In industries where safety is paramount, professionals must possess the right knowledge and skills to navigate hazardous environments confidently. The International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres (IECEx) Certification of Personnel Competence (CoPC) stands as a beacon of excellence, transforming careers and ensuring the highest standards of safety.

IECEx CoPC certification serves as the bedrock for professionals working in or around explosive atmospheres. Whether it's designing, installing, operating, inspecting, or maintaining electrical installations in hazardous environments, this certification is a testament to an individual's proficiency in ensuring safety in potentially explosive environments.

Professionals undergoing IECEx CoPC certification gain a profound understanding of the fundamental principles of protection in explosive atmospheres. The certification journey involves in-depth training on relevant standards, emphasizing the importance of safety obligations, limitations on devices, and occupational health and safety responsibilities related to hazardous areas.

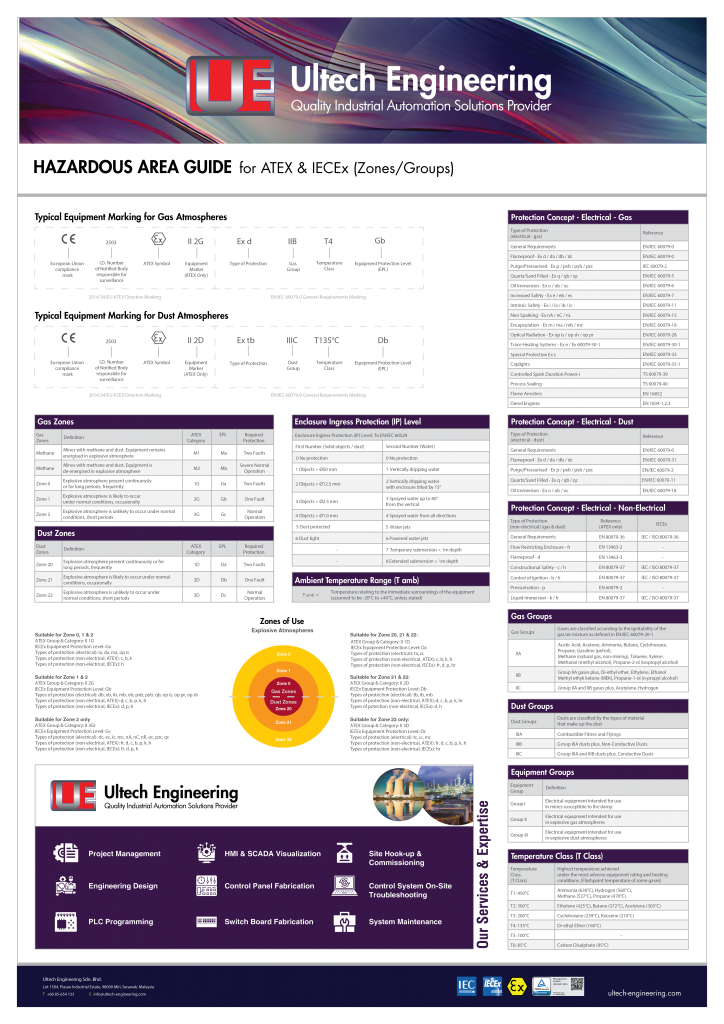

Intrinsically safe is a term used to describe a collection of devices and equipment that meet the requirements set out by the certification body (ATEX, UL or IECEx) to determine that device or equipment’s safety when used in a hazardous environment.

A Hazardous Environment is an area where fumes, dust, gas or vapour may cause a fire or explosion when an ignition source is used in the area. For example, you may see a ‘No Naked Flames’ sign in your petrol station when filling up your car, this is because the area is classed as a Hazardous Environment. People who use devices like Two-Way Radios in these environments need to ensure that the device itself complies with the standard set for that particular zone. Often a safety officer will have this information to hand and be able to direct you as to what type of equipment you need for different areas of your plant.

What is explosion-proof? The National Fire Protection Association, or NFPA, set in place a list of standards regarding the safe installation of electrical wiring and equipment. These standards must be strictly followed when designing products for use in any hazardous applications. All components installed in hazardous environments will have to meet the criteria set by these definitions to ensure the safety of the plant and the personnel.

