The evolving landscape of industries operating in potentially explosive atmospheres demands a robust training and certification program that equips workers with the necessary skills and knowledge to install, maintain, test, repair, and audit electrical and instrument installations. The IECEx Training & Certification Program has emerged as a comprehensive solution, tailored to the specific needs of professionals working in environments where explosive atmospheres pose inherent risks.

This course delves into the explosion-protection aspects associated with installing explosion-protected equipment and wiring systems. Participants will develop the ability to match equipment specifications with designated locations, work safely, adhere to installation standards, and complete essential installation documentation. Moreover, the program extends beyond installation practices, encompassing the critical skills required for evaluating the completeness of hazardous area verification dossiers and ensuring compliance with explosion-protected aspects through visual or close inspections.

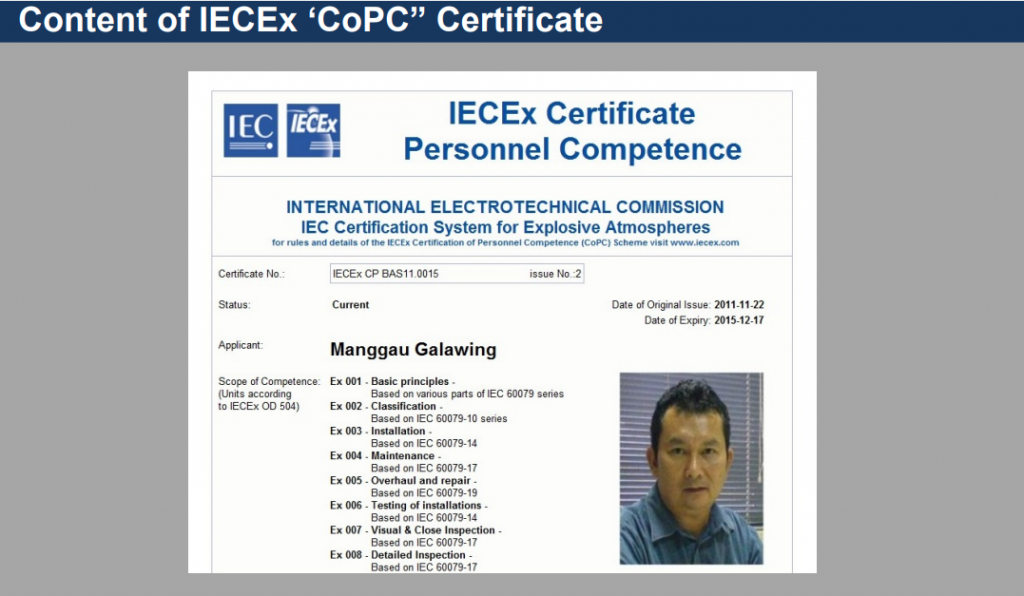

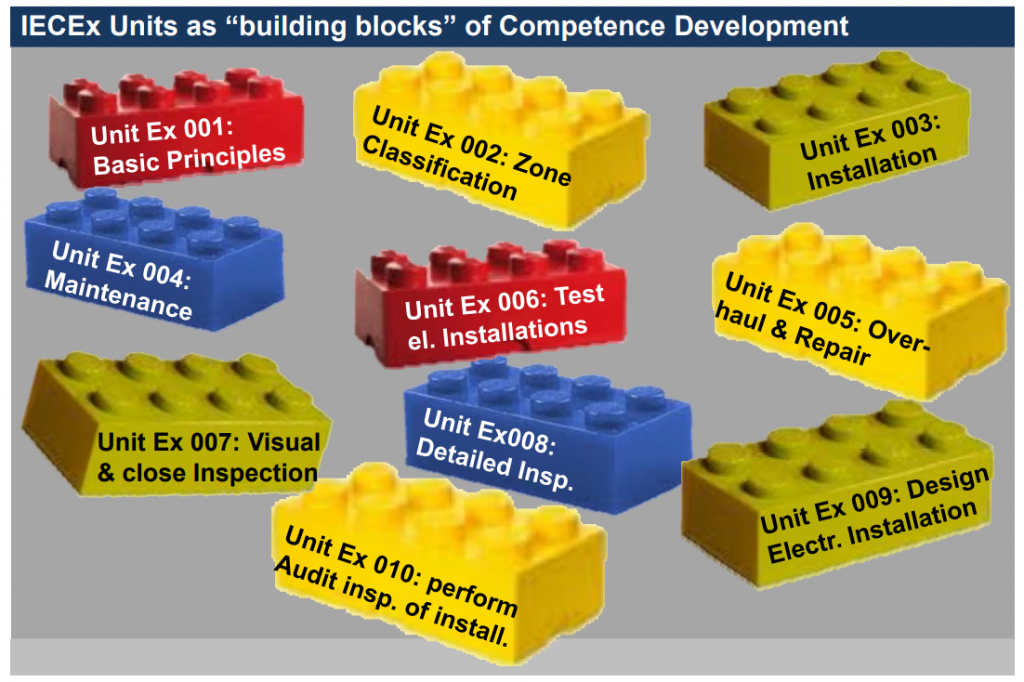

