Ultech Engineering is proud to announce its return to Oil & Gas Asia (OGA) 2025, continuing our presence at Southeast Asia’s most prominent oil, gas, and energy trade event. Following successful participations in both 2023 and 2024, Ultech is once again set to deliver cutting-edge automation and power system solutions to the heart of Malaysia’s energy industry.

Over the past two years, OGA has served as a pivotal platform for Ultech to connect with industry leaders, exchange technical know-how, and showcase innovative technologies that are transforming the industrial landscape. From live demos to hands-on discussions, our booths have consistently drawn engineers, decision-makers, and partners seeking reliable, forward-thinking solutions.

Founded in 2011 and officially incorporated in 2014, Ultech Engineering has grown from a local system integrator into one of East Malaysia’s most trusted names in industrial automation, power systems, and hazardous area control solutions. Based in Miri, Sarawak, we specialise in delivering end-to-end engineering services — from feasibility studies and design, to commissioning and lifecycle support.

Our portfolio spans a wide range of industries, including oil & gas, marine, palm oil, utilities, and manufacturing. With a firm commitment to quality, safety, and innovation, Ultech is a registered vendor with PETRONAS and a recognised integration partner for global automation leaders.

At OGA 2025, Ultech Engineering will showcase a suite of intelligent industrial solutions centred around real-world applications and trusted global technology partnerships. This year’s lineup focuses on critical automation and power control systems that highlight Ultech's core capabilities since 2014, which are primarily designed for harsh environments and mission-critical performance.

Featuring the industrial-grade iE350 controller and the modular AGC 150 genset controller series, Ultech will demonstrate how DEIF’s technologies enable intelligent power orchestration, scalable control architectures, and secure, automation-ready solutions for critical energy systems.

Highlighting our application of the Allen-Bradley CompactLogix PLC in firewater pump systems, designed for instant activation, run-until-fail logic, and high-reliability operation in offshore safety systems.

Showcasing the powerful MELSEC iQ-R Series, applied in superheater control systems for offshore gas engines, offering precise thyristor modulation, PID temperature control, and fail-safe heating logic for moisture removal in fuel supply lines.

Showcasing a focused selection of Ex-certified solutions, including stainless steel and polyester Klippon® enclosures, a preassembled local control station with emergency stop, Ex-rated cable glands and blanking plugs, and the KCSL KEBx control station, all designed for hazardous zones. As for Cabex’s Ex E1FU-HT cable glands, they are designed for high-temperature and hazardous environments. These glands provide secure cable terminations, environmental sealing, and mechanical resilience, ensuring reliable performance in offshore and industrial instrumentation systems.

Serving as the central monitoring layer, GENESIS64™ unifies data from DEIF, Rockwell, and Mitsubishi controllers into one secure, real-time interface. It enables local and remote visibility for power, heating, and safety systems—all through a scalable, web-enabled platform.

At this year’s event, visitors can expect interactive displays, live product demos, and firsthand insights into how our solutions enhance safety, efficiency, and digital transformation across critical industries.

One of the highlights of Ultech’s OGA 2025 showcase is our intelligent power control lineup from DEIF, a trusted partner in marine and industrial automation. DEIF’s solutions form the foundation of many of Ultech’s most mission-critical projects, where uptime, resiliency, and flexibility are non-negotiable.

At Ultech Engineering, smart power management starts with precision control and seamless synchronisation — and that’s exactly what the DEIF AGC 150 series delivers.

At OGA 2025, our demo highlights three AGC 150 genset controllers working in parallel to form a highly reliable and scalable power management system. These controllers demonstrate advanced capabilities in synchronisation, protection, load sharing, and monitoring, whether for standalone gensets, parallel configurations, or hybrid setups.

Thanks to CAN bus auto-detection, newly added gensets are recognised instantly, streamlining commissioning and reducing engineering effort. Combined with multi-level user access, sunlight-readable displays, and robust design, the AGC 150 becomes an essential control solution for both temporary and permanent power installations.

Key variants include:

The iE350 is featured at the Ultech booth as a dedicated product highlight, offering visitors a closer look at DEIF’s advanced automation capabilities beyond the main power management systems on display.

