Ultech Engineering participated virtually in the Rockwell Automation SI Partner Workshop at the end of last month, where Rockwell Automation's Software and Contol Business Lead, Kiam Leng Tay, unveiled a range of FactoryTalk® features to System Integrator Partners. FactoryTalk Analytics is a suite of software tools developed by Rockwell Automation, a leading provider of industrial automation and information solutions. FactoryTalk Analytics is designed to help businesses optimize manufacturing processes by leveraging data analytics and machine learning techniques.

In today's fast-paced industrial landscape, maximizing efficiency and minimizing downtime are paramount. One key component of the FactoryTalk Analytics suite is FactoryTalk Analytics LogixAI. This is where FactoryTalk® Analytics LogixAI® steps in, revolutionizing predictive maintenance and operational optimization. This software specifically focuses on predictive maintenance at the operational technology (OT) level. It uses advanced data modelling and machine learning algorithms to analyze data collected from industrial equipment and processes in real-time. By analyzing this data, FactoryTalk Analytics LogixAI can identify patterns, anomalies, and potential issues before they lead to equipment failures or downtime.

The software integrates directly with Rockwell Automation's Logix platform, commonly used in industrial control systems. This integration allows FactoryTalk Analytics LogixAI to access and analyze data directly from PLCs (Programmable Logic Controllers) and other industrial control devices, enabling rapid decision-making and proactive maintenance strategies. By seamlessly integrating data modelling and machine learning, LogixAI empowers control engineers, even those without extensive data science expertise, to harness the power of advanced analytics. Let's delve deeper into the features and functionalities of this cutting-edge software.

Traditional data modeling often involves complex algorithms and extensive data science knowledge. However, LogixAI takes a different approach by creating mathematical equations that model operational behavior. Unlike object modeling, which focuses on virtual representations like Digital Twins, LogixAI's models adhere to the laws of physics. This enables precise modeling of industrial processes, ensuring accurate predictions and actionable insights.

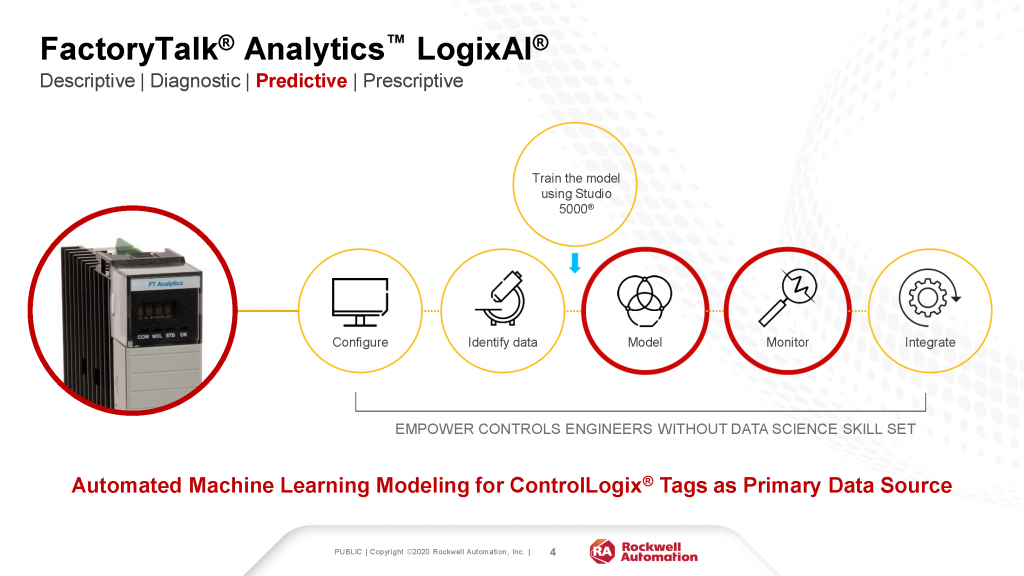

At the heart of LogixAI is its ability to perform automated machine learning modeling using ControlLogix tags as the primary data source. Embedded within the control system chassis, LogixAI's compute module communicates directly with ControlLogix via the backplane. This streamlined integration enables real-time monitoring and analysis of critical operational parameters.

