In the expansive landscape of the oilfield, where the extraction of crude oil is a primary focus, another critical element comes into play - produced water. This naturally occurring byproduct, often overlooked, demands careful management to ensure environmental compliance and sustainable operations within the industry. In this article, we will be diving deeper into the case study of Rockwell Automation Flexible Control, Versatile Water Treatment and how their PlantPAx Distributed Control System solve the issue.

Water, as it turns out, is not just essential for life but also for the very processes that drive oil extraction, such as drilling and fracking. "Water is a primary ingredient in 'drilling mud'," explains John Clay, CEO of Endpoint Industrial Controls. "It helps equalize pressure and stabilize exposed rocks during the well-drilling process. Additionally, water is used to create fractures, enhancing the flow of hydrocarbons."

However, the challenge arises with the nature of produced water. Highly brackish and untreated, it is unsuitable for direct use in drilling and fracking operations. Traditionally, most of this produced water found its way to highly regulated saltwater disposal (SWD) wells, while oil companies relied on separate water sources for their production needs.

Yet, in recent years, a shift has been underway. Thanks to advancements in water treatment technologies, there's a growing trend towards recycling produced water. One company, in particular, has been at the forefront of this movement, paving the way for more sustainable practices in the oilfield. They turned to Endpoint for an agile control system that could complement their innovative water treatment and recycling technologies.

Endpoint Industrial Controls specializes in providing turnkey automation and control solutions across various industries, including oil and gas. Headquartered in Loveland, Colorado, the company is part of the Rockwell Automation® PartnerNetwork™ program.

Established in 2013, Endpoint's client operates numerous geographically dispersed water recycling facilities and pipelines across the oil-rich Permian Basin in West Texas and New Mexico. Collectively, these facilities manage a staggering 1.2 million barrels of produced water daily.

"The company's operations include both permanent facilities and mobile units," Clay elaborates. "These mobile systems are set up for varying durations, from a couple of months to several years, before being rotated to another site."

Central to the water treatment system is Dissolved Air Flotation (DAF) technology. The influent water stream undergoes treatment in DAF vessels, where a mix of chemicals, including coagulants, flocculants, and oxidants, is introduced. A pressurized airstream creates micro-bubbles in the solution.

Lighter particles in the water attach to these bubbles and rise to the surface, while heavier particles settle at the bottom. This sludge, primarily composed of hydrocarbons, chemicals, and solids, is then removed. The treated effluent, now purified, is pumped to a clear water well where it undergoes further testing for clarity before being stored and reused in fracking operations.

From a control standpoint, the system presents two significant challenges. "Firstly, each site is unique, and we may be dealing with varying numbers of DAF units," Clay explains. "Secondly, the system must be responsive enough to handle the substantial volume of water - up to 3000 gallons per minute, or 100,000 barrels per day for each DAF on site."

In response to these challenges, Endpoint built its control solution around the versatile PlantPAx distributed control system (DCS) from Rockwell Automation. "Given the diverse instrumentation we encounter from site to site, PlantPAx Distributed Control System offered the flexibility we needed," says Clay. "We developed a program that allows for high configurability within a condensed timeline."