Built on a secure Linux platform, the iE350 is a highly configurable and durable intelligent controller designed for marine and industrial power applications. It features built-in support for IEC 61131-3 programming via DEIF’s proprietary PICUS software, with optional CODESYS PLC functionality available for extended control logic. The iE350 offers modular rack expansions, secure remote updates, and robust cybersecurity features, including SSH, SCP, and signed firmware, compliant with IEC 62443 standards. With a -40 °C cold start capability and 50G shock resistance, the iE350 delivers long-term reliability in harsh and mission-critical environments. At OGA 2025, the iE350 is featured as a standalone showcase to highlight DEIF’s scalable automation and power control solutions.

At OGA 2025, Ultech Engineering demonstrates that modern power management goes far beyond backup — it’s about intelligent orchestration, resilience, and control at every level. With the AGC 150 forming a modular, responsive backbone for critical power systems, and the iE350 showcasing the next generation of industrial-grade controllers, our booth presents a clear vision of how Ultech engineers smart, scalable, and secure energy solutions. Together with DEIF, we’re powering reliability where it matters most — from genset synchronisation to advanced industrial integration.

Additionally, Ultech Engineering highlights our expertise in critical safety automation, featuring Rockwell Automation’s Allen-Bradley CompactLogix Programmable Automation Controller (PAC) — the brain behind high-stakes systems, such as fire water pumps (FWP), deployed on offshore platforms and industrial facilities.

Allen-Bradley CompactLogix programmable automation controllers provide a flexible and powerful automation platform designed for small to mid-sized applications that require fast response times, high reliability, and seamless integration. Part of Rockwell Automation’s Logix platform, CompactLogix shares the same control engine and Studio 5000 development environment as its larger sibling, ControlLogix, allowing for consistent logic design and code reuse across system scales.

With support for motion, process, discrete, and safety control in one controller, CompactLogix delivers a unified solution with modular scalability. The latest models (such as the 5380 and 5480 series) bring faster processing, larger memory, and built-in cybersecurity features like controller locking, role-based access control, and firmware signature verification.

Based on the features of the CompactLogix 5380 Process Controller — including high-speed processing, expanded memory, and native EtherNet/IP support — the system offers tight integration with the PlantPAx 5.0 distributed control platform, significantly reducing the need to import Add-On Instructions. It also enables users to subscribe to real-time diagnostic information directly through FactoryTalk View Site Edition, without requiring extra programming. With support for up to 32 axes of integrated motion and seamless compatibility with Compact 5000™ I/O modules, the 5380 delivers a scalable, high-performance solution fit for a wide range of industrial automation needs. Therefore, this integration can be doable for Ultech due to its seamless integration and its compatibility with the CompactLogix 5000 series.

One of Ultech’s real-world implementations of CompactLogix is in engine-driven fire water pump systems, where reliability is paramount. In the event of a fire, these systems must start instantly and run continuously until manually stopped or until failure. There is no room for delay or premature shutdown.

The Fire Water Pump (FWP) system supplies high-pressure water to the platform’s firefighting network and is driven by an engine that starts automatically during a fire. Designed to run until failure or manual shutdown, it ensures continuous water flow during emergencies. An Allen-Bradley CompactLogix PAC controls the system in auto mode, responding to fire detection or sudden pressure drops. The PAC detects this drop and starts the pump to restore pressure.

The system follows a “run-until-fail” logic to prevent premature shutdown, maintaining operation even with fluctuating signals. The PAC also monitors engine health, detecting conditions like overspeed or faults. If a critical issue arises, the engine is flagged as “unhealthy” and blocked from restarting until cleared. Some setups include an MVR (Motorised Valve Relay) for added safety, acting as an isolation or interlock device based on control voltage or client-specific configurations.

Whether it's fire protection, critical process automation, or connected industrial systems, Ultech’s use of the CompactLogix PAC reflects our commitment to smart, safety-driven control in high-stakes environments. With its fast processing, modular design, and seamless integration into Rockwell Automation’s PlantPAx and FactoryTalk ecosystems, CompactLogix ensures dependable performance when safety cannot be compromised. From offshore fire water pump control to scalable safety architectures, the CompactLogix PAC is a cornerstone of Ultech’s mission to deliver intelligent, resilient, and future-ready automation. At OGA 2025, it represents how we engineer trust into every layer of our control solutions.

