Rockwell Automation stands at the forefront as the industrial landscape continues to evolve, driving innovation with its PowerFlex® drives. The company's commitment aims to enhance productivity through integrated control and information systems. This article delves into the key features and technological advancements of PowerFlex® drives, highlighting how they cater to modern industry demands.

With around 29,000 employees and fiscal 2023 sales of approximately $9 billion, Rockwell Automation operates in over 100 countries. The company emphasizes above-market growth, productivity, and intellectual capital to create value for its stakeholders. Its global support infrastructure includes remote support centers across major regions, ensuring high customer satisfaction and rapid response times.

PowerFlex® Drives with TotalFORCE® Technology offer total control over your motors with optimized velocity and torque control for multiple motor types and adaptive control capabilities. They provide total visibility into the health of drive components, maximizing uptime with scheduled maintenance tailored to your usage and environment. Additionally, they deliver total command over your drives through a unified platform, featuring the same control architecture and network interface for both Low-Voltage and Medium-Voltage drives, resulting in a simplified user experience.

The Medium Voltage Drive Portfolio for the Powerflex 6000T features premier integration with the Studio 5000 Environment, a simple power structure, safe torque-off and arc-resistant design, and virtually unlimited cable lengths. It includes air-cooled models ranging from 200 to 8000 Hp / 150 to 6000 kW, liquid-cooled models from 1250 to 9000 Hp / 930 to 6700 kW, and ratings of 2.3, 3.3, 4.16, 6.6, and 11 kV, with configurations including direct-to-drive, AFE rectifier, and 18, 36, and 54-pulse rectifiers.

The PowerFlex series meets and complies with the IEEE 519 Low Harmonic Standard through its built-in AFE or transformer, ensuring minimal harmonic distortion in electrical systems.

IEEE 519 is a standard that addresses harmonic distortion limits in electrical power systems, aiming to reduce interference and maintain power quality by setting limits on the levels of harmonic currents and voltages that can be present.

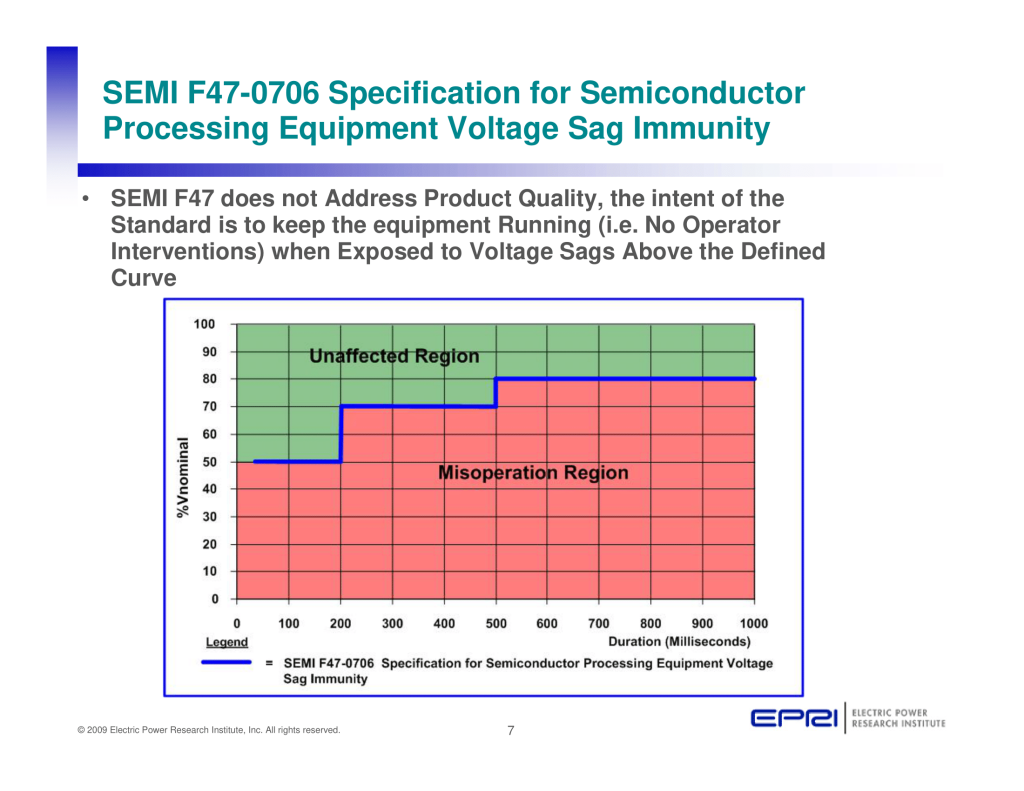

The PowerFlex 755T is certified SEMI F47 to withstand voltage sag power quality events and is equipped with a Power Loss ride-through feature, allowing the drive to continue operating during short-term power losses.

SEMI F47 is a standard developed by the Semiconductor Equipment and Materials International (SEMI) organization, specifying the equipment's requirements to handle voltage sags and dips in semiconductor manufacturing environments. It aims to ensure that equipment can tolerate brief interruptions in power without malfunctioning or causing damage, thus maintaining reliability and reducing downtime.

PowerFlex can be equipped with additional machine learning AI algorithms to detect anomalies in assets such as pumps, fans, and motors.

The PF755T is the first standard VSD in the world to utilize extra protection for corrosive gas environments, providing the highest GX/CX level of corrosive protection for your device.

Using Rockwell's patented technology, PowerFlex can predict its component lifetime, ensuring high availability and efficiency through advanced predictive maintenance.

PowerFlex is designed for high serviceability. Its modular design allows for easy maintenance and reduces mean time to repair (MTTR).

The PF755T includes all the premier integration features of the previous family, including Automatic Device Configuration (ADC), which ensures plug-and-play replacement in VSD systems.

Combining FactoryTalk® Analytics™ GuardianAI™ software with PowerFlex 755TL, TR, and TM VFDs provides an unprecedented view into the health of your plant assets. This integration continuously monitors variable frequency drives (VFDs) and plant assets, alerting you to potential issues before they become critical.

This predictive maintenance approach provides actionable insights that can reduce risk, optimize maintenance plans, and ensure more reliable application operation. By identifying problems early, you gain valuable time to plan and act, avoiding costly downtime and unplanned repairs.

Integrating FactoryTalk® Analytics™ GuardianAI™ with PowerFlex® 755T-Series Variable Frequency Drives (VFDs) marks a transformative leap in industrial automation and maintenance. This advanced solution facilitates a shift from traditional reactive and scheduled maintenance approaches to a sophisticated predictive maintenance model. It enhances operational reliability and efficiency by offering continuous monitoring, real-time alerts, and actionable insights.

The synergy between advanced analytics and robust VFD technology mitigates risks, optimizes maintenance strategies, and ensures maximum uptime and performance. As industrial automation evolves, this innovative approach will be pivotal in shaping the future of industrial maintenance, driving operational excellence, and achieving sustained success.