The IECEx Training & Certification Program aims to equip participants with a thorough understanding of the IECEx scheme and services offered, industry developments, and the essential requirements for working in hazardous areas. Attendees will learn to identify and classify hazardous areas, interpret equipment specifications, and apply Ex methodology, design characteristics, zoning, installation, maintenance, and inspection criteria for Ex installations.

Inspectors learn to navigate Ex certification schemes in the context of maintaining equipment. For instance, they might examine a maintenance plan for explosion-protected electrical equipment in a Zone 1 area, ensuring that the equipment complies with ATEX or IECEx standards. This includes understanding the frequency of inspections, documentation requirements, and the importance of certified replacement parts.

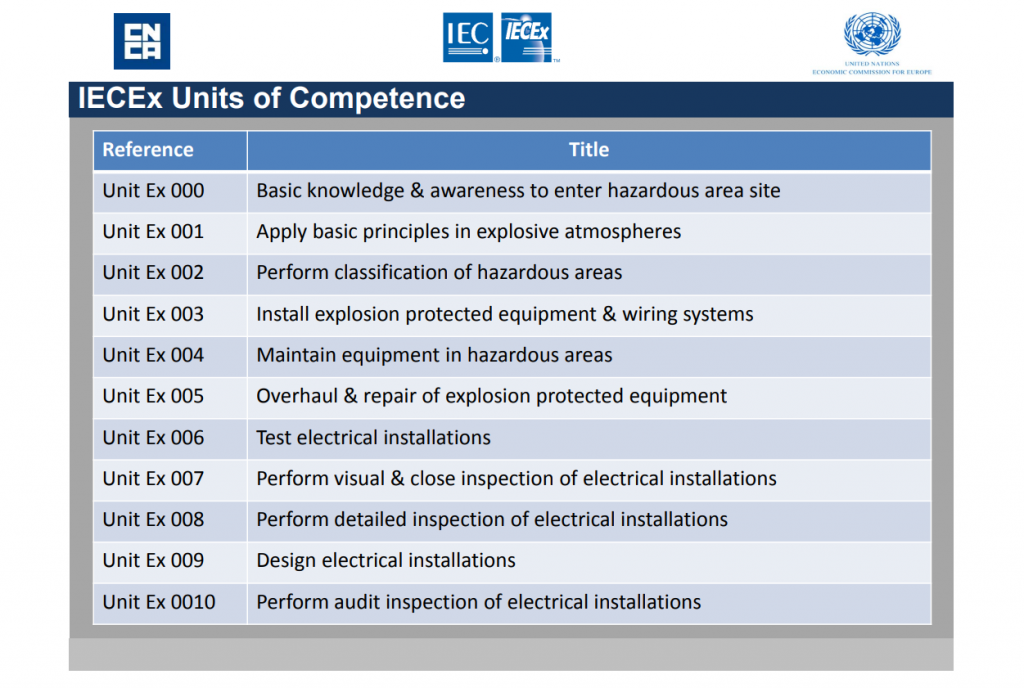

The program spans five days of intensive training, including theoretical classes, practical sessions, case studies, discussions, and assessments. The course covers an array of topics, from the basics of hazardous area classification to the nuances of various protection techniques and installation practices. Special emphasis is given to maintenance of equipment (Ex004 Unit), visual and close inspections (Ex007 Unit) and detailed inspections for electrical and instrumentation equipment (Ex008 Unit).