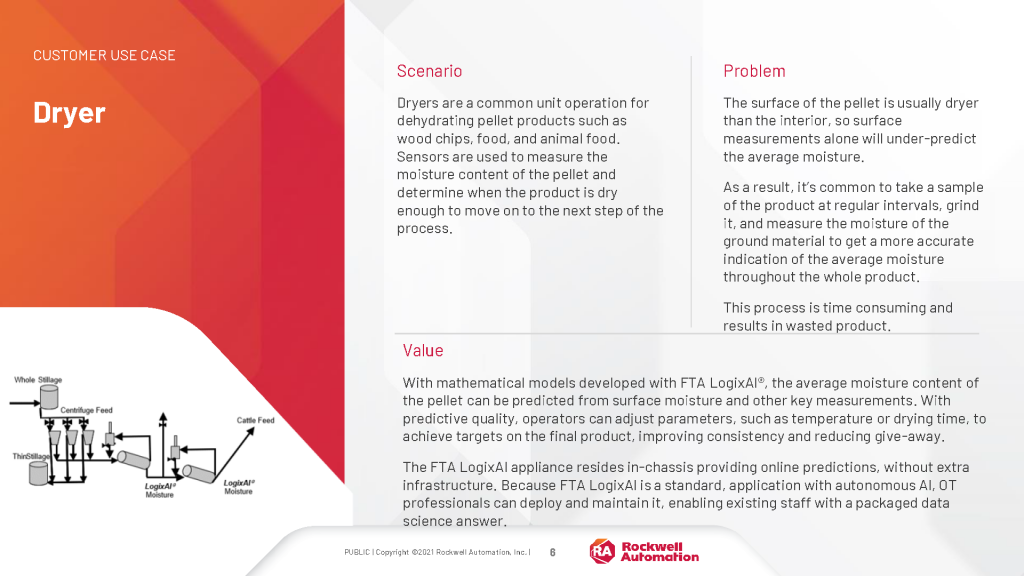

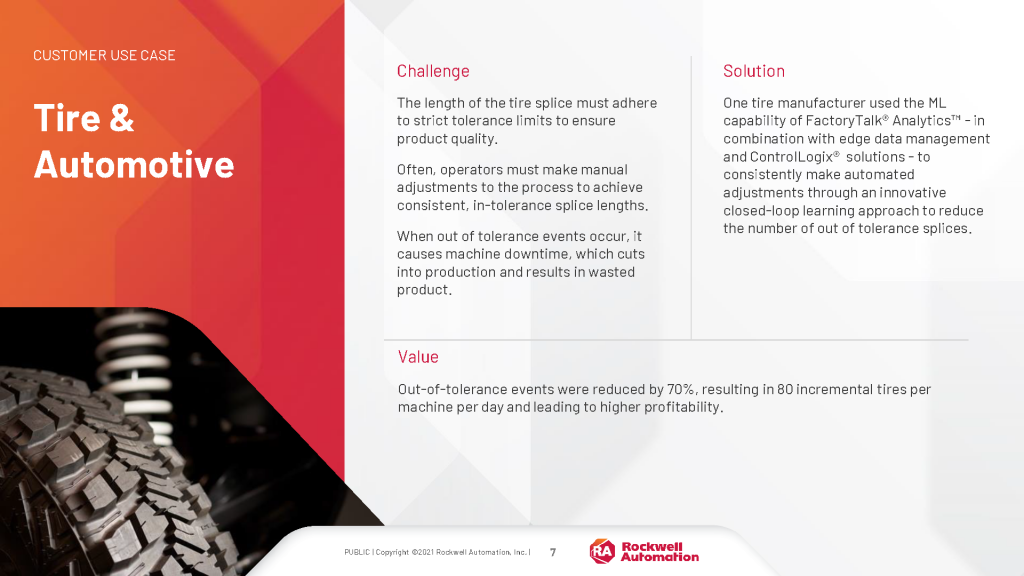

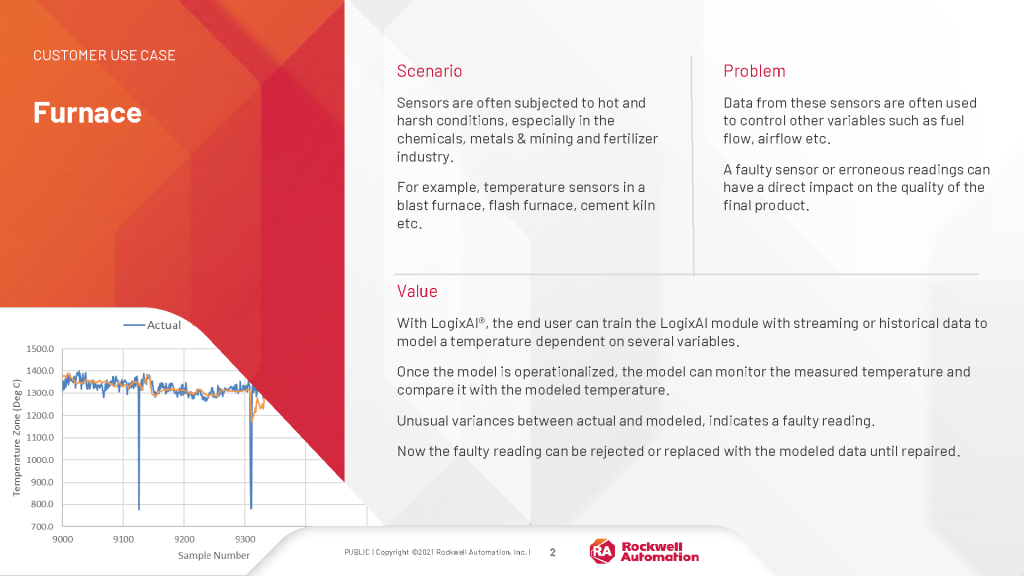

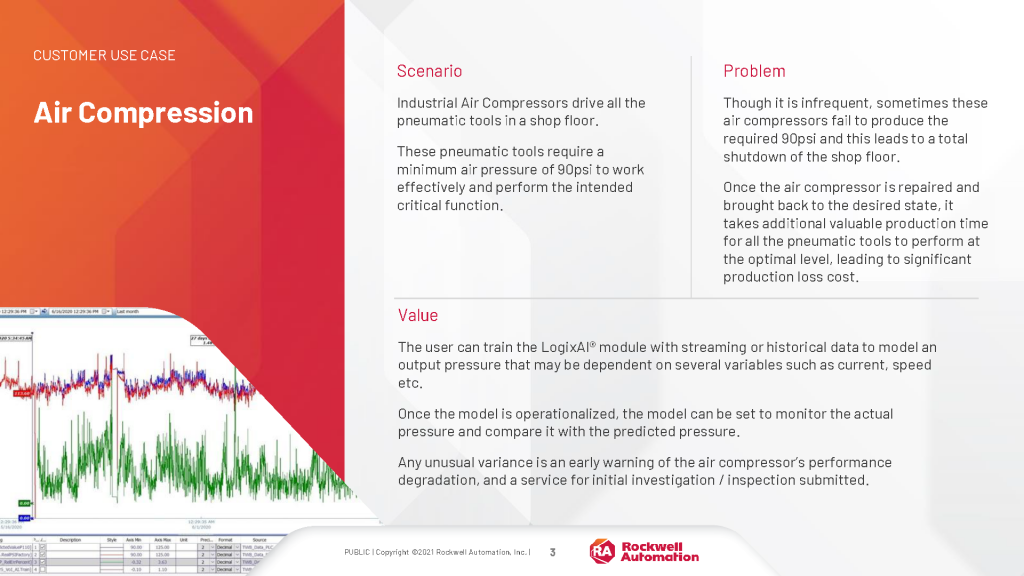

From furnace operations to air compression, rolled products manufacturing and freeze drying, LogixAI caters to a diverse range of industries. Its adaptive capabilities make it an invaluable tool for optimizing processes and ensuring peak performance across various applications.

