In August 2025, Ultech Engineering successfully completed a critical SCADA migration project for Shell MDS Sdn Bhd, enhancing the operational efficiency and reliability of their Wax Plant. The project, Shell MDS Wax Plant SCADA Migration, was led by our Project Automation Manager, Mr. Wang Zhi Xian, with the assistance of junior engineers, Ellysha Austin, and Adam Kauline, and focused on modernizing the plant’s control system while addressing longstanding hardware and system issues.

Located in Bintulu, Sarawak, Shell MDS (Malaysia) Sdn Bhd operates using Shell’s proprietary Shell Middle Distillate Synthesis (SMDS) process — a technology built upon more than 3,500 patents that converts natural gas into high-quality hydrocarbon liquids. From these hydrocarbon liquids, Shell MDS produces a range of premium products, including GTL waxes, drilling fluids, and specialty chemicals.

The end products derived from this process contain minimal impurities such as sulphur, aromatics, and nitrogen, making them cleaner, safer, and more environmentally friendly compared to those produced from crude oil. Through continuous innovation and advanced technology, Shell MDS contributes to cleaner energy solutions while supporting industrial development in Malaysia and globally.

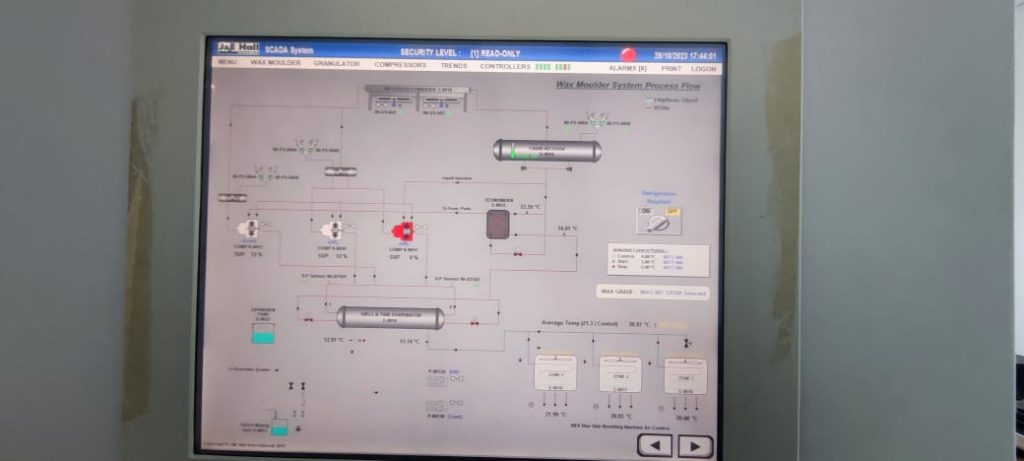

The Shell MDS Wax Plant operates with a complex wax moulder system and a granulator system that demand real-time monitoring, precise control, and responsive alarm handling to maintain smooth and safe production. The old SCADA system had been facing hardware failures, touchscreen malfunctions, and unreliable alarm triggers, which led to operational inefficiencies and potential process interruptions.