Participants can expect a dynamic learning experience that combines theory classes with practical applications, case studies, discussions, and assessments. The training duration is five days, followed by a two-day examination conducted in collaboration with our examination partner.

This program is tailored for a diverse range of professionals, including managers, engineers, supervisors, inspectors, technicians, QA/QC personnel, and individuals involved in the installation and maintenance of electrical and instrumentation equipment. Health, safety, and environmental officers will also find this training valuable in enhancing their expertise in managing operations in potentially explosive atmospheres.

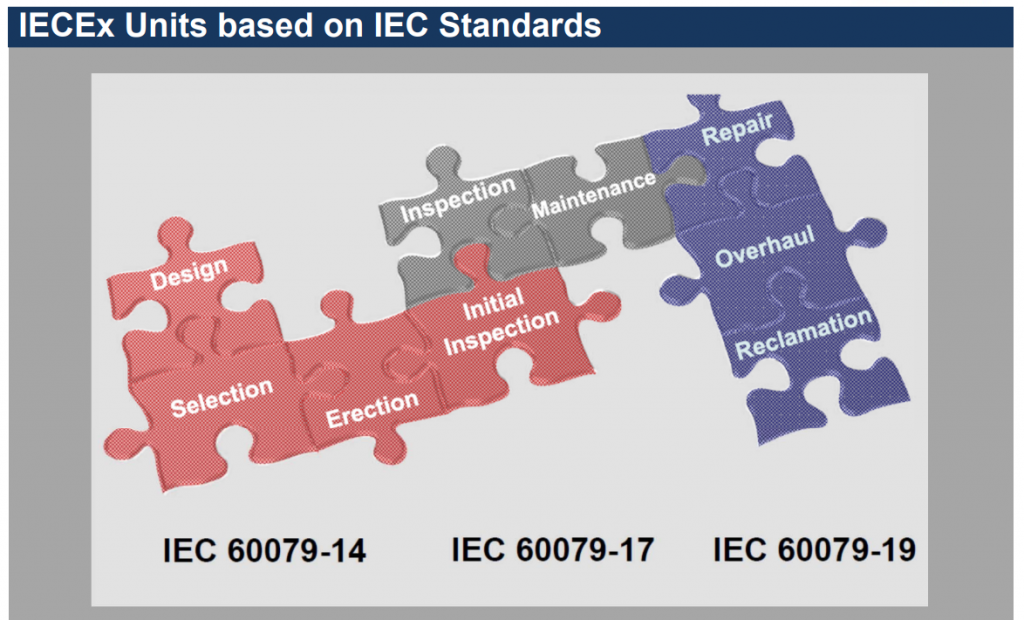

Ex004 Unit covers the explosion-protection aspects related to the maintenance of explosion-protected equipment and associated wiring systems. This includes the development and management of maintenance programs, incorporating strategies for inspections, repair, overhaul, replacement of components, and recording of maintenance outcomes. The competence required extends to working safely, adhering to standards and manufacturer's instructions, and completing necessary maintenance documentation. The unit is based on the guidelines provided by IEC 60079-17 and other relevant standards applicable to explosive atmospheres.

Competence in Ex004 Unit is evaluated through rigorous theoretical tests, consisting of Selected Response and Constructed Response questions. The duration of the knowledge test is determined based on the following time allocations:

The assessment includes various clauses from OD504, with a specific breakdown of assessment time for each clause. Practical assessments, including those for Clause 5.26 and 5.29, are incorporated into the overall evaluation process, with a total assessment time of 4 hours and 5 hours 38 minutes, respectively. Importantly, when multiple units are assessed simultaneously, there is no need to repeat questions covered in the assessment of previous units.

Ex007 Unit encompasses the evaluation of the completeness of a hazardous area verification dossier and the compliance of explosion-protected aspects in electrical installations. The competency required involves working safely in hazardous areas, assessing verification dossiers, identifying certified explosion-protected equipment and their specified locations, inspecting installations for compliance, and reporting and acting on inspection results. The unit is founded on standards such as IEC 60079-14 and IEC 60079-17, with consideration given to any other relevant standards.

