The Sarawak Energy Bakun Hydroelectric Plant (HEP) is one of Malaysia’s largest renewable energy projects, located in Sarawak. This facility plays a crucial role in providing sustainable energy to the region, powering industries and homes alike. As part of ongoing efforts to enhance its operational efficiency and safety, Sarawak Energy Sdn. Bhd. initiated the Bakun Pressurization Project in 2024. This project aimed to upgrade the current facility of their Ventilation and Air Conditioning (VAC) system, with a state-of-the-art Air Filteration Unit (AFU) Unit, ensuring optimal environmental conditions and advanced fire safety measures.

The project was a collaborative endeavor involving multiple stakeholders:

The initiative reflects Sarawak Energy’s commitment to leveraging cutting-edge technology to maintain world-class standards at its facilities. This project recap provides a detailed account of Ultech Engineering’s contributions, challenges faced, and solutions implemented to ensure the successful completion of the Bakun Pressurization Project.

Ultech Engineering undertook the monumental task of supplying, delivering, installing, testing, and commissioning a VAC system at the Bakun Hydroelectric Plant (HEP). This ambitious project, commissioned in 2024, was designed to support Sarawak Energy Sdn. Bhd., with partnerships including United Credible Sdn. Bhd. as the main contractor and Vision Air-Cond Services Sdn. Bhd. as the instrumentation contractor.

Ultech Engineering Sdn. Bhd. participated in this project as a subcontractor along with Maritime & Industrial Engineers Sdn. Bhd. and this undertaking involved the supply, delivery, installation, testing, and commissioning of a VAC (Ventilation and Air Conditioning) system, more specifically the AFU (Air Filteration Unit) system at Bakun Hydroelectric Plant (HEP). The project’s successful completion stands as a testament to the technical prowess and dedication of the Ultech Engineering team.

The project was spearheaded by Project Manager and Engineer Wang Zhi Xian, with support from team members, Automation and Control Engineers Ellysha Astin and Mike Gaby Law. Ultech Engineering’s primary responsibility was the design, installation, and commissioning of motor control cabinets, specifically the MCC-CCR and MCC-RIO1 panels. These were interfaced with three junction boxes and installed in both the control room and the VAC hall (outdoor).

The main project scope work included:

Additional tasks included the delivery, supply, and installation of trunking/tray and cables, wire termination, and system rectification. While trunking/tray installation and cable laying were primarily managed by the partnering wiremen team, Ultech Engineering stepped in to support these efforts towards the project’s conclusion.

The primary objective of the Air Filtration Unit (AFU) system is pressurization. When the system starts, the motor draws air into the room, with its speed modulated by the PLC to match the specified setpoint. For instance, if the Common Supply Air Pressure setpoint is 100 Pa, the motor speed adjusts accordingly. Should the duty motor be unable to reach the setpoint, the standby motor starts to support it and stops once the setpoint is achieved. Additionally, after a designated service duration, such as 1440 minutes, the duty motor will stop, and the standby motor will take over. This alternating operation ensures consistent performance and equipment longevity.

Start Sequence:

Stop Sequence:

Each AFU unit comprises two motors, two filter differential transmitters, two outlet motorized dampers, and one common supply air pressure sensor, all installed outdoors. A total of five AFUs were implemented in this project.

The Motor Control Center (MCC) panels play a crucial role in the system's functionality. These panels include circuit breakers, relays, fuses, PLC modules, and network switches, ensuring the seamless operation of the AFU system.

Working in a remote and rural location like Bakun presents unique challenges that demand adaptability, resilience, and ingenuity. This project required Ultech Engineering’s team to navigate logistical constraints, communication barriers, and environmental factors, all while upholding the highest standards of engineering excellence. Despite these obstacles, the successful completion of the Bakun Pressurization project brought a profound sense of purpose and achievement to the entire team.

The multi-stakeholder nature of this project presented significant communication challenges. Ultech Engineering had to coordinate with:

To address this, the team maintained transparency by sharing daily site reports with pictures and frequent updates. This practice not only kept stakeholders informed but also ensured that client expectations were consistently met.

Outdoor tasks were frequently disrupted by adverse weather conditions. The team adapted by prioritizing indoor work during poor weather and rescheduling outdoor tasks for favorable conditions.

The physical layout of the worksite posed logistical challenges. With tools and materials stored at the ground floor loading bay, team members often had to traverse significant distances to reach work locations such as the rooftop, jackroof, and the level 2 basement of the powerhouse. Strategic planning during general working hours (8 AM to 9 AM) helped minimize unnecessary movement and conserve energy.

The absence of nearby accommodations within the dam area added to the complexity. The team stayed in Sungei Asap, approximately 45 minutes to an hour away from Bakun Dam. This necessitated careful scheduling and efficient travel management.

Occasional shortages of tools and materials required the team to borrow equipment from contractors on-site. All borrowed items were promptly returned to maintain good working relationships.

Despite these challenges, the team’s determination and collaborative efforts enabled them to overcome obstacles effectively. The completion of the Bakun Pressurization project stands as a testament to Ultech Engineering’s adaptability and problem-solving prowess. Projects in such remote locations may be demanding, but they also inspire a deep sense of fulfillment, knowing that each milestone achieved contributes to the advancement of essential infrastructure in the region.

