In October 2023, Ultech Engineering successfully completed the Provision of Hazardous Zone 2 NFPA20 Controller Standard and Secondary Starting System Upgrading project for the Seligi Platform, operated by ENQUEST. This vital upgrade focused on modernising the emergency fire water pump control system, improving operational safety and reliability in a Zone 2 hazardous area.

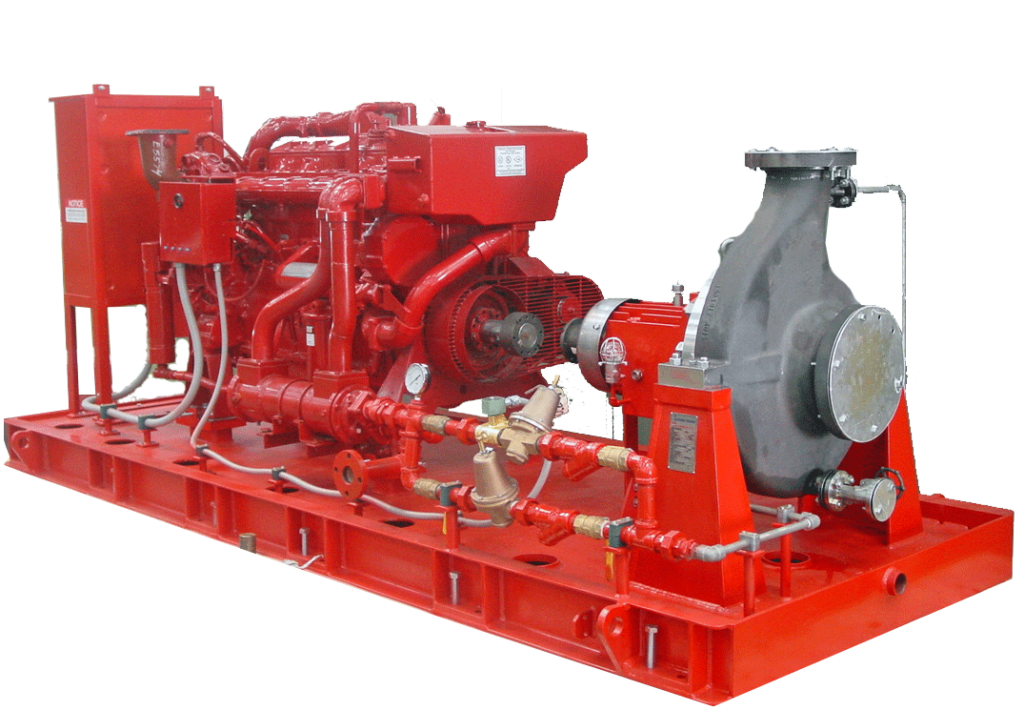

The Fire Water Pump (FWP) system supplies high-pressure water to the platform’s firefighting network and is driven by an engine that starts automatically during a fire. Designed to run until failure or manual shutdown, it ensures continuous water flow during emergencies. In the event of a fire, these systems must start instantly and run continuously until manually stopped or until failure. There is no room for delay or premature shutdown.

