In the world of industrial electrical installations, where precision, safety, and durability are paramount, even the smallest components can make the biggest difference. Among these, the act of crimping — joining conductors and terminals into a reliable electrical bond — plays a fundamental role. A perfect crimp ensures that connections remain mechanically sound, electrically conductive, and resilient against vibrations, corrosion, or thermal expansion. However, the quality of a crimp is only as good as the tool used to make it. This is where Weidmüller, a globally respected name in electrical connectivity, sets a new standard with its exceptional range of crimping tools.

In industrial electrical installations, crimping quality is far more than a technical detail — it’s a safeguard for the entire system. A poor crimp can compromise safety, causing connection failures, increased resistance, overheating, and even electrical fires. By contrast, a high-quality crimp ensures optimal conductivity, strong mechanical retention, and consistent long-term performance. This reliability is especially crucial in industrial settings, where unexpected downtime can quickly escalate into significant costs. With Weidmüller’s precision-engineered tools, crimp quality is never left to chance — every termination meets exacting standards, protecting both equipment and personnel.

Beyond safety and performance, crimp connections offer distinct advantages that make them the preferred choice across industries. They enable efficient production at any scale, from small manual assemblies to high-volume automated lines, delivering secure and repeatable results whether made by fully automatic machines, semi-automatic equipment, or hand tools. Unlike soldered joints, crimps avoid issues such as cold solder points, heat damage to insulation, or altered spring characteristics in contacts. The conductor remains flexible behind the crimp, insulation integrity is preserved, and both mechanical strength and electrical performance are maintained over time. Together, these qualities make crimp connections a dependable, high-performance solution for modern electrical installations.

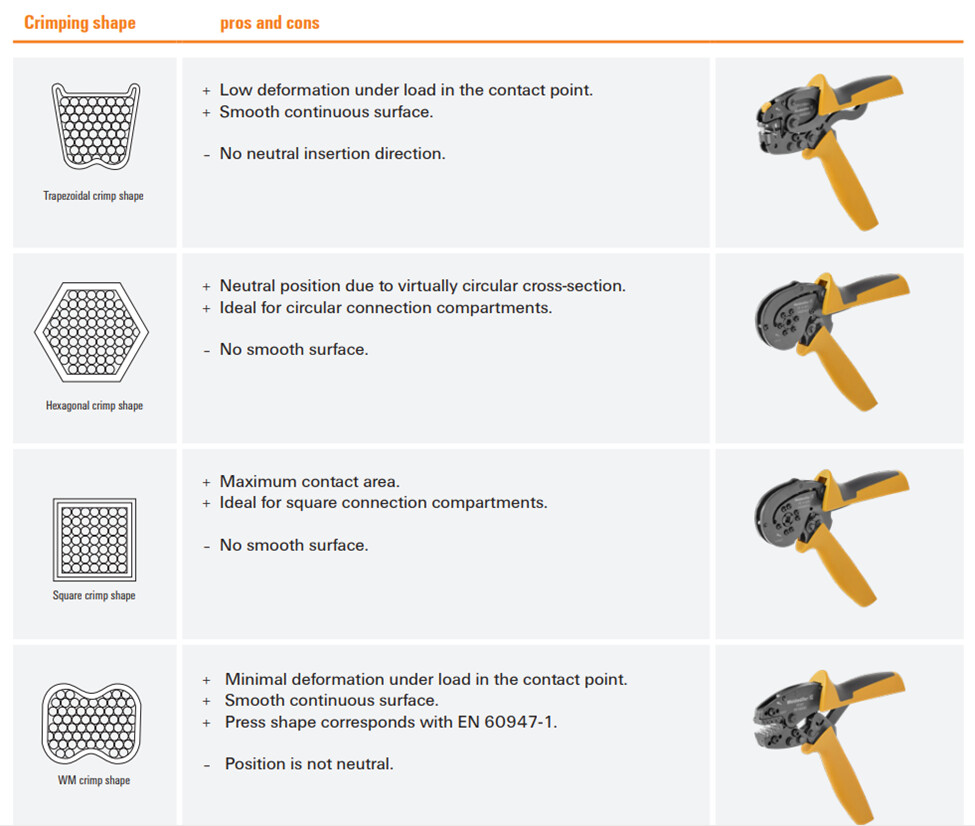

In the world of crimping, the choice of press shape is not a one-size-fits-all decision. A wide variety of press shapes is available on the market for crimping wire-end ferrules, and selecting the right one depends on the specific requirements of the application. Each shape offers its own set of strengths and trade-offs, and understanding these characteristics helps ensure the most reliable and durable connection for the task at hand.