Another key highlight at Ultech Engineering’s OGA 2025 booth is our advanced control system integration using Mitsubishi Electric’s MELSEC iQ-R Series — a powerful, future-ready PLC platform built for demanding industrial applications. Known for its speed, safety, and intelligent data handling, the MELSEC iQ-R series is a cornerstone of Ultech’s work in energy systems and process automation.

Designed from the ground up to address modern industrial challenges, the MELSEC iQ-R platform focuses on seven critical areas: Productivity, Engineering, Maintenance, Quality, Connectivity, Security, and Compatibility. Its core features include:

The platform also supports backwards compatibility with MELSEC-Q Series I/O, enabling seamless migration with minimal hardware waste — a major advantage for cost-conscious upgrades.

With GX Works3 software, Ultech’s engineers develop and manage both general automation and safety control in a single, streamlined project file. This unified programming environment supports multilingual development, tag-based design, and preventive maintenance diagnostics, allowing fast commissioning and long-term reliability. The result: a compact, intelligent, and cybersecure solution for heat management in sensitive processes — all while reducing total cost of ownership.

In offshore gas engine systems, engine trips often occur due to high moisture content in the fuel gas supply. To address this, a superheater system is installed between the fuel gas supply and the compressor, right before the gas enters the engine. This superheater, essentially a heater vessel, is designed to strip out moisture from the gas stream, ensuring the fuel remains dry and suitable for combustion. At the heart of the system, the Mitsubishi Electric MELSEC iQ-R PLC precisely controls a thyristor, which energises the internal heater coils inside the vessel.

This targeted heating raises the gas temperature just enough to stay above its dew point, preventing condensation and significantly reducing moisture-related engine trips. The MELSEC iQ-R continuously monitors sensor inputs and modulates the thyristor in real time, providing a reliable, efficient, and automated moisture control solution in challenging offshore environments.

Whether it's intelligent heating, process control, or Industry 4.0 integration, Ultech’s deployment of the MELSEC iQ-R PLC series reflects our commitment to delivering future-ready automation in the most demanding industrial environments. By leveraging its high-speed architecture, built-in safety, and seamless digital connectivity, we ensure our systems not only perform reliably in critical applications — like offshore superheater control — but are also primed for scalable growth and digital transformation.

From heat-sensitive processes to smart factory integration, the MELSEC iQ-R stands as a key enabler in Ultech’s mission to engineer robust, intelligent, and sustainable control systems. At OGA 2025, this platform exemplifies how we bridge modern automation needs with long-term operational value.

Instrumentation plays a vital role in ensuring safety, reliability, and regulatory compliance, especially in hazardous and high-risk environments. At OGA 2025, Ultech Engineering, in collaboration with our partner SPT Maju Sdn Bhd, will showcase key products from Cabex and Weidmüller, trusted names in electrical components and industrial connectivity.

Ultech is proud to collaborate with SPT Maju Sdn Bhd, a Malaysian-based provider of instrumentation and electrical solutions with a strong presence across the oil and gas, marine, and industrial sectors. With years of field experience and a commitment to quality, SPT Maju has built a solid reputation for delivering safe, certified solutions to some of the most demanding projects in the region.