IECEx International Certification is the way to safety compliance in hazardous areas as IECEx certifies the skills, knowledge and competence of persons working in Ex areas. IECEx certifies the skills, knowledge and competence of persons working in Ex areas.

The increasing application of industrial automation in hazardous areas has improved the efficiency and safety of installations. On the other hand it may also have increased the risk of fire or explosion hazards.

These hazardous areas include places where flammable liquids, vapours, gases or combustible dusts could present a fire or explosion hazard. They are also called “Hazardous Locations,” “Explosive Atmospheres” or “Ex Areas”.

Equipment, especially electrical, and their use in these areas are covered by a wide range of IEC Standards and are generally highly regulated.

It is in the interest of industry and governments to ensure that Ex Areas and the personnel working in them are as safe as possible for those personnel, the community and the environment.

The IECEx System is supported by three Conformity Assessment Schemes, which, over the years, have established a high level of confidence in those manufacturing, operating and maintaining equipment, installations and systems in compliance with IEC International Standards:

Ex equipment – IECEx certification assures that the strictest safety requirements of IEC International Standards, as referenced in many national or regional compliance programmes, are met, e.g. ATEX.

Repair/overhaul: Assesses and certifies that organizations and workshops that provide Ex equipment selection, design, installation, inspection, maintenance, repair, overhaul and reclamation services to the Ex industry do so respecting the strict requirements of IEC International Stand- ards IEC 60079-14, IEC 60079-17 and IEC 60079-19.

Personnel: The IECEx Certification of Personnel Competence provides assurance to those engaging or dealing with IECEx-certified persons that their knowledge and competence has been independently verified.

The difference between these three is the testing/classification body.

Each rating is created by a recognised standards body with ATEX Being European, UL being American and IECEx often used for international standards.

ATEX and IECEx may seem similar, but there are some important differences between the two certifications that you should know. To protect the health and safety of your employees, you should be clear on the different requirements that each certification entails. Even though ATEX and IECEx are common terms in the industry, many of us might still be confused on what they stand for.

ATEX is derived from the term ‘ATmosphere EXplosibles’ and it is a mandatory certification for all products to be sold across Europe. ATEX consists of two European Directives that mandate the type of equipment and work conditions allowed in a hazardous environment.

The ATEX 2014/34/EC Directive, also known as ATEX 95, applies to the manufacture of all equipment and products that are used in potentially explosive environments. The ATEX 95 Directive states the basic health and safety requirements that all explosion proof equipment and safety products have to meet in order to be traded in Europe.

The ATEX 99/92/EC Directive, also known as ATEX 137, is aimed at protecting the health and safety of employees who are constantly exposed to potentially explosive working environments. The directive states:

UL is classified by Divisions and Classes. The classes define the substance whilst the Division defines the operating conditions. The classes are also split into subgroups to determine specific and/or equivalent substances.

Division 1 – Locations where ignitable gas/vapor/liquid/dust are present continuously or some of the time under normal operating conditions.

Division 2 – Locations where ignitable gas/vapor/liquid/dust are not likely to exist under normal operating conditions.

Based on the above a rating of ‘Class I, Div 1, Group C, D’ would be given to an environment where Ethylene and Methane are expected to be present continuously

IECEx is very similar to ATEX however some of the definitions for the protection offered do differ so keep that in mind. IECEx stands for the certification by the International Electrotechnical Commission for Explosive Atmospheres. To be IECEx certified, all products must go through a monitored process by the International Electrotechnical Commission to ensure that they meet the minimum safety requirements. This process will determine if the products can be used in hazardous or potentially explosive locations.

Being IECEx certified allows the products and equipment to be traded across countries without having to be re-tested and re-certified for every country. As different countries adhere to different safety standards, products from one country have to be re-tested in another country to abide by its guidelines for use in hazardous areas. Therefore, IECEx acts as a common set of safety standards amongst participating countries' certification which helps to reduce testing and certification costs for manufacturers. Participating countries in the IECEx Scheme include the majority of countries in Europe, Canada, Australia, Russia, China, United States and South Africa.

The main difference between ATEX and IECEx is that ATEX certification only applies to countries in the EU while IECEx certification is accepted globally. Hence, the IECEx certification is more widely recognised and accepted compared to ATEX certification.