In the Bakun Pressurization project, Ultech Engineering implemented advanced equipment to ensure efficient and reliable operation of the Air Filtration Unit (AFU) system. Ultech Engineering employed advanced technology, including:

These systems were designed to:

Here's an overview of the key components:

The SIMATIC ET 200SP is a versatile and compact distributed I/O system designed for efficient control in industrial settings. Its modular design allows for easy scalability and integration into various automation solutions. Key features include:

The SIMATIC HMI MTP1000 is a high-performance Human-Machine Interface (HMI) panel that provides intuitive operation and monitoring of industrial processes. Its notable features include:

These components were integral to the project's success, providing robust control and monitoring capabilities essential for the AFU system's operation. Their advanced features and reliability contributed significantly to meeting the project's objectives and ensuring long-term performance.

For more detailed specifications, please refer to the official Siemens product pages:

Conducted internally at Ultech Engineering’s office, FAT received no direct client feedback.

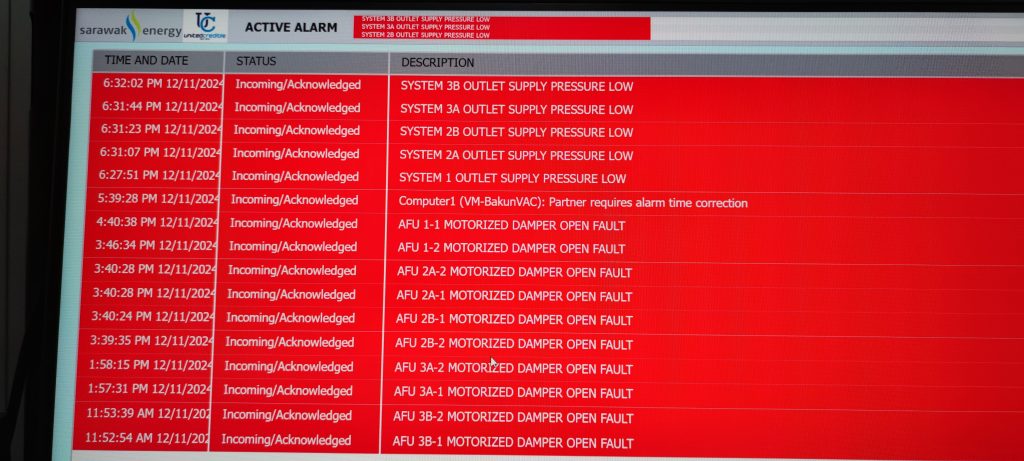

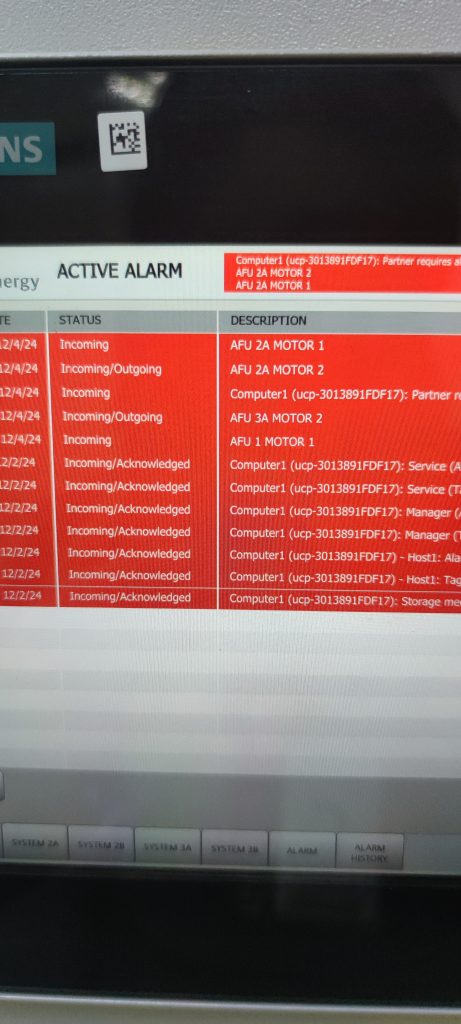

Throughout the project, Ultech Engineering’s efforts were well-received. During the Site Acceptance Testing (SAT), feedback from the client included suggestions to enhance functionality and improve hardware. These inputs were swiftly implemented, ensuring the client’s expectations were not only met but exceeded.

The implementation of the Air Filtration Unit (AFU) system provided Sarawak Energy Sdn. Bhd. with a reliable air supply to critical rooms. This advancement enhanced operational efficiency and safety at the Bakun HEP.

Following project completion in January 2024, Ultech Engineering provided the client with operational manuals for SCADA and HMI systems. Training sessions conducted by Automation Head Engineer Wang ensured the client’s team was well-equipped to manage the new systems and ensure sustained performance.

Ongoing support activities for the future demonstrate our dedication to service excellence and they include:

The Bakun Pressurization project underscores Ultech Engineering’s commitment to excellence in delivering turnkey engineering solutions. By overcoming logistical, environmental, and interpersonal challenges with better planning and effective project management techniques, the team successfully commissioned a cutting-edge VAC system, AFU control unit, that meets the client’s needs. This accomplishment not only strengthens Ultech Engineering’s reputation but also reinforces its position as a leader in the engineering industry.