06

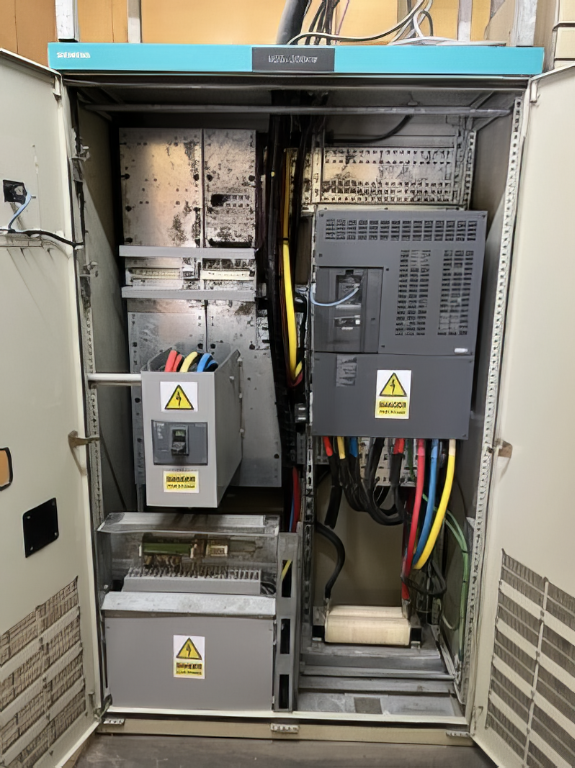

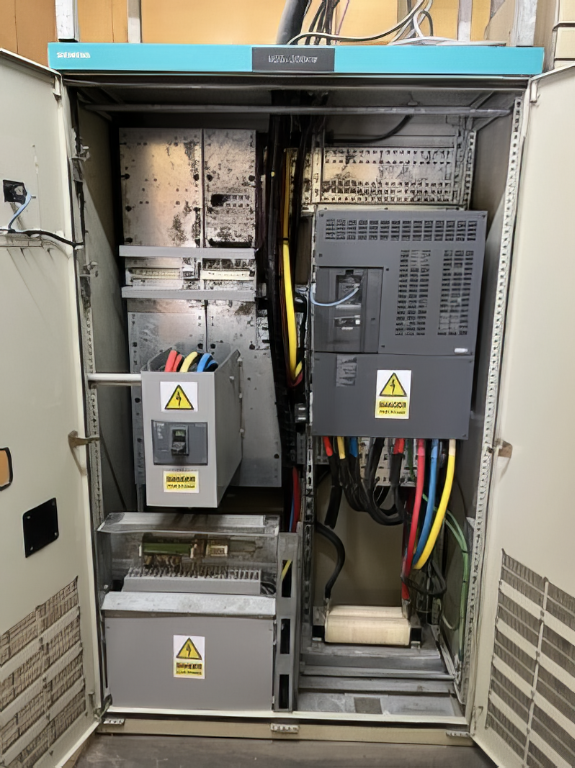

PGB SANTONG - 6.6KV MOTOR DRIVEN FIRE WATER PUMP CONTROL PANEL

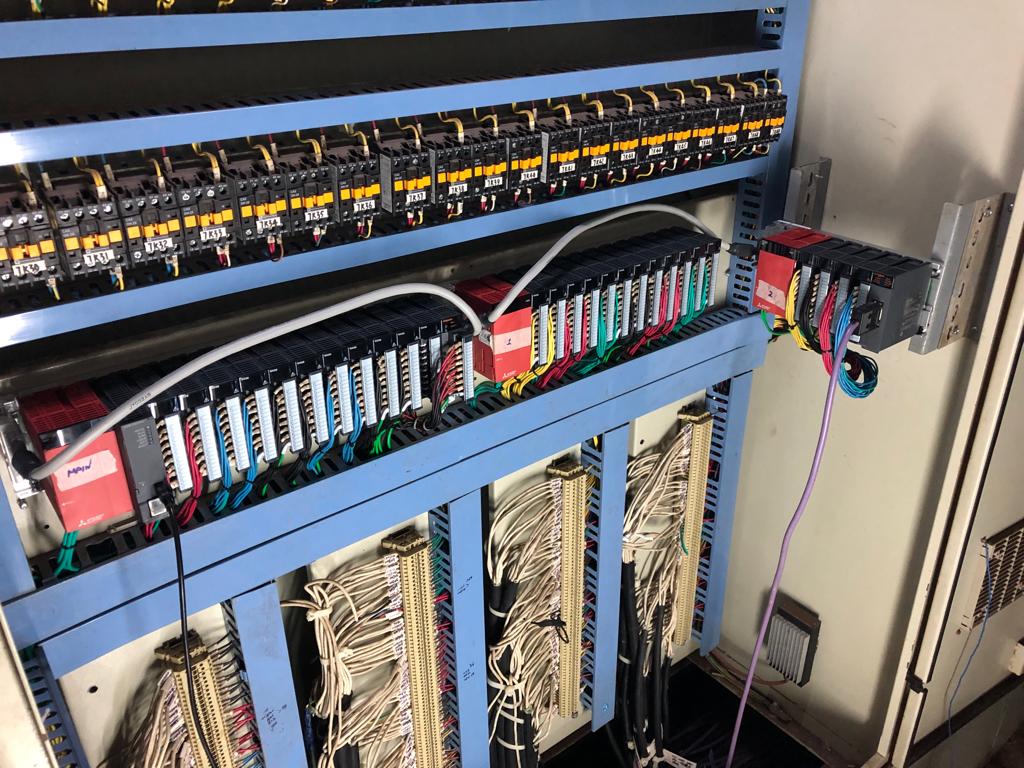

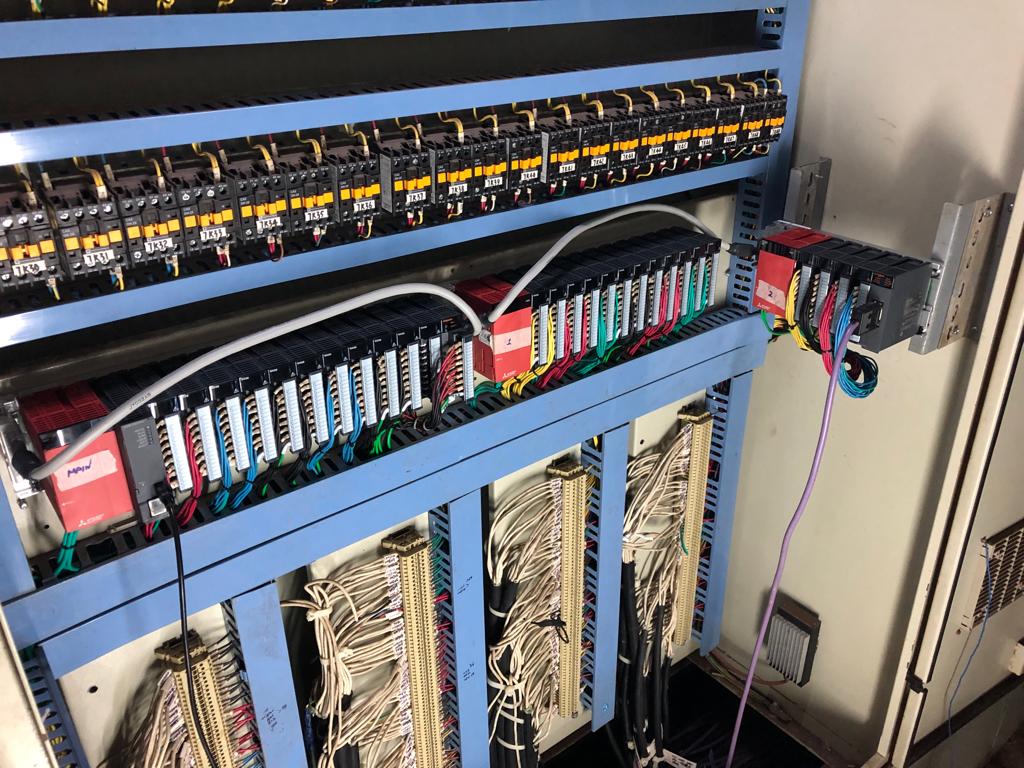

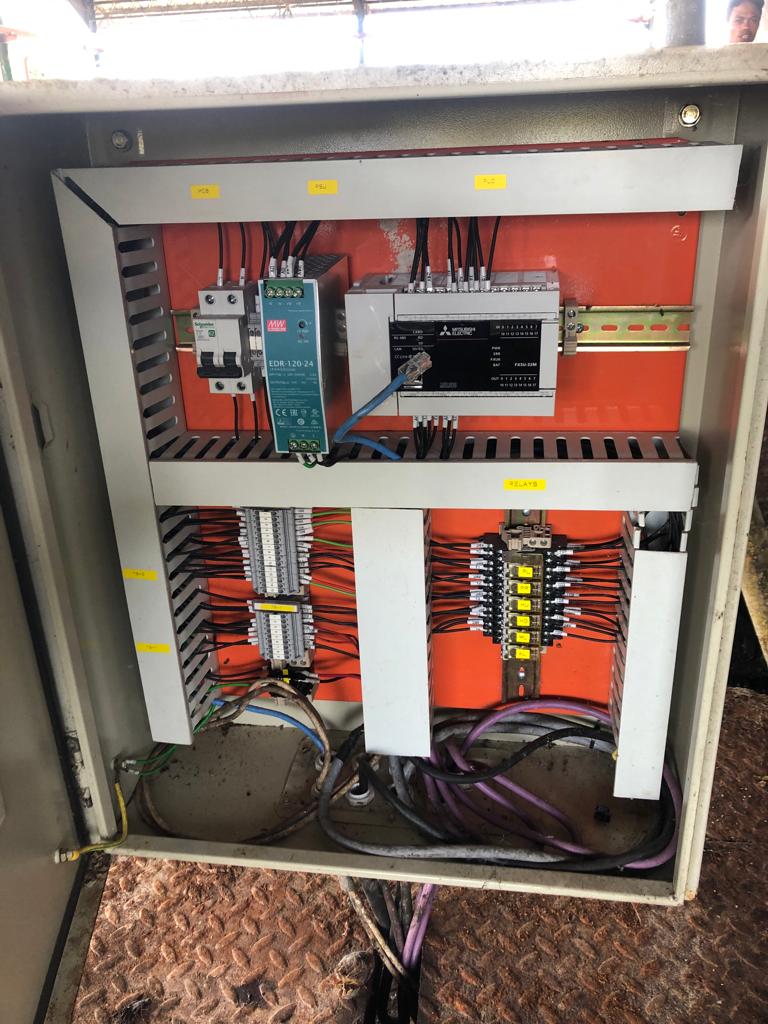

The commissioning of 4 diesel-driven FWP control panels, 2 jockey pump panels, and 2 6.6kV motor-driven FWP panels was upgraded with PLC and HMI tech to NFPA 2.0 standards. Features include deluge valve start, remote start, low water pressure auto start, redundant DC power, and battery charger protection. Equipped with pressure transmitters for enhanced functionality.