Another key difference between ATEX and IECEx certifications is that ATEX is law-driven while IECEx is standard-driven. The manufacturer is accountable for the entire ATEX certification process for products. On the other hand, the responsibility lies with the external certification party to ensure that the necessary products are IECEx-certified.

One fundamental way that ATEX differs from IECEx is the way each certification is set up. The IECEx certification consists of four schemes: IECEx Equipment Scheme, IECEx Conformity Mark License, IECEx Services Scheme, and IECEx Certified Persons Scheme. These four schemes are to ensure that every aspect of the products conforms to the IECEx standard, from the quality of the Ex equipment itself to the competency of the personnel who will be handling such equipment in hazardous environments. On the other hand, the ATEX certification only consists of 2 directives: ATEX 95 and ATEX 137.

Furthermore, ATEX certification can be based on an IECEx test report, but an ATEX documentation may not necessarily support an IECEx certificate. Therefore, it has become a common industry requirement for products to contain both ATEX and IECEx certificates.

The IECEx System is the only Certification scheme to be formally endorsed by the United Nations as the “world's best practice and recommended model” for use by regulators when regulating the use of Ex equipment and Services. The use of the IECEx Conformity Assessment System and its Schemes provides clear advantages for industry and governments:

The IECEx System comprises the following Schemes for which all Certificates, Reports, supporting documentation and Certification Body details, as well as rules, operational documents, procedures and a list of the IECEx Certification Bodies, are available online at www.iecex.com.

Ultech is offering the IECEx CoPC Certification Preparatory Courses with Assessment locally in Sabah and Sarawak in partnership with Capeserve Energy and its certification body from Norway, Exert Certification. That means that our certificate provides training for individuals intending to work in a hazardous area and is separate from the IECEx certification for equipment and service facilities. For the sake of focus, the IECEx Certification will refer to the IECEx CoPC certification scheme from here onwards.

IECEx Certification of Personnel Competence Scheme provides independent verification that a person holding an IECEx CoPC (Certificate of Personnel Competence) can apply his/her skills, knowledge, qualifications and experience to work safely following relevant International Ex Standards. This can be especially important for contracting staff.

To obtain an IECEx Certificate of Personnel Competence, a person prepares an application and submits it to an approved IECEx Certification Body. The person will undergo knowledge tests and an assessment of qualifications and experience before receiving an IECEx Certificate. Regular re-assessment ensures that the certified person maintains his/her competencies and currency of knowledge with the relevant Standards as updated from time to time. The IECEx CoPC is personal, non-transferable and valid across international borders. As well as the certificate itself, the person obtains an identification card with a photo, providing instant proof of certification. As with all IECEx Certificates, this is valid across international borders.

The certification process is divided into units of competence, each focusing on specific aspects of working in hazardous areas. From basic knowledge (EX 000) and principles of protection (EX 001) to classification of hazardous areas (EX 002) and installation and testing of explosion-protected equipment (EX 003 & 006), the certification covers a comprehensive range of skills.

For inspection personnel, the certification encompasses maintaining equipment in explosive atmospheres (EX 004), performing visual and close inspections (EX 007), and conducting detailed inspections (EX 008). This trifecta of competence ensures that individuals are not only capable of installing equipment but are also adept at ensuring its ongoing safety.

The certification journey culminates in the EX 009 unit, focusing on designing electrical installations in or associated with explosive atmospheres. Professionals completing this unit demonstrate a high level of expertise, contributing to the creation of safe and efficient electrical systems in hazardous environments.

IECEx CoPC certification is not just a badge; it's a commitment to safety and excellence. Professionals armed with this certification bring a higher level of competence to their roles, reducing the risk of accidents and ensuring the safety of both personnel and equipment.

Countless professionals have experienced transformative career shifts after obtaining IECEx CoPC certification. Industries value this certification as a mark of distinction, opening doors to new opportunities and career advancements. The stories of these professionals stand as a testament to the life-changing impact of IECEx CoPC certification.

In conclusion, IECEx CoPC certification is a powerful catalyst for career transformation in hazardous environments. Beyond theoretical knowledge, it instils a culture of safety, making professionals invaluable assets in industries where precision and competence can mean the difference between a routine operation and a potential catastrophe.