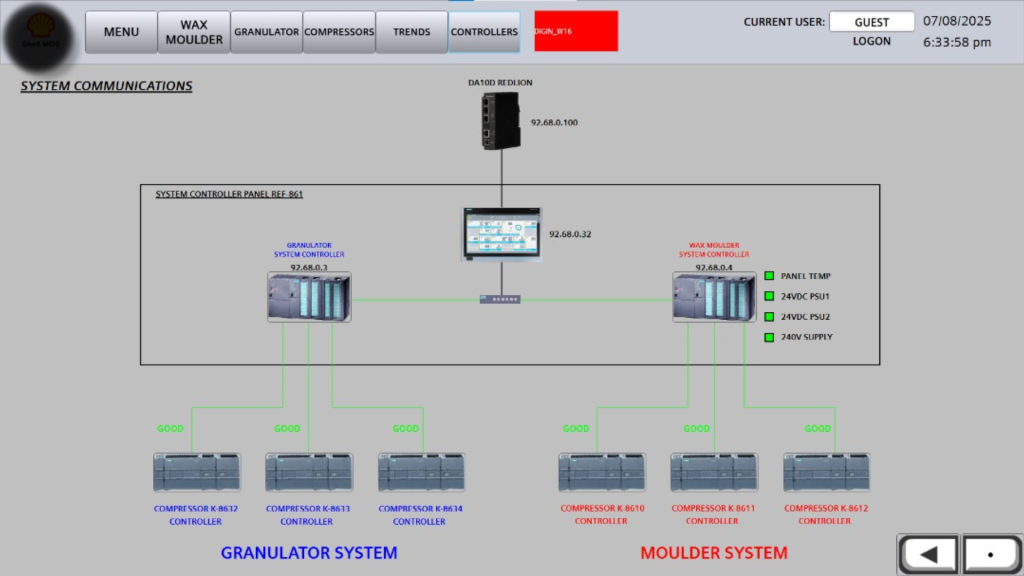

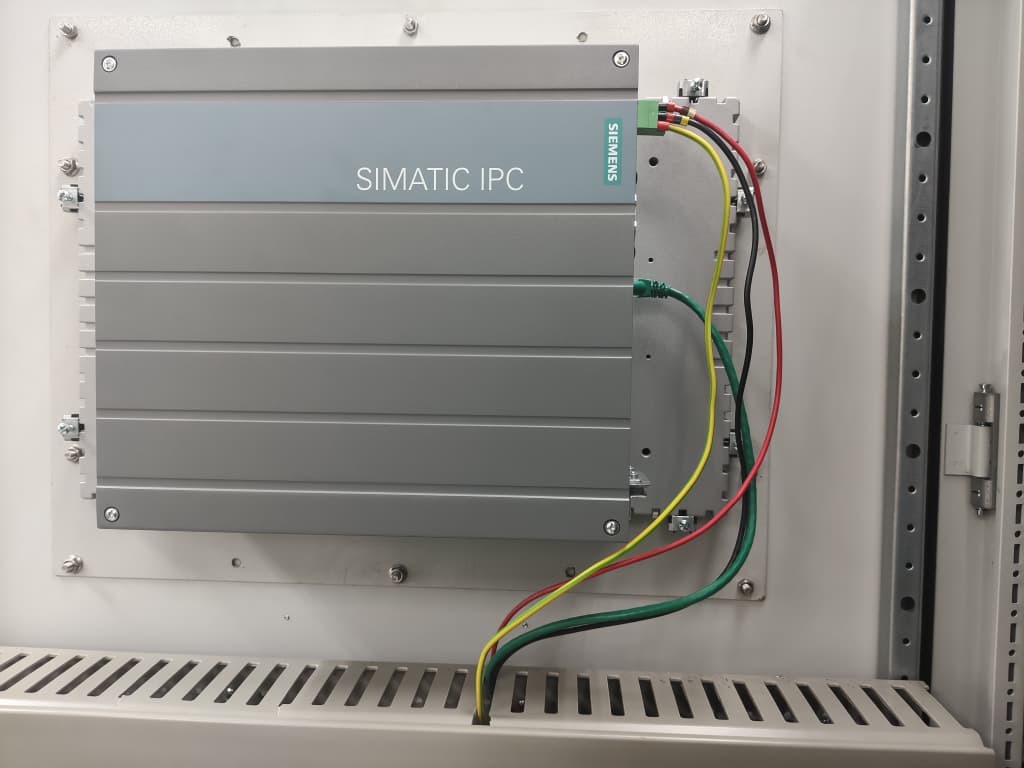

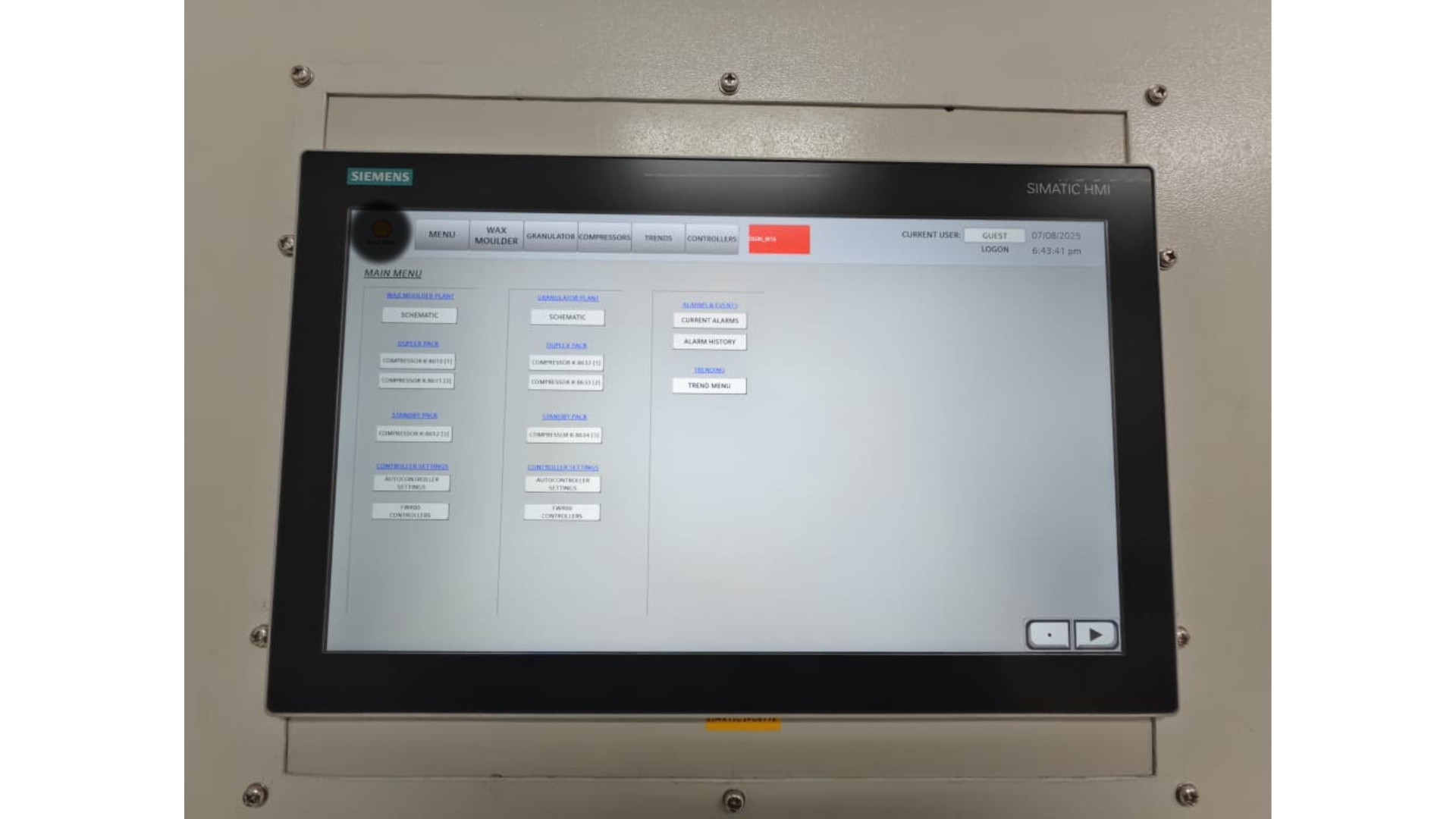

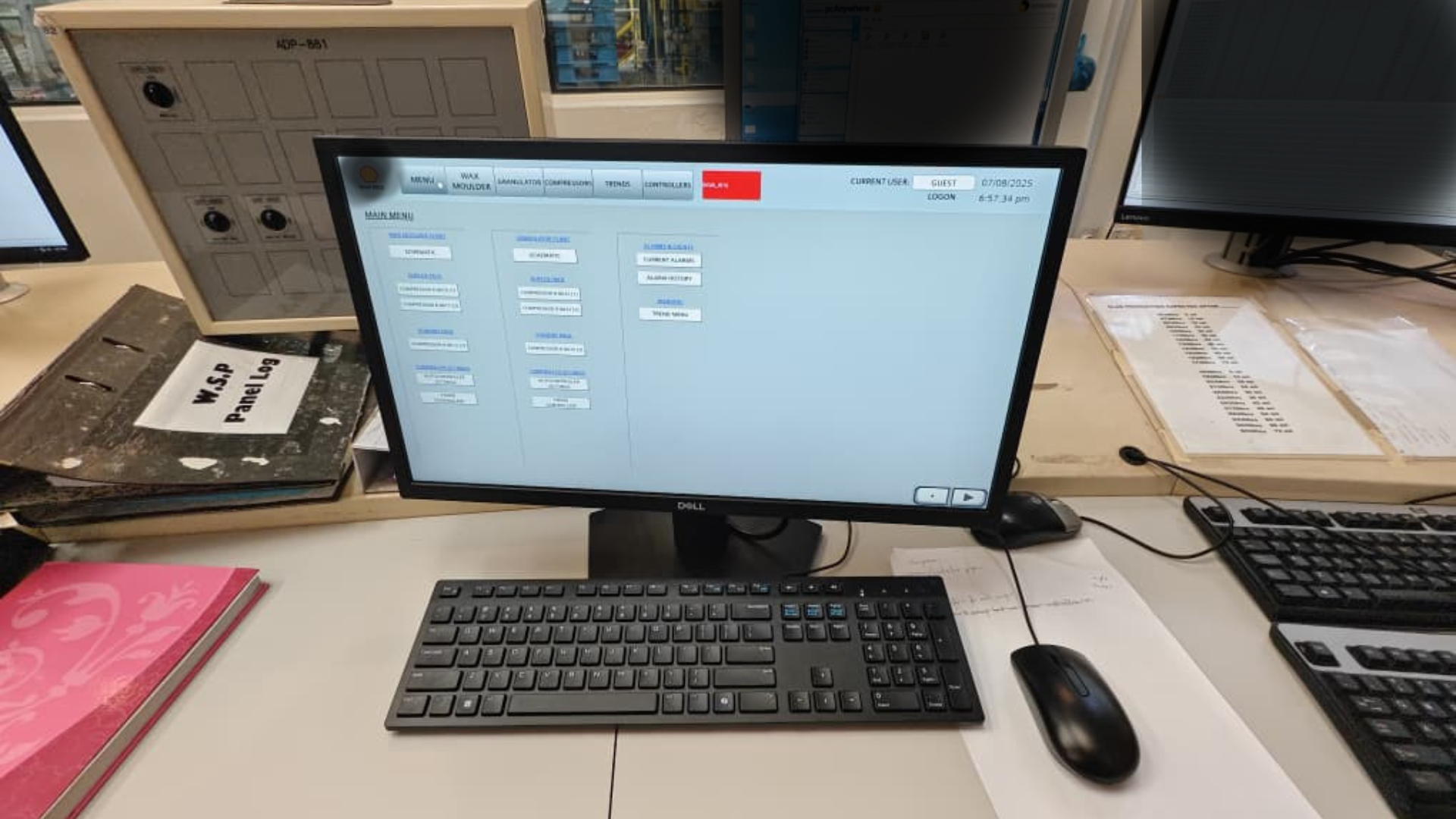

To address these challenges, Ultech Engineering migrated the plant’s SCADA system to the Siemens Unified Comfort platform using TIA Portal v19, providing a more reliable, modern, and efficient control environment. The new system was supported by robust hardware, including the Siemens SIMATIC IPC677E Panel PC as the main operator interface and the Dell Precision 3460 Small Form Factor Workstation for SCADA engineering and visualization tasks. Additionally, a Redlion Gateway was integrated as a Modbus communication bridge, enabling seamless data exchange between the upgraded SCADA system and existing field devices.

Through this upgrade, operators can now control both the wax and granulator systems, monitor equipment status, manage alarms, and analyze process trends in real time. The integration of modern technologies and high-performance hardware not only enhanced system responsiveness and accuracy but also strengthened connectivity and reliability, ensuring continuous and efficient production at the Shell MDS Wax Plant.