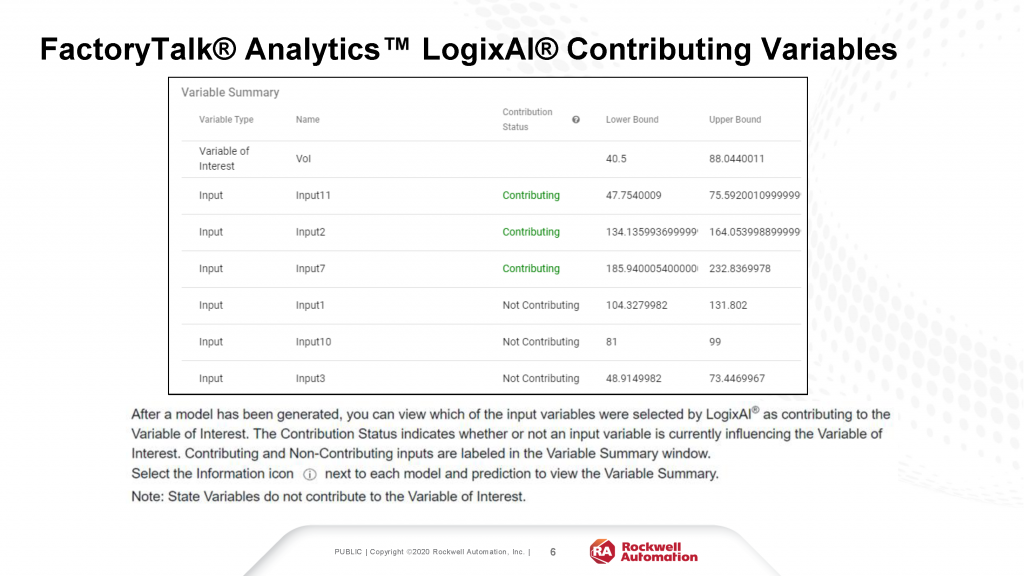

Once a model is generated, LogixAI provides insights into the input variables contributing to the Variable of Interest. This transparency enables engineers to fine-tune models and optimize predictive accuracy.

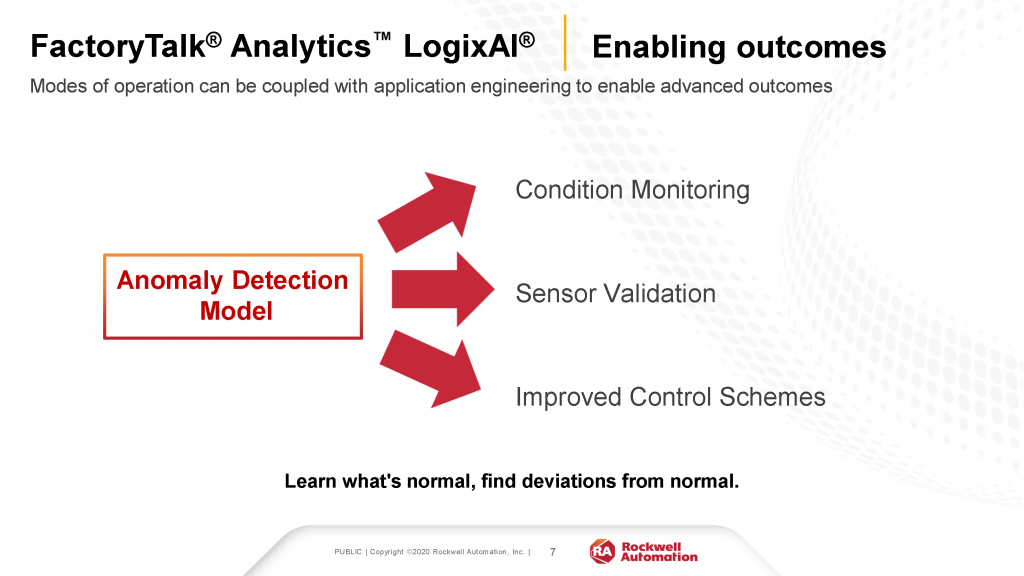

LogixAI's advanced analytics enable a myriad of outcomes, from condition monitoring and sensor validation to improved control schemes. By learning what constitutes normal operation, LogixAI empowers engineers to detect deviations promptly and take proactive measures to mitigate risks.

The workflow of FactoryTalk® Analytics LogixAI® is straightforward yet powerful. Engineers select the variable of interest, choose potential input variables, and let LogixAI's automated modeling process do the rest. With user-defined tag structures and predictive capabilities, LogixAI seamlessly integrates into existing automation systems, enabling engineers to leverage predictions for informed decision-making.

In conclusion, FactoryTalk® Analytics LogixAI® represents a significant leap forward in predictive maintenance and operational optimization. By democratizing advanced analytics and machine learning, LogixAI empowers control engineers to unlock efficiency, reliability, and ultimately, competitive advantage in today's dynamic industrial landscape.

Overall, FactoryTalk Analytics, including FactoryTalk Analytics LogixAI, represents a significant advancement in leveraging data analytics and machine learning technologies to drive efficiency, productivity, and reliability in industrial manufacturing environments.