are powered by Mitsubishi Electric’s advanced industrial automation technology, delivering increased efficiency and operational excellence.

This article provides a detailed look at key projects executed across different mills, illustrating their impact on efficiency and sustainability.

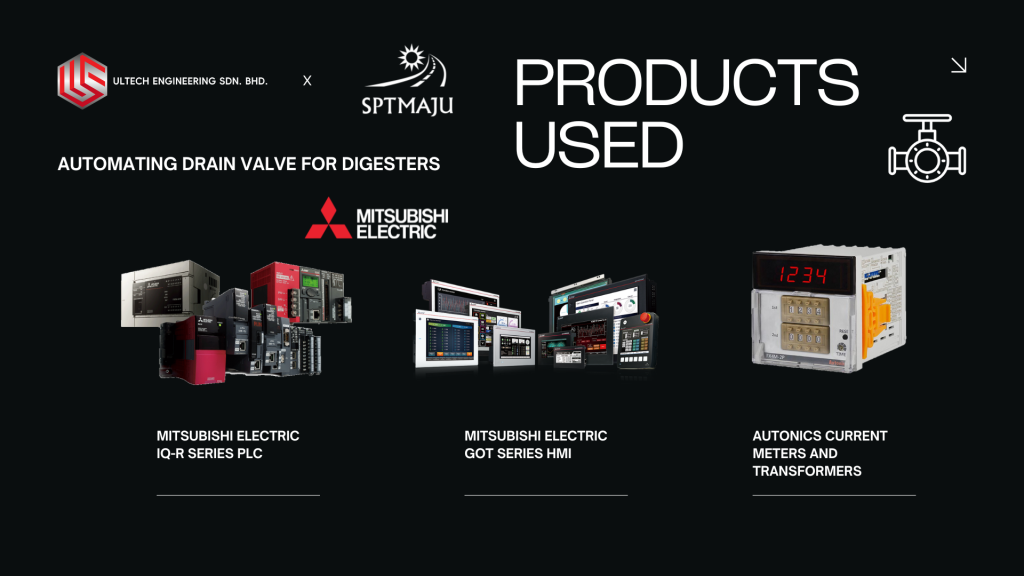

The digester is a critical component in the palm oil extraction process, acting as a big blender that rotate and mesh up the fruit within its central shaft. Previously, operators at mills such as one of our projects in Niah in 2020 manually controlled drain valves based on visual inspection of the digester’s running current, leading to inefficiencies and inconsistencies.

To address this, Ultech Engineering implemented an automated system utilizing Mitsubishi Electric iQ-R Series PLC, Mitsubishi Electric GOT Series HMI, Autonics Current Meters, and Autonics Current Transformers to measure and monitor running currents of the digester. An electric valve actuator was installed to open and close the drain valve automatically based on preset setpoints on the current meter readings. This resulted in precise control, reducing human error and ensuring optimal drainage. The automation not only improved efficiency in palm oil recovery but also minimized losses and eliminated the need for constant manual supervision.

The digester plays a vital role in the palm oil extraction process by softening the fruit before pressing. Ensuring proper drainage control in the digester is essential to maintain process efficiency and prevent clogging or excessive moisture content in the extracted oil.

Ultech Engineering designed and integrated an automated drain valve control system to regulate the discharge of excess water and solid residues. The system features:

Fresh Fruit Bunches (FFB) play a crucial role in the milling process, requiring efficient transport systems to avoid delays. Previously, the palm oil mill project commissioning in 2019, located in Niah, required four operators to manually move two carriages from the input line to another line for sterilization. The outdated system led to inefficiencies and high labor costs.

Ultech Engineering introduced a modernized control system utilizing Mitsubishi Q-Series PLCs and Mitsubishi GOT2000 HMIs for operator monitoring and control, combined with Omron E3Z-T61 Photoelectric Sensors for precise carriage positioning. The new system allowed a single operator to control two carriages from a centralized platform, significantly reducing manpower while improving efficiency. The automated photoelectric sensors ensured precise positioning, accelerating the process while maintaining consistency. This resulted in labor cost savings, improved productivity, and enhanced workplace safety by minimizing manual handling risks.

Fresh Fruit Bunches (FFB) are transported within the mill using a carriage system. Efficient movement of FFB ensures a smooth production process, reducing bottlenecks and increasing throughput.