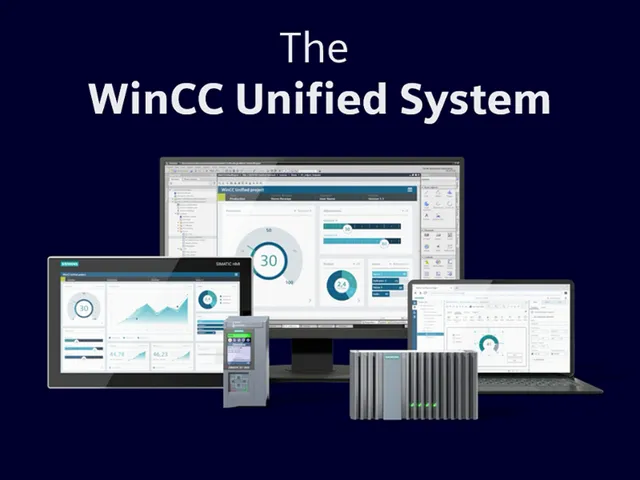

The Siemens WinCC Unified Comfort platform served as the foundation of the new SCADA system, offering a modern, intuitive interface designed for enhanced usability and flexibility. Its advanced visualization tools allow operators to monitor real-time data, alarms, and process trends more effectively. The platform’s seamless system integration also supports improved communication between devices, ensuring smoother plant operations and more efficient decision-making. This upgrade has transformed the Wax Plant’s monitoring and control capabilities into a smarter, more connected environment.

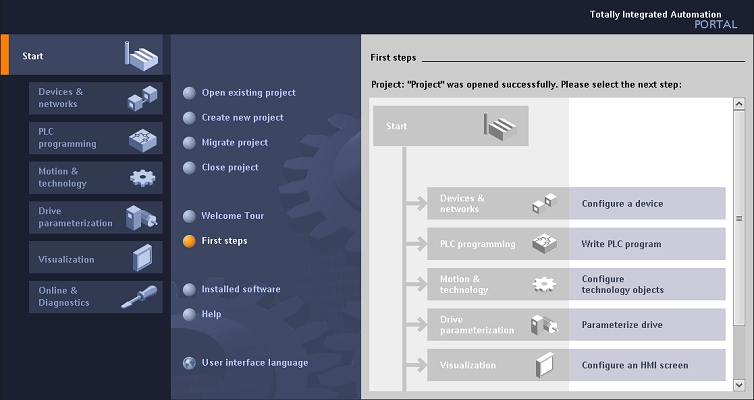

Supporting the SCADA migration, TIA Portal v19 played a crucial role in simplifying engineering, programming, and maintenance tasks. Siemens’ latest integrated engineering framework enables efficient configuration and diagnostics of the control system within a single unified platform. This not only reduces commissioning time but also enhances system reliability through centralized data management. By implementing TIA Portal v19, Ultech Engineering ensured that the Wax Plant’s control infrastructure remains scalable, efficient, and ready for future technological advancements.

The Siemens SIMATIC IPC677E Panel PC was selected as the main interface for the new SCADA system. Known for its powerful performance and industrial-grade reliability, this all-in-one panel PC provides exceptional computing power and durability for continuous operation in demanding environments. Its high-resolution display offers clear process visualization, while its fanless design ensures long-term stability with minimal maintenance. By integrating the IPC677E, the Wax Plant operators can now monitor processes, manage alarms, and control operations through a responsive and intuitive platform.

The Precision 3460 Small Form Factor Workstation serves as the backbone for SCADA engineering and visualization tasks. Compact yet powerful, this workstation supports the Siemens Unified Comfort system and TIA Portal software with seamless performance. It enables engineers to configure, program, and maintain the SCADA system efficiently while handling large datasets and graphical elements with ease. Its reliability and processing speed ensure that system updates, diagnostics, and maintenance activities can be executed smoothly, contributing to the overall stability and efficiency of plant operations.

The Redlion Gateway plays a crucial role in facilitating communication between the new SCADA system and existing field devices. It serves as a Modbus communication gateway, enabling the integration of legacy devices with the upgraded SCADA platform. This ensures that data from various equipment is accurately collected and transmitted in real time for monitoring and control. By implementing the Redlion Gateway, Ultech Engineering successfully bridged the gap between old and new systems, creating a unified and reliable communication network that enhances data flow and system interoperability.