Competence in Unit EX007 is evaluated through a rigorous theoretical exam consisting of Selected Response and Constructed Response questions. The duration of the knowledge test is based on the following time allocations:

The assessment includes various clauses from OD504, with a specific breakdown of assessment time for each clause. A practical assessment is also incorporated into the evaluation process, with a total assessment time of 4 hours and 4 minutes. Importantly, when multiple units are assessed simultaneously, questions covered in the assessment of previous units need not be repeated.

Ex008 Unit focuses on the explosion-protection aspects of conducting initial, periodic, and sample audit inspections of explosion-protected equipment and installations. The competency required includes auditing verification dossiers, working safely in hazardous areas, inspecting against standards, and effectively reporting and acting on inspection results. The unit is rooted in standards such as IEC 60079-14 and IEC 60079-17, with consideration given to any other relevant standards.

Competence in Ex008 Unit is evaluated through a rigorous theoretical exam consisting of Selected Response and Constructed Response questions. The duration of the knowledge test is based on the following time allocations:

The assessment includes various clauses from OD504, with a specific breakdown of assessment time for each clause. Practical assessments, including those for Clauses 5.37 and 5.39, are incorporated into the evaluation process, with a total assessment time of 4 hours and 6 hours 8 minutes, respectively. Importantly, when multiple units are assessed simultaneously, questions covered in the assessment of previous units need not be repeated.

Applicants for Ex004, Ex007 and Ex008 Unit are required to possess a level of technical education or equivalent, substantiated by documents like college certificates and trade credentials. Operatives should have a minimum of 3 years of experience in general electrical installation practice, while responsible persons must demonstrate a minimum of 3 years of experience in Hazardous Area installation practice. Competence in Ex001 Unit, "Apply Basic Principles of Protection in Explosive Atmospheres," is a prerequisite and may be assessed concurrently or after. Other than that, the pricing of the Ex004, Ex007 and Ex008 would be a fixed price for all three giving a total of RM 7725.00.

In conclusion, the IECEx Training & Certification Program offers a comprehensive solution for professionals working in industries with potentially explosive atmospheres. The five-day program, focusing on three key units – Ex004, Ex007 and Ex008 Units – equips participants with the necessary skills to ensure safety and compliance in hazardous areas. From understanding explosion-protection techniques to conducting visual inspections and detailed audits, the program covers crucial aspects rooted in stringent standards such as IEC 60079-14.

By combining theoretical classes, practical sessions, and assessments, the program provides a dynamic learning experience for a diverse range of professionals, enhancing their expertise in the installation and maintenance of electrical and instrumentation equipment. Ultimately, certified individuals emerge with a thorough understanding of the IECEx scheme and essential industry requirements, contributing to safer operations in explosive atmospheres.

The program is tailored for a diverse range of professionals, including managers, engineers, supervisors, inspectors, technicians, QA/QC personnel, and individuals involved in the installation and maintenance of electrical and instrumentation equipment. Health, safety, and environmental officers will also find this training valuable in enhancing their expertise in managing operations in potentially explosive atmospheres.

Applicants for Unit EX007 are required to have a certain level of technical education or equivalent, supported by documents such as college certificates and trade credentials. Operatives need a minimum of 3 years of experience in industrial electrical installation practice, while responsible persons must have a minimum of 3 years of experience in Ex electrical installation practice relevant to the unit's scope. Competence in Unit EX001, "Apply Basic Principles of Protection in Explosive Atmospheres," is a prerequisite and may be assessed concurrently or after.

Competence in Unit EX008 is evaluated through a rigorous theoretical exam consisting of Selected Response and Constructed Response questions. The duration of the knowledge test is based on specific time allocations for different types of questions. Practical assessments, including those for Clauses 5.37 and 5.39, are incorporated into the evaluation process, with a total assessment time of 4 hours and 6 hours 8 minutes, respectively. Importantly, when multiple units are assessed simultaneously, questions covered in the assessment of previous units need not be repeated.