In March 2024, Ultech Engineering successfully completed the RANC34 Twin Router CNC Machine Rejuvenation project for Samling Housing Products (SHP), a key player in the general housing product industry. This project aimed to modernize an aging machine and provide enhanced efficiency and reliability to Samling Housing Products' manufacturing line.

Computer Numerical Control (CNC) is an automated manufacturing process that uses preprogrammed computer software to control the movement and precision of machine tools. This technology enhances efficiency by embedding programmed instructions directly into the machines.

CNC is widely applied in manufacturing, particularly for shaping metal and plastic components. It enables automation for various cutting tools, including mills, lathes, routers, drills, grinders, water jets, and lasers. Additionally, CNC extends beyond machining, providing control for processes such as welding, electronic assembly, and filament winding.

Managed by our experienced Automation and Control Engineers, Howard Hu and Wang Zhi Xian, this project aimed to breathe new life into an outdated CNC machine that was an integral part of the house door manufacturing line.

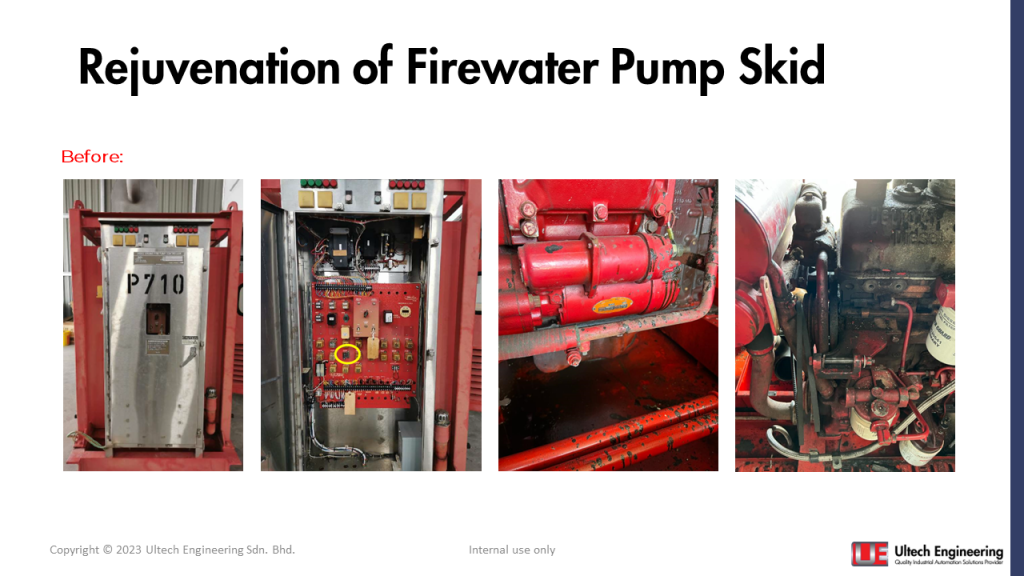

Before the rejuvenation, the machine, although still operational, had begun to show signs of wear and tear. It exhibited various abnormalities, such as inconsistent performance, slow processing speeds, and frequent mechanical issues, all of which were a result of its aging components. These issues had started to pose significant risks to the overall production line, compromising the efficiency, reliability, and consistency of the manufacturing process.

Every project presents unique challenges, and for Ultech Engineering, these are the opportunities to grow, innovate, and refine their expertise. The RANC34 Twin Router CNC Machine Rejuvenation project was no exception. Despite the obstacles, the team remained committed to delivering a high-quality solution for Samling Housing Products.

This project marked Ultech Engineering’s first venture into CNC machine technology and machine building. Unlike their previous experience with industrial automation, CNC systems required the team to learn entirely new concepts, including machine structure, motion control, and operational programming. The learning curve was steep, but the team embraced the challenge, dedicating time to understanding CNC fundamentals and best practices.

In addition to learning CNC technology, the team needed to study servo motor parameters, advanced programming techniques, and the overall control philosophy of CNC machining. These elements were crucial for ensuring smooth machine operation and precision in production. The team conducted extensive research, collaborated with experts, and performed rigorous testing to fine-tune the system, ensuring optimal machine performance.

Despite these challenges, the Ultech Engineering team demonstrated resilience and adaptability. They successfully overcame each hurdle through extensive research, collaboration, and hands-on problem-solving, ensuring a smooth and efficient CNC machine system rejuvenation.

The rejuvenation process selected the Mitsubishi Electric M80V CNC controller and Mitsubishi Electric HG142BS-D48 AC Brushless Rotary servo motor as the key components to bring the CNC machine up to modern standards. These solutions were carefully chosen to enhance precision, efficiency, and reliability.

The Mitsubishi Electric M80V CNC Controller is part of the M8 Series, designed to enhance productivity and precision in machining operations. It offers advanced features tailored to modern manufacturing needs.

The Mitsubishi Electric HG142BS-D48 is a high-performance AC brushless rotary servo motor designed to deliver exceptional precision and reliability in industrial applications. With a rated output of 1.5kW, this motor offers high torque and a compact design, making it ideal for systems where space and performance are critical. The HG142BS-D48 features a built-in 22-bit absolute encoder that provides precise feedback for accurate position and speed control. This ensures smooth operation even under varying loads, which is essential for robotics, CNC machines, and other automated systems that require precise motion control.