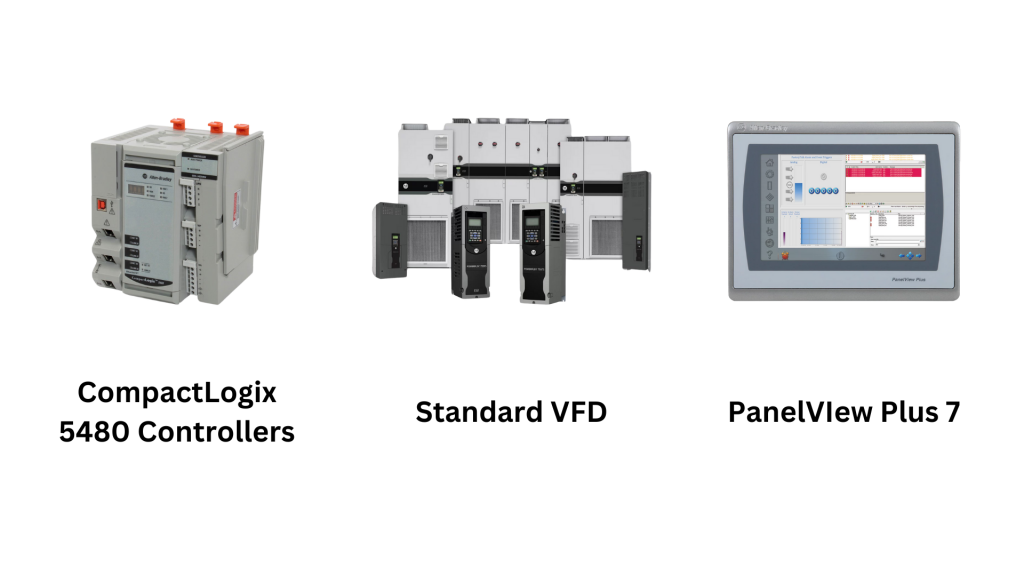

Endpoint typically completes the commissioning of a new site within one to four hours, ensuring minimal disruptions to operations. To meet the speed requirements, the skidded solution relies on Allen-Bradley® CompactLogix™ controllers, PowerFlex® AC drives for pump control, and PanelView™ HMIs. Alongside providing on-site monitoring capabilities, Endpoint integrates SCADA systems for comprehensive reporting at the company's headquarters.

Collaboration with the client is key, especially as skids are relocated and repurposed. "Our client can make most control system changes through the HMI interface," Clay notes. "However, should they require assistance, we can often handle programming changes remotely."

Yet, the challenges don't end with complex control systems. Many of these water treatment sites are situated in rugged, remote locations with minimal network connectivity. "Most sites lack network coverage or mobile phone service," Clay adds. "Instead, we rely on a low-orbit satellite service for the necessary access to manage end-to-end integration."

The true test of this innovative water treatment system came in December 2022, following a pipeline oil spill near Mill Creek, Kansas. The ruptured pipeline released over 500,000 gallons of crude oil into the environment, prompting authorities to call upon Endpoint's client for assistance in remediation efforts.

Swiftly repurposing one of their existing skids, the client's surface water treatment system, based on DAF technology, sprang into action. According to the EPA, the system effectively treated and discharged up to 4.5 million gallons of water per day during the remediation efforts, totalling over 35 million gallons. In this critical moment, Endpoint's client played a pivotal role in mitigating the environmental impact of the spill.

As the oil and gas industry continues to navigate the delicate balance between production demands and environmental responsibility, innovative solutions like these offer a beacon of hope. By embracing cutting-edge technologies and collaborative partnerships, the path to a more sustainable future in the oilfield becomes clearer, one drop of water at a time.

The Rockwell PlantPAx Distributed Control System (DCS) is an industrial automation system designed to monitor and control processes within various industries. It provides a centralized platform for managing process control, data acquisition, visualization, and reporting. The system is known for its scalability, integration of control functions, open architecture, advanced functionality, and safety features.

In terms of sustainability, the Rockwell PlantPAx Distributed Control System offers tools and features to help industries optimize their operations for environmental efficiency. This includes energy management tools for monitoring and reducing energy consumption, resource efficiency features to minimize waste and optimize production output, emission monitoring capabilities to stay compliant with regulations and reduce carbon footprint, predictive maintenance to prevent equipment failures and reduce resource-intensive repairs, and remote monitoring for efficient use of resources and reduced commuting emissions.

The latest process controllers in the Logix family enhance capabilities with advanced processing power and increased capacity, aiming to simplify PlantPAx Distributed Control System architectures. This downsizing not only decreases the system’s total cost of ownership but also extends throughout its lifespan.

Equipped with built-in native process instructions, the controllers empower project teams to implement control strategies that promote consistency across individual projects or multiple-site installations.

Development teams will efficiency gains in configuring instruments, alarms, and diagnostics elements within the system. Operators will also benefit from improved access to underlying control logic in a secure environment.