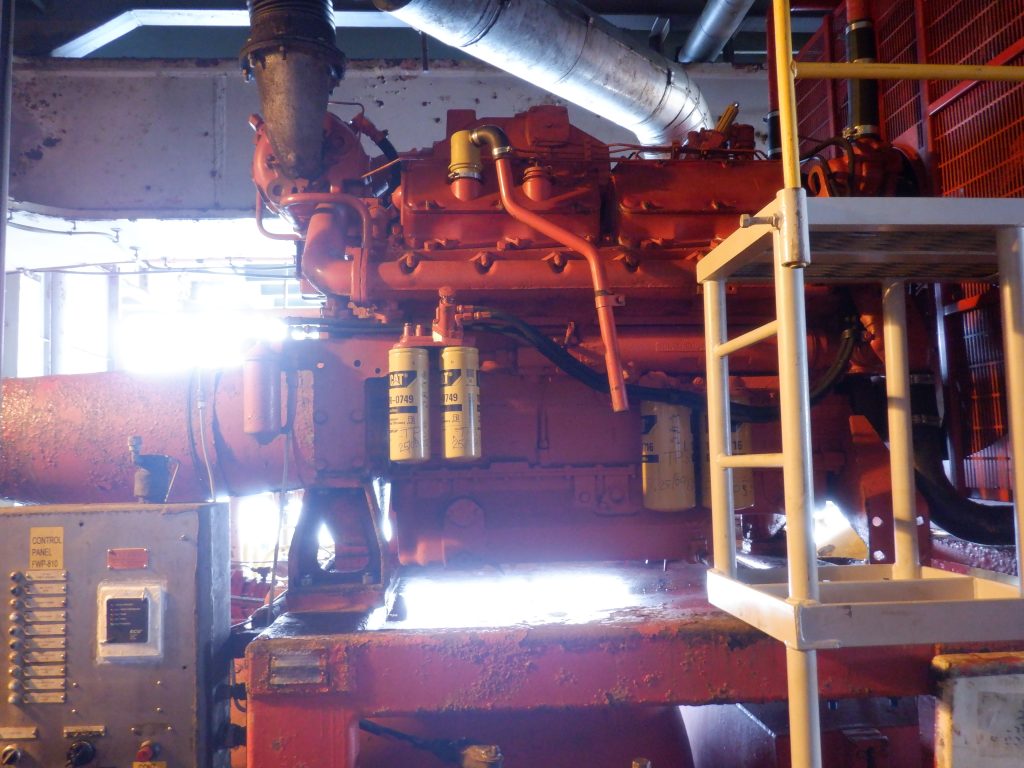

Led by Engineer-in-Charge Howard Hu, the project was carried out for ENQUEST at the Seligi Platform in the oil and gas industry, involving the provision of a Hazardous Zone NFPA 20 Controller and secondary starting system upgrades. The initiative was driven by the need to address a severely deteriorated control panel that had undergone heavy, undocumented modifications, posing serious operational and safety risks.

Although the equipment was still operational before the upgrade, it was in very poor condition. The unit was critical to emergency response, and if it failed, the impact would be severe. Multiple modifications had been carried out over the years, but the as-built drawings were not updated, further complicating maintenance and troubleshooting. Additionally, the emergency fire water pump was equipped with only a single pneumatic starter, which had proven to be frequently unreliable.

Commissioned in December 2022 and successfully completed in October 2023, the upgraded control panel was certified for Zone 2 hazardous areas, ensuring compliance with stringent safety standards. The primary objective was to enhance system reliability, safety, and functionality through the integration of modern control features.

One of the key challenges encountered during this project was that it marked Ultech Engineering’s first exposure to designing and implementing an explosion-proof control panel. Navigating the stringent requirements for Zone 2 hazardous areas demanded a steep learning curve, from component selection to panel integration and certification. Despite this, the team successfully delivered a compliant and reliable solution, reinforcing Ultech’s capability to handle complex, high-risk environments.

Old Local Control Panel

To enhance the reliability and functionality of the fire water pump system, Ultech Engineering implemented a modern control architecture using the Siemens S7-1200 PLC and Siemens SIMATIC Series TP700 Comfort HMI Panel. This setup delivered a powerful, open-source, and non-proprietary solution, making future troubleshooting and support significantly easier.

The control system featured a fully integrated HMI that enabled alarm logging, active alarm viewing, pump status overview, and real-time monitoring of analog signals. Operators also gained full visibility and control over the pump’s start sequence and system status. Built on high-level communication protocols, the upgraded system allows for improved diagnostics and integration with the Centralized Control System, ensuring timely response and operational transparency.

The S7-1200 controller provides the flexibility and power to control a wide variety of devices

in support of your automation needs. The compact design, flexible configuration, and

powerful instruction set combine to make the S7-1200 a perfect solution for controlling a

wide variety of applications.

The CPU combines a microprocessor, an integrated power supply, input and output circuits,

built-in PROFINET, high-speed motion control I/O, and on-board analog inputs in a compact

housing to create a powerful controller. After you download your program, the CPU contains

the logic required to monitor and control the devices in your application. The CPU monitors

the inputs and changes the outputs according to the logic of your user program, which can

include Boolean logic, counting, timing, complex math operations, and communications with

other intelligent devices.