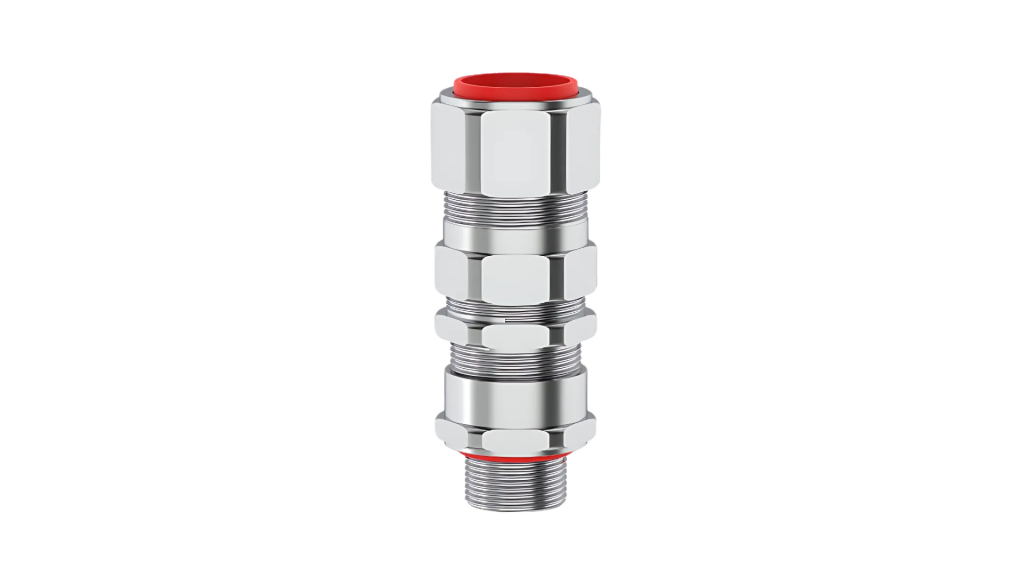

At OGA 2025, SPT Maju will showcase its range of Hazardous Area High Temperature Cable Glands, specifically the Ex E1FU-HT Cable Gland developed in partnership with Cabex Electrical Components, a leading electrical component brand. These cable glands are engineered specifically for Ex-rated zones where fire, explosion, or thermal hazards are present.

Key attributes of Cabex cable glands include:

These glands are critical components in ensuring the integrity of junction boxes and panel terminations, preventing moisture, gas, and dust ingress while maintaining fire-safe electrical connections. SPT Maju has partnered with Cabex to promote high-quality cable glands suitable for Ex d and Ex e applications, supporting compliance with ATEX, IECEx, and local safety standards in explosive zone control systems.

As an authorised partner of Weidmüller, Ultech Engineering brings a wide range of high-quality German-engineered components to the Malaysian industrial market. Founded in 1850 and headquartered in Detmold, Germany, Weidmüller is globally recognised for its innovation in electrical connectivity, automation, and industrial electronics — serving sectors from process automation to power generation and smart manufacturing.

At OGA 2025, Ultech Engineering is proud to spotlight a curated lineup of Weidmüller solutions purpose-built for harsh and hazardous environments. This showcase features:

Weidmüller’s explosion-proof enclosures on display include

At OGA 2025, Weidmüller shifts the spotlight from Ex-rated components to empowering technicians with high-performance tooling. The 2025 Tools Bundle Set Promo showcases three precision-engineered crimping tool sets—CTI 6 SD, PZ 6 ROTO L SD, and STRIPAX SD—each designed for professional-grade efficiency and ergonomic comfort.

Every bundle comes complete with a voltage tester, slotted screwdriver, and Phillips crosshead screwdriver, offering a versatile toolkit for panel assembly, field termination, and maintenance work. Visitors to the Ultech Engineering booth can get a hands-on look at how Weidmüller tools streamline installation and ensure consistent, reliable results in demanding industrial environments.

At OGA 2025, Ultech Engineering, in collaboration with Weidmüller and our partner SPT Maju Sdn Bhd, in partnership with Cabex, come together to highlight robust, Ex-certified solutions tailored for hazardous and high-risk environments. From Weidmüller’s 2025 Tools Bundle Set Promo to explosion-proof enclosures and local control stations, these components serve as the foundation for safe, reliable, and standards-compliant panel systems.

Ultech’s integration expertise with Weidmüller’s industrial connectivity solutions, combined with SPT Maju’s offering of Cabex hazardous area cable glands, ensures that our customers benefit from trusted technologies designed to perform under pressure. Together, we showcase how safety, modularity, and engineering excellence come together in real-world solutions built for the energy sector.