The trapezoidal crimp shape is a popular choice for many industrial applications. It offers low deformation under load at the contact point, meaning the integrity of the connection is well maintained even under mechanical or thermal stress. The smooth and continuous surface finish also helps ensure consistent electrical performance. However, one limitation is that it does not offer a neutral insertion direction, meaning positioning becomes more critical during the crimping process.

The hexagonal crimp shape, with its virtually circular cross-section, provides a neutral positioning advantage — an important benefit when working with circular connection compartments. This shape is ideal when the installation environment demands flexibility in connector orientation. However, it lacks the smooth surface finish of the trapezoidal shape, which may be a consideration in certain electrical or environmental conditions.

The square crimp shape maximises the contact area between conductor and ferrule, resulting in excellent electrical conductivity. It is particularly well-suited for square connection compartments, ensuring a secure mechanical fit. Like the hexagonal shape, however, it does not feature a completely smooth surface.

Finally, the WM crimp shape, developed under EN 60947-1, offers a balance of advantages. It delivers minimal deformation under load, a smooth, continuous surface, and compliance with recognised international standards. Its main trade-off is that, like the trapezoidal crimp, it does not provide a neutral insertion direction. Still, for many engineers and technicians, the WM shape represents an ideal compromise between performance, compliance, and connection quality.

By offering a coordinated system that supports all these press shapes, Weidmüller ensures that users can select the most appropriate crimping method for their specific application — maximising both mechanical durability and electrical performance.

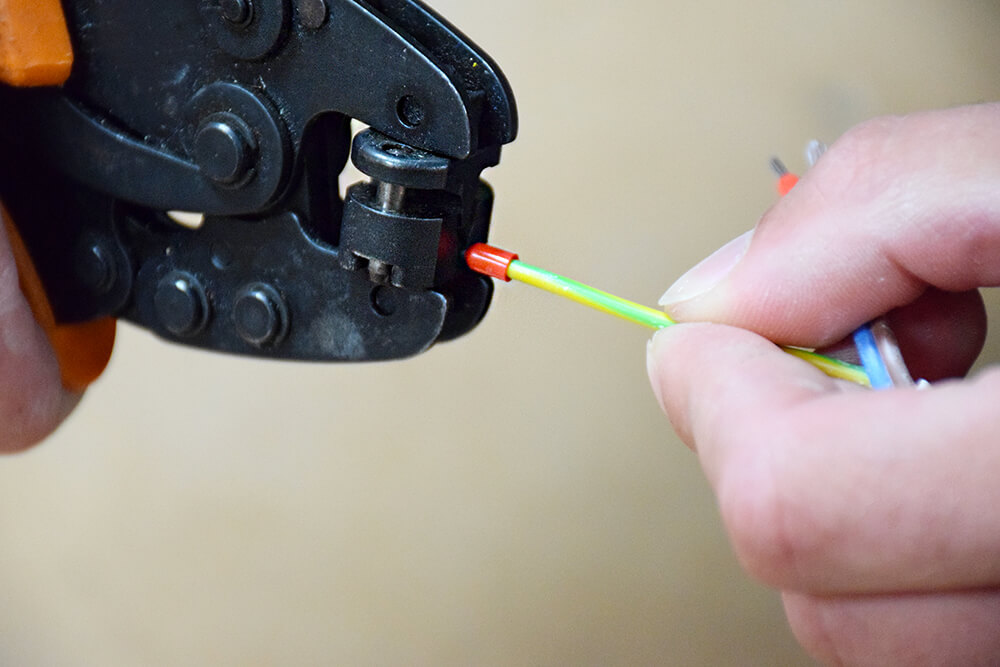

However, even the best tools can be misused without proper knowledge of crimping techniques. Poor practices in cable preparation and termination can undermine the integrity of an otherwise well-engineered system. It all begins with cutting the conductor. A clean, right-angled, and crush-free cut provides the best foundation for a secure crimp. If the wire is distorted or improperly cut, it becomes difficult to insert fully into the ferrule or terminal, resulting in a weak or incomplete crimp.