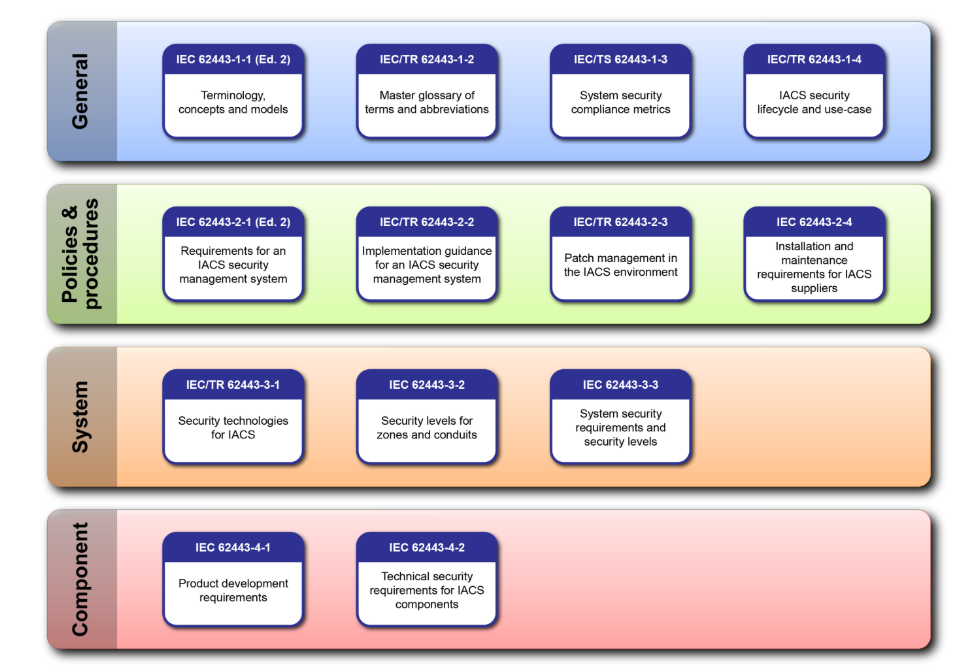

To address potential risks, the PlantPAx Distributed Control System architectures hold TUV certification according to the international standard ISA-99/IEC 62443-3-3. This certification offers guidance on establishing a secure electronic system.

The PlantPAx 5.0 release introduces purpose-built frameworks facilitating seamless integration of real-time and historical data from the DCS into reporting and analytical tools. This enables enhanced functionalities like Augmented Reality experiences and simple integration with scalable analytics packages.