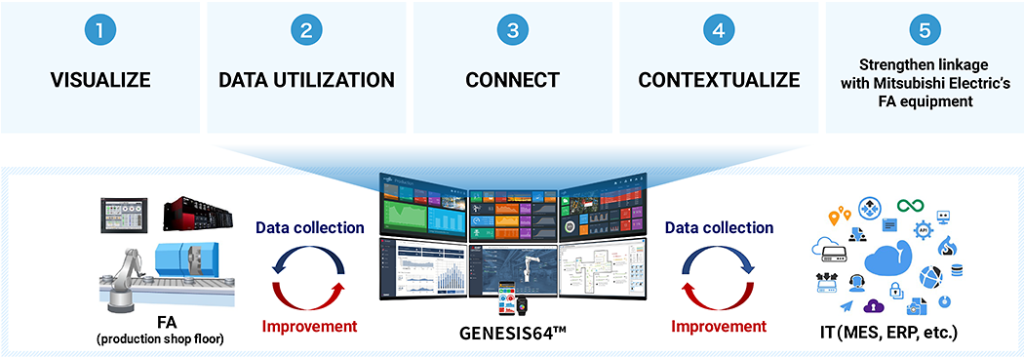

In today’s increasingly connected industrial landscape, visibility and integration are no longer optional—they’re fundamental. Mitsubishi Electric’s GENESIS64™ is a 64-bit, web-based SCADA (Supervisory Control and Data Acquisition) platform that enables secure, real-time monitoring, control, and analysis of industrial systems.

GENESIS64 enables real-time visualisation of all connected equipment across any device—control room screens, laptops, tablets, smartphones, or even wearables. At OGA 2025, one SCADA screen will be installed at the booth for live monitoring, while a second will simulate remote access, demonstrating how operators can stay connected even when off-site.

With built-in tools for Overall Equipment Effectiveness (OEE), Statistical Process Control (SPC), energy analytics, and fault detection, GENESIS64 transforms operational data into actionable insights. It helps visitors see how production metrics and energy usage can be visualised clearly, even across different brands of equipment.

GENESIS64’s open connectivity—supporting OPC UA, Modbus, SNMP, BACnet, and MQTT—enables integration with diverse hardware platforms. At the booth, this allows it to pull real-time data from:

This demonstrates the SCADA’s power to bring multiple technologies into one seamless operational view.

Rather than displaying isolated data points, GENESIS64 organises data by physical assets—such as switchboards, MCCs, gensets, and PLC racks—making it easier to navigate and understand operational relationships. This asset-based visualisation enhances clarity and speeds up diagnostics during fault events.

GENESIS64 is deeply compatible with Mitsubishi Electric hardware. At OGA 2025, it will serve as the visualisation platform for the iQ-R PLC, allowing users to track system statuses, alarms, and process values with minimal configuration effort, showcasing the seamless synergy between SCADA and FA products.

At Ultech’s OGA 2025 booth, GENESIS64™ SCADA acts as the central monitoring layer, linking power management across the AGC150 genset controllers, as well as the operations of the superheater and firewater pump systems. By showcasing both local and remote interfaces, Ultech demonstrates how a modern SCADA system empowers operators to monitor, analyse, and respond in real time. Integrated with DEIF, Allen-Bradley, and Mitsubishi Electric platforms, GENESIS64 doesn’t just display data—it unifies it, offering a complete, real-time view of industrial processes from one centralised platform, anywhere, anytime.

As Ultech Engineering returns to OGA 2025, our booth isn’t just a product showcase — it’s a live demonstration of how smart automation, reliable power control, and industrial connectivity come together to drive real-world performance. From industrial-grade PLCs and intelligent genset controllers to explosion-proof instrumentation and cutting-edge SCADA integration, every solution on display reflects our commitment to safer, smarter, and more resilient industrial operations.

Whether you're an engineer seeking robust systems, a decision-maker exploring digital transformation, or a partner looking for collaborative opportunities, Ultech’s presence at OGA 2025 offers valuable insights into the future of integrated automation. By integrating the capabilities of DEIF, Rockwell Automation, and Mitsubishi Electric through platforms like GENESIS64™ and showcasing Weidmüller’s and Cabex's advanced components for hazardous environments, we’re enabling industries to move forward efficiently, securely, and with confidence.

We invite you to visit our booth to explore our latest innovations and solutions in the oil and gas sector. Join us to see firsthand how we continue to drive excellence in engineering and technology. Pre-register your attendance here!: OGA Website