Next, insulation must be stripped carefully to expose the conductor without damaging or nicking the strands. The exact length of insulation to be removed varies depending on the ferrule or terminal type, but precision here is critical. Stripping too much or too little can compromise the electrical contact or cause exposed conductors to short against neighbouring components. Once stripped, the conductor should be inserted into a wire-end ferrule or terminal such that 1 to 2 millimetres of the conductor slightly protrude beyond the copper tube. This ensures maximum electrical contact while verifying correct insertion depth.

Mistakes to avoid during crimping include applying force unevenly, which can result in asymmetrical compression or burr formation on one side of the ferrule. Other common errors include splitting the ferrule walls due to excessive pressure, crushing the conductor strands until they break, or accidentally pushing strands backwards out of the ferrule. These defects not only reduce the mechanical strength of the crimp but can also cause heat buildup, signal interference, or complete failure under load.

Unlike generic alternatives, Weidmüller’s crimping tools are built for professionals who cannot afford to compromise. The range is designed with ergonomics, reliability, and long-term usability in mind. For installers and technicians who work with a wide variety of conductor types and terminal sizes, Weidmüller offers a carefully curated selection of mechanical and electro-hydraulic crimpers tailored to suit every situation. Whether it's compact ferrule crimping or heavy-duty lug connections, Weidmüller ensures you always have the right tool in hand.

One of the defining features of Weidmüller crimping tools is their precision engineering, particularly the integration of universal crimp dies with automatic spring compensation. This technology allows the tool to adjust dynamically to the size and shape of the ferrule or contact being crimped. As a result, users can achieve consistently high-quality crimps without needing to manually calibrate or worry about inconsistencies. This not only prevents user error but also significantly reduces the learning curve for new operators.

Equally important is the ergonomic design philosophy that guides the development of every Weidmüller tool. The internal mechanics are carefully balanced to minimise the physical force required during operation, reducing hand fatigue over long shifts. By incorporating refined geometries and smooth actuation paths, these tools make repetitive crimping tasks easier and less strenuous. The result is improved worker comfort, increased productivity, and a reduction in repetitive strain injuries.

Durability is another hallmark of Weidmüller’s engineering. Each tool is built from high-grade materials, manufactured with precision tolerances, and rigorously tested for endurance under industrial conditions. This high standard ensures that Weidmüller tools remain accurate and reliable even after years of continuous use. In environments where tool performance can directly impact job quality and safety, that level of dependability is invaluable.

A notable innovation from Weidmüller is the PZ 2.5 crimping tool, which has quickly become a favourite among electrical professionals for its compact design and outstanding performance. Engineered specifically for wire-end ferrules ranging from 0.14 to 2.5 mm², the PZ 2.5 is the smallest professional-grade crimping tool in its class. It was developed with a focus on compactness without sacrificing crimp quality — a combination rarely achieved in such tools.

One of the most impressive aspects of the PZ 2.5 is its handling. The handle width, jaw opening angle, and overall weight have each been reduced by approximately 30% compared to traditional crimpers. This makes the tool not only more comfortable to use but also highly manoeuvrable in tight spaces, such as control panels or field service environments where accessibility is limited. Despite its size, the PZ 2.5 delivers a robust trapezoidal crimp that fully complies with global safety and performance standards. It's universal die further reduces the risk of misalignment or incorrect insertion, ensuring a foolproof operation for users at any skill level.

Durability is another area where the PZ 2.5 excels. By focusing specifically on small cross-sections, Weidmüller has minimised wear on the internal components, effectively doubling the tool's service life. In long-term usage tests, the PZ 2.5 maintained consistent performance with virtually no degradation in crimp quality — a testament to Weidmüller’s commitment to long-lasting tools.

Complementing the PZ 2.5 are other standout solutions like the new Stripax Plus, a multifunctional tool that combines cutting, stripping, and crimping into a single device. This all-in-one design is particularly useful for field technicians and electricians who need to work quickly and efficiently with limited space and tool availability. With automatic feeding of Weidmüller linked wire end ferrules (50 pieces per strip), a ratchet mechanism for precise crimps, and a release option for incorrect operation, the Stripax Plus ensures consistent results every time.