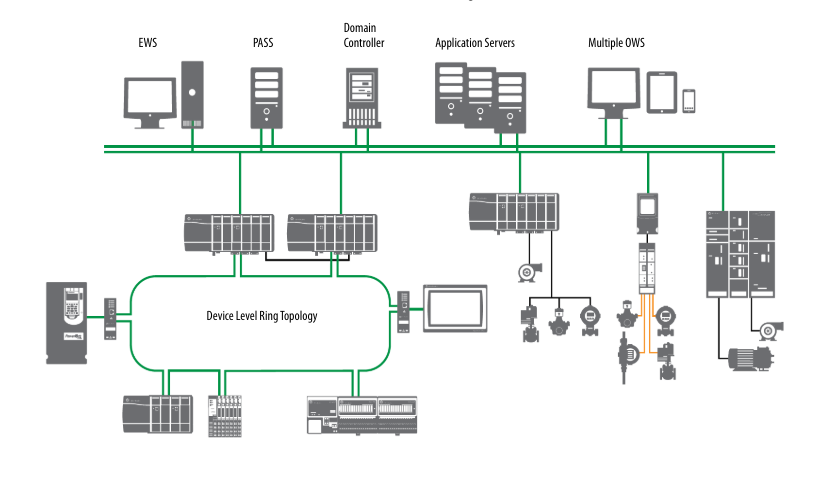

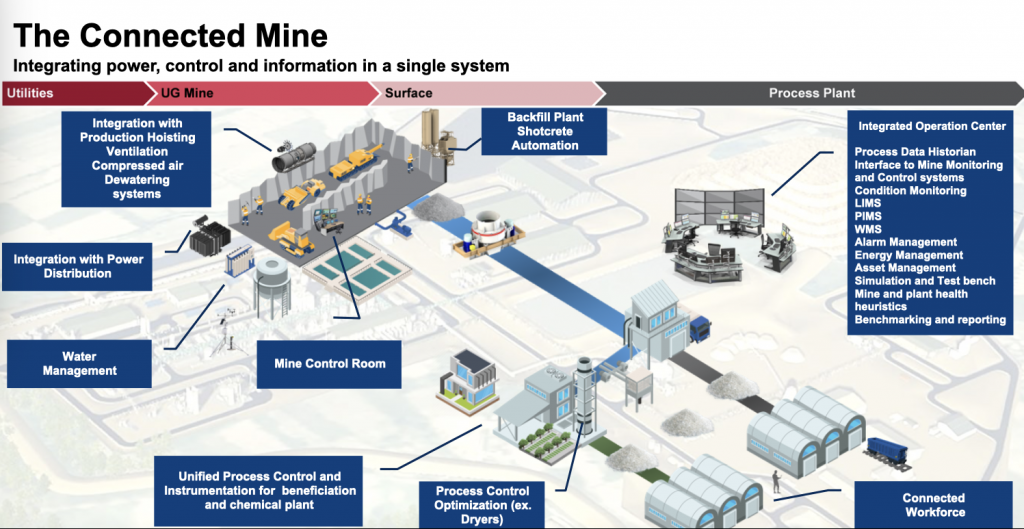

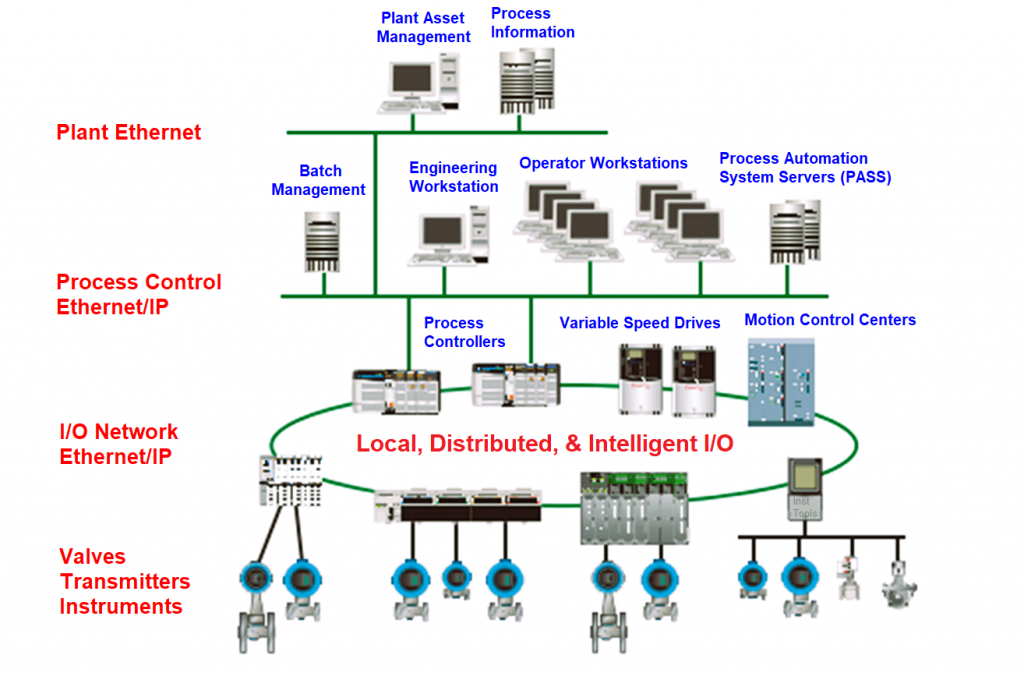

The PlantPAx Distributed Control System employs a unified automation platform to seamlessly link critical areas within your plant. This modern PlantPAx Distributed Control System (DCS) consolidates process, discrete, power, information, and safety controls into a single, plant-wide infrastructure. The advantages include standardized platforms, smooth data flow, simplified management, and reduced overall ownership costs.

The PlantPAx Distributed Control System offers a diverse range of architecture options to enhance flexibility. This allows the same platform to be deployed for single stations or expansive distributed architectures. The result is effortless integration without data duplication, quicker time-to-market, and adaptable system capabilities such as Human Machine Interface (HMI), batch management, and data collection.

Built on open communication standards, the modern PlantPAx Distributed Control System utilizes EtherNet/IP as its core framework. Consequently, real-time information becomes readily accessible throughout the organization, empowering better business decision-making. By leveraging virtualization and mobility, businesses can make informed choices, foster IT/OT convergence with Commercial Off-The-Shelf (COTS) hardware, achieve up to 10% energy reduction, and establish a methodical defence-in-depth strategy to safeguard information.

The PlantPAx Distributed Control System provides the flexibility to select the optimal implementation and support team tailored to your requirements. Whether it's the delivery of the system alongside other top-tier solutions or the involvement of your local process system integrator with whom you have an established partnership, the choice is yours for ongoing support and implementation.

The article sheds light on the critical role of water management in the oilfield industry, particularly highlighting the innovative solutions offered by Rockwell Automation's PlantPAx Distributed Control System. As the oil and gas sector faces the dual challenge of maintaining production efficiency while adhering to environmental sustainability, the PlantPAx Distributed Control System emerges as a key tool for achieving these objectives.

By enabling precise control and monitoring of water treatment processes, the PlantPAx DCS contributes significantly to the industry's move towards sustainable practices. The system's flexibility, scalability, and advanced functionalities empower companies like Endpoint Industrial Controls to efficiently manage the complex task of recycling produced water.

Endpoint's case study in the Permian Basin showcases the real-world impact of these technologies. With the ability to treat millions of gallons of water per day, the PlantPAx Distributed Control System plays a pivotal role in mitigating environmental risks, such as the recent oil spill near Mill Creek, Kansas. This success not only demonstrates the system's effectiveness but also highlights the crucial role of collaboration between technology providers and industry players. Ultech Engineering, in partnership with Rockwell Automation, can leverage this case study to learn and potentially implement similar solutions in the future. This could serve as a significant stepping stone for Ultech Engineering to explore and innovate with new technologies.

As Ultech Engineering continues to embrace cutting-edge technologies and foster collaborative partnerships, the vision of a greener, more sustainable oilfield industry becomes increasingly attainable. In this pursuit, Ultech Engineering can delve deeper into the PlantPAx Distributed Control System, which stands as a beacon of hope for the oil and gas sector, offering a clear path towards a more environmentally friendly and sustainable future.