Ultech Engineering modernized the FFB Transfer Carriage Control System with:

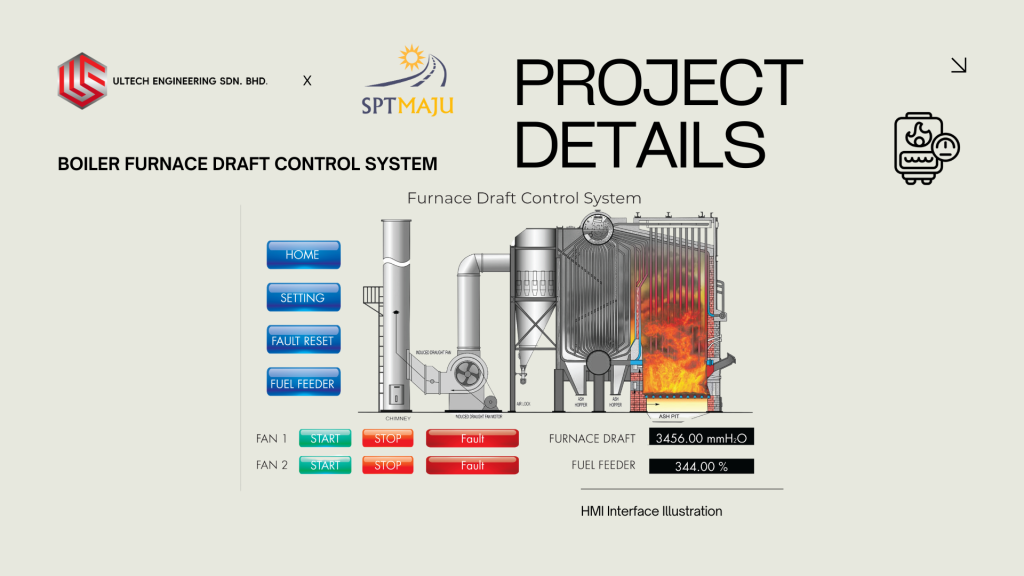

Boilers are a fundamental part of palm oil milling, generating steam for various processes. Effective draft control is essential for maintaining optimal combustion and minimizing energy waste. Prior to the automation project implementation in 2021, another palm oil mill project in Miri used resistance-type starter controls that lacked precision, requiring oversized generators to handle high starting amperage. This inefficient setup increased operational costs and energy consumption.

Ultech Engineering introduced an automated Boiler Furnace Draft Control System, integrating a Mitsubishi Electric iQ-R Series PLC for precise automation with built-in PID logic to control the damper that modulates air intake to maintain the furnace draft at a vacuum condition and Mitsubishi Electric GOT Simple Series HMI for user-friendly operation. The system utilized real-time sensors to optimize airflow and improve combustion efficiency. By automating ID fan speed control using a Mitsubishi Electric FREQROL Inverter, the mill achieved significant power savings and reduced generator surging during heavy motor start-ups. The implementation led to enhanced boiler efficiency, lower emissions, and cost savings by optimizing fuel usage.

Boilers are a crucial component in palm oil mills, generating steam for various processes. Controlling the furnace draft is essential to ensure efficient combustion and prevent excess emissions.

Ultech Engineering developed an automated Boiler Furnace Draft Control System featuring:

Fuel-feeding accuracy is critical for maintaining combustion efficiency in palm oil mills. At our palm oil mill project in Tatau, operators previously had to manually monitor furnace conditions and operate the fuel feeder gate, a process prone to human error and inconsistencies.

With the automation project in 2022, Ultech Engineering implemented an automated Cylinder Valve Control Monitoring System, integrating a Mitsubishi Electric iQ-R Series PLC for real-time control and the Mitsubishi Electric GOT Simple Series HMI for seamless user interaction that controls the hydraulic mechanism that precisely regulates the opening and closing of the fuel feeder gate while incorporating client-provided Pneumatic Cylinder with a Proximity Sensor. This system minimized human intervention, ensuring accurate and consistent fuel feeding. The automation reduced operational downtime, improved combustion efficiency, and enhanced overall mill performance. By eliminating manual errors, the mill experienced improved safety conditions, optimized energy consumption, and a reduction in labor dependency.

Cylinder valves control the flow of hydraulic and pneumatic power in palm oil mill machinery. Proper monitoring and control of these valves are essential to maintain process stability and prevent mechanical failures.

Ultech Engineering introduced an advanced Cylinder Valve Control Monitoring System, including:

Through these transformative projects, Ultech Engineering and SPT Maju Sdn. Bhd. have played a pivotal role in enhancing automation and efficiency in the palm oil industry. By integrating smart control systems, mills have achieved significant cost savings, improved productivity, and reduced environmental impact. From automated drain valve systems to energy-efficient boiler draft control and precise FFB transfer solutions, Ultech Engineering continues to drive innovation in the sector. As palm oil mills strive for greater efficiency and sustainability, these automation solutions will remain crucial in shaping the industry's future.

If you are looking to optimize your palm oil mill operations, reach out to Ultech Engineering and SPT Maju Sdn. Bhd. today to explore how our advanced engineering solutions can enhance your business.

As we continue to innovate, we look forward to bringing even more advanced engineering solutions to the industry. If you are interested in optimizing your palm oil mill operations, contact us today to explore how our expertise can drive your business forward.