The CPU provides a PROFINET port for communication over a PROFINET network.

Additional modules are available for communicating over PROFIBUS, GPRS, RS485 or

RS232 networks.

1. Compact Design

With dimensions of just 100 (H) x 90 (W) x 75mm (D), the S7-1200 fits easily into control panels with limited space—perfect for compact industrial applications.

2. Industrial-Grade Power Supply

Operates on 24V DC, making it well-suited for a wide range of industrial automation environments.

3. Flexible Programming Options

Supports LAD (Ladder Logic), FBD (Function Block Diagram), and SCL (Structured Control Language)—allowing engineers to choose the most effective method for their application.

4. Integrated Ethernet Port

Features a standard Ethernet communication port for easy configuration, networking, and integration into existing systems.

5. On-Board Diagnostic LEDs

Equipped with status LEDs for power, run/stop, and fault conditions—enabling quick, at-a-glance diagnostics and faster troubleshooting.

The SIMATIC HMI TP700 Comfort Panel is part of Siemens' Comfort Panel series, designed to meet demanding visualization tasks in industrial automation environments. With its high-resolution display, powerful processor, and robust construction, the TP700 Comfort Panel ensures intuitive and reliable operator control of machines and systems.

1. IP65-Rated Protection

The front panel is fully dust-tight and resistant to low-pressure water jets, making it ideal for harsh industrial environments.

2. High-Quality Visualisation

Displays up to 16 million colours, enabling detailed and vivid process graphics for enhanced operator awareness.

3. Intuitive Graphical Interface

A user-friendly touchscreen interface allows for smooth navigation, simplified operation, and real-time system monitoring.

4. Robust and Durable Build

Constructed with a die-cast aluminum front, offering excellent resistance to corrosion and mechanical wear for long-term reliability.

With the upgraded solution fully in place, ENQUEST now operates with a system designed for resilience, safety, and long-term efficiency—specifically tailored for Zone 2 hazardous areas. The benefits are both immediate and lasting:

The new control panel is fully certified for Zone 2 environments, significantly boosting operational safety and ensuring full compliance with hazardous area standards. To further enhance safety, several key features were implemented:

Ultech Engineering provides practical support options, both onsite and remotely, based on client needs. From basic troubleshooting guidance to minor logic assistance, the team ensures that system support remains accessible.

The system is built using an open-source and non-proprietary controller, which not only makes troubleshooting easier for maintenance teams but also provides greater flexibility and control, eliminating the risk of being locked into a single vendor for future upgrades or support.

To ensure a smooth handover and empower the client’s operations team, Ultech Engineering provided a structured, hands-on training program covering all key aspects of the new system:

Operators and maintenance personnel were guided through the structure and flow of the Siemens S7-1200 PLC ladder logic. This included understanding the logic sequences for start-up, shutdown, and interlock conditions, allowing the team to interpret, monitor, and make basic modifications if required.

A detailed walkthrough of the system’s normal and emergency operations was provided, covering both pneumatic and hydraulic starter sequences, HMI navigation, alarm acknowledgment, and manual control features.

Technicians were trained to identify and resolve common system issues, such as starter failure detection, low-pressure alerts, communication faults, and how to perform logic updates via the SD card plug-and-play feature.

This targeted training approach ensured that the client’s team was well-equipped to operate and maintain the system independently, increasing confidence and minimizing future downtime.

The successful upgrade of the fire water pump control system at ENQUEST's Seligi Platform marks a significant milestone for Ultech Engineering. As their first deployment of an explosion-proof control panel, the project showcased the team’s ability to adapt to high-risk environments and deliver reliable, compliant solutions. With enhanced safety features, improved system visibility, and scalable support mechanisms now in place, ENQUEST benefits from a robust, future-ready control system tailored to meet the demands of hazardous offshore operations. This collaboration not only strengthens Ultech Engineering’s portfolio in the oil and gas industry but also reinforces its commitment to safety, innovation, and client satisfaction.

Watch This Content On YouTube!