At the beginning of the project, one of the main challenges faced by the team was miscommunication between Ultech Engineering and the client. Differences in understanding and unclear requirements led to delays and the need for frequent clarifications. To resolve this, Ultech Engineering implemented a more structured and transparent communication approach. Daily timesheets were introduced to keep both parties informed of progress, while morning briefings helped align the team’s goals and priorities. In addition, an active feedback loop ensured that any client concerns were addressed promptly. These initiatives significantly improved coordination, reduced misunderstandings, and kept the project moving efficiently toward completion.

Another major challenge was managing the team’s well-being during the intensive SCADA migration process. The nature of the work required long hours and sustained focus, which could easily lead to fatigue and decreased productivity. Ultech Engineering placed strong emphasis on creating a healthy work rhythm to keep morale high. The team adopted one-hour daily breaks, designated Sundays as rest days, and allowed flexible evening breaks during overtime sessions. This thoughtful balance between work and rest helped the engineers maintain their energy, focus, and motivation, ensuring consistent performance throughout the project’s duration.

During the Site Acceptance Testing (SAT) phase, the client highlighted several areas that required improvement.

Firstly, certain triggered alarms were not standing alarms, and some unnecessary alarms appeared on the system. Ultech Engineering promptly reviewed and refined the alarm configurations to ensure only relevant and actionable alarms were displayed.

Secondly, logging tag errors were observed due to missing licenses. The team quickly resolved this by installing the appropriate licenses, restoring full logging functionality, and eliminating the pop-up errors.

Lastly, on the compressor/pump priority screen, unselected components were being reset to OFF when selected ones were turned OFF. Ultech Engineering adjusted the system logic to maintain the correct operating state of unselected components.

All identified issues were rectified before the final handover, resulting in a fully functional, stable, and user-friendly SCADA system that met the client’s operational standards.

The upgraded system. The migration to the Siemens Unified Comfort platform has significantly enhanced system functionality and performance. Operators now have access to a modern interface with improved navigation, clearer data visualization, and smoother control response. The upgraded system also supports better alarm management, trend monitoring, and data logging, allowing operators to detect and respond to plant conditions more efficiently. This modernization not only improves day-to-day operations but also ensures the system remains scalable and compatible with future technology upgrades.

The existing hardware issue has been cleared. Before the migration, the Wax Plant faced frequent issues with its old hardware, including unresponsive touchscreens and unreliable alarm triggers. With the installation of new components such as the Siemens SIMATIC IPC677E Panel PC and Precision 3460 Workstation, these problems have been fully resolved. The upgraded hardware offers enhanced stability, faster processing, and improved durability to withstand continuous industrial operations. As a result, the plant now benefits from a more dependable and efficient control system that minimizes downtime and maintenance needs.

The client was trained to navigate through the new SCADA interface efficiently. This included familiarization with the layout, menus, and key functions to help operators monitor and control plant processes smoothly.

Training covered how to manage and acknowledge alarms, as well as how to view and analyze process trends. This enabled operators to identify system conditions quickly and make informed decisions to maintain safe and efficient operations.

Ultech Engineering guided managing user access through role-based logins with passwords. This ensures that only authorized personnel can perform specific actions, enhancing security and accountability within the system.

Ultech Engineering continues to provide responsive support to ensure the system’s smooth operation even after the project handover. The latest assistance was given when the client encountered an issue where trends were not visible, and control buttons could not be operated from the client's PC. The Ultech team promptly investigated and resolved the issue, restoring full system functionality. This ongoing support reflects Ultech Engineering’s commitment to long-term client satisfaction and reliable system performance.

The project has been completed and officially handed over to Shell MDS. With the new SCADA system fully operational, the Wax Plant now benefits from improved performance, reliability, and ease of operation. The migration marks a significant milestone for both Shell MDS and Ultech Engineering, showcasing effective collaboration, technical excellence, and commitment to delivering quality solutions.

Although the project is now closed, Ultech Engineering remains committed to providing ongoing support whenever needed, ensuring the system continues to perform optimally. This successful handover reinforces Ultech’s reputation as a trusted automation partner, capable of delivering reliable and future-ready control system solutions.

Coming soon!