Built to meet the demands of high-speed and high-precision applications, the HG142BS-D48 operates at a rated speed of 3000 rpm, delivering consistent power and efficiency. The motor’s brushless design reduces maintenance requirements and increases lifespan, making it a cost-effective choice for long-term operations. Its versatility allows it to be integrated with a variety of Mitsubishi Electric servo drives, further enhancing the performance of industrial automation systems. Whether for high-speed packaging, precision machinery, or robotic applications, the HG142BS-D48 stands out for its combination of high performance, reliability, and ease of integration.

During Factory Acceptance Testing (FAT), no significant feedback was recorded. However, During the Site Acceptance Testing (SAT), the client noticed that the consistency of the margin of error of the wood-cutting was not within the acceptable range. To fix this, Ultech Engineering team quickly adjusted the CNC parameter settings, which improved precision and performance to meet the required standards.

With the successful implementation of the RANC34 Twin Router CNC Machine Rejuvenation, Samling Housing Products Sdn. Bhd. now enjoys multiple advantages that enhance its production efficiency and overall operational reliability.

The upgraded CNC system incorporates modern advancements, ensuring improved precision, efficiency, and reliability in production.

Samling Housing Products Sdn. Bhd. can now rely on Ultech Engineering’s readily available technical support, eliminating the need for expensive overseas assistance and ensuring faster troubleshooting and maintenance.

Before the CNC machine rejuvenation, Samling Housing Products Sdn. Bhd. relied on Japanese manufacturers for troubleshooting and maintenance. This required bringing in specialists from Japan, resulting in high service costs and long waiting times.

With Ultech Engineering providing local technical support, Samling Housing Products Sdn. Bhd. now benefits from faster response times and significantly reduced maintenance expenses, ensuring minimal disruption to production.

To ensure a smooth transition and successful operation of the upgraded CNC system, Ultech Engineering provided extensive on-site training during the project handover. This training focused on equipping Samling Housing Product’s employees with the necessary skills and knowledge to operate and maintain the rejuvenated machine efficiently. The training included:

Employees were trained on how to operate the new Mitsubishi Electric M80V CNC controller, ensuring they could maximize its advanced features for precision manufacturing.

The team provided hands-on training on modifying existing G-code, allowing operators to customize and optimize machining processes as needed.

A crucial part of the training involved identifying and resolving common CNC machine issues, enabling Samling Housing Production’s workforce to address minor problems independently without requiring external support.

By investing in thorough training, Ultech Engineering ensured that Samling Housing Product’s operators were well-prepared to handle the new system with confidence, minimizing operational downtime and maximizing production efficiency.

Beyond the initial handover, Ultech Engineering remains committed to providing continuous support to Samling Housing Product, ensuring the smooth operation of the CNC system. This ongoing assistance includes:

Ultech Engineering sends technical experts directly to Samling Housing Production’s facility when complex issues arise to diagnose and resolve problems efficiently.

For minor challenges, Samling Housing Production can contact Ultech’s support team via phone for quick troubleshooting and guidance, reducing downtime.

To keep Samling Housing Products' (SHP) operators proficient, Ultech Engineering periodically conducts on-site refresher sessions, reinforcing best practices in CNC operation and maintenance.

This continued partnership ensures that SHP can maximize the performance of its rejuvenated CNC machine while benefiting from reliable, cost-effective local support from Ultech Engineering.

The RANC34 Twin Router CNC Machine Rejuvenation project marks a significant milestone for Ultech Engineering, demonstrating the company’s expertise in tackling complex CNC machine challenges. This project showcased the team’s ability to adapt, innovate, and excel in new technologies and reinforced Ultech Engineering's reputation as a trusted local partner for CNC machine solutions. By modernizing Samling Housing Products' CNC machine, Ultech Engineering has provided a cost-effective, future-proof, and sustainable solution, ensuring the client's long-term operational efficiency and reliability.

Beyond this project, Ultech Engineering has successfully delivered numerous machine rejuvenation and industrial automation projects across various industries, helping businesses upgrade aging machinery, optimize manufacturing processes, and enhance production efficiency. With an unwavering commitment to innovation, precision, and customer satisfaction, Ultech Engineering continues to push the boundaries of engineering excellence, making machine rejuvenation, automation, and smart manufacturing solutions more accessible, reliable, and efficient for local manufacturers.

Through years of experience, Ultech Engineering has been involved in various projects across Malaysia, particularly in Sabah and Sarawak. The company has successfully executed projects ranging from CNC machine rejuvenation, control system integration, and VAC (Ventilation and Air Conditioning) solutions to industrial automation and precision engineering. Ultech Engineering has built a strong foundation in delivering customized automation and CNC machine solutions by working with industries in manufacturing, oil and gas, and infrastructure development. This extensive exposure ensures that businesses in East Malaysia benefit from state-of-the-art technology, expert technical support, and long-term operational sustainability.