The entire cable preparation process can be completed in just a few seconds, dramatically reducing installation time without compromising quality. For best performance, only strips of linked Weidmüller wire end ferrules should be used, as ferrules on reels may cause damage.

In response to the need for enhanced flexibility in cramped enclosures, Weidmüller introduced the PZ 6 ROTO ADJ — a revolutionary crimping tool featuring a rotating die and adjustable handle width. This design enables installers to adjust the tool’s orientation to suit the work environment, providing improved access in tight corners or awkward angles. In high-density control cabinets, this flexibility becomes a major productivity booster, enabling technicians to crimp wire end ferrules — with or without plastic collars — precisely and consistently. A built-in ratchet mechanism ensures every crimp meets the correct specification, while a release function offers added safety in the event of incorrect operation.

Weidmüller’s commitment to versatility is also evident in its extensive product portfolio. The range includes crimping tools for wire-end ferrules up to 50 mm², insulated connectors from 0.5 to 6 mm², and non-insulated contacts up to 25 mm². For heavy-duty applications, Weidmüller offers both mechanical and electro-hydraulic solutions capable of handling conductor sizes up to 400 mm². Tools are also available for coaxial connectors, such as BNC and TNC, as well as modular plugs like RJ12 and RJ45, and speciality contacts for industrial interfaces, including SUB-D, ConCept, and HD/HE series.

Additionally, Weidmüller addresses the needs of specific markets by offering tools for photovoltaic connectors, fibre-optic terminations, and flat cable lugs. This diversity ensures that engineers, electricians, and even students in vocational training programs can find a Weidmüller tool suited to their application. For those seeking portability and convenience, multifunction tools that combine cutting, stripping, and crimping remain a popular choice.

Ultech Engineering, as an authorised distributor of Weidmüller products in Malaysia, has long shared the brand’s commitment to precision, innovation, and reliability. Weidmüller, founded in Germany in 1850, has a proud heritage in industrial connectivity and automation solutions. Its reputation for engineering excellence has made it a trusted name worldwide. This partnership between Ultech and Weidmüller is more than just a distributor-supplier relationship — it is a collaboration designed to deliver the very best tools, components, and solutions to engineers, technicians, and industries across the region.

Since becoming an authorised distributor, Ultech has consistently worked to bring Weidmüller’s cutting-edge products, such as their precision crimping tools, closer to local markets. This commitment was seen during last year’s DEIF genset controller training, where Ultech showcased Weidmüller’s crimping tools, allowing participants to experience their ease of use and consistent quality firsthand.

In 2025, the partnership takes another step forward with a strong presence at OGA (Oil & Gas Asia), where Weidmüller’s tools are featured as part of an exclusive Tools Bundle Set Promo. This bundle set consists of three different crimping tools — the CTI 6, PZ 6 ROTO L, and STRIPAX — and each crimping tool set comes with its own tool bag, along with a slotted screwdriver, a crosshead screwdriver, and a voltage tester. This initiative not only offers value to customers but also reinforces the shared goal of both companies: empowering professionals with the right tools to work more efficiently and reliably, regardless of the application's demands.

In industrial electrical work, precision is not optional — it is the foundation of safety, performance, and reliability. Every crimp, no matter how small, plays a critical role in ensuring systems operate without interruption, even in the most demanding environments. Weidmüller’s crimping tools embody this philosophy, combining engineering excellence, ergonomic design, and long-lasting durability to deliver results professionals can trust. From compact, agile solutions like the PZ 2.5 to multifunctional innovations like the Stripax Plus and adaptable designs such as the PZ 6 ROTO ADJ, each tool is crafted to make every connection perfect, every time.

Through Ultech Engineering’s partnership with Weidmüller, this level of precision and reliability is now more accessible than ever to industries across Malaysia. Whether in control panels, heavy-duty connectors, or renewable energy projects, Weidmüller crimping tools empower engineers and technicians to work faster, safer, and with complete confidence. In a field where every connection counts, choosing the right tool is not just a matter of convenience — it’s a commitment to excellence.