FactoryTalk AssetCentre cannot be purchased as a standalone; rather, it is utilized in conjunction with Rockwell Automation SCADA information. Serving as a centralised tool, which efficiently secures, manages, versions, tracks, and reports automation-related asset information throughout the entire facility. Additionally, within the realm of Rockwell Software, the FactoryTalk Security Platform is a comprehensive suite of services encompassing alarms and Events, Activation, Security, Audit, Directory, and Live Data. It is crucial to note that FactoryTalk is not available for standalone purchase; rather, it is an integrated component within the broader Rockwell Automation ecosystem.

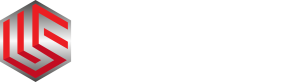

In the fast-paced realm of industrial automation, the release of FactoryTalk AssetCentre software version 13.00 marks a significant milestone. This version introduces a myriad of features, but a notable highlight is the Asset Lifecycle Dashboard. This dashboard acts as a centralized hub, aggregating multiple inventory files based on user-defined asset tree selections. The resulting visual representation provides a comprehensive and summarized overview of device information, categorized for efficient management.

The Asset Lifecycle Dashboard not only aggregates information but also allows for detailed insights into individual devices. Through a property panel slide-out, users can access intricate details about each device. Additionally, the ability to export a filtered view facilitates streamlined management, enabling users to capture devices that demand attention. This feature responds to the increasing need for proactive device lifecycle management in light of evolving laws, standards, and executive orders.

FactoryTalk Security Platform software leaps forward in user authentication by integrating with Microsoft Azure. This integration brings forth a range of cloud-based MFA authentication options, ensuring a robust security framework. Users can leverage Microsoft Authenticator, opt for one-time phone codes delivered via SMS, receive authentication through voice calls, or utilize security tokens. Notably, the software extends support to both Azure AD (AAD) and Azure AD Directory Services (AADDS) groups, introducing a new Azure-linked group type.

Recognizing the significance of on-premises MFA, FactoryTalk Security Platform seamlessly integrates with OpenID Connect identity providers. This integration empowers users to implement on-premises MFA using diverse factors such as one-time phone codes via SMS, biometrics, RFID cards, and NYMI brands. Notably, this solution operates seamlessly through existing FactoryTalk Security Windows-linked groups. This flexibility allows customers to integrate third-party identity management solutions for robust on-premises authentication.

As industries navigate through an era of constantly evolving regulations, the Asset Lifecycle Dashboard proves to be a valuable tool for proactively managing devices. Beyond aggregation and detailed insights, this feature actively supports compliance efforts. By summarizing inventory and presenting it in a user-friendly dashboard, the system allows for quick identification of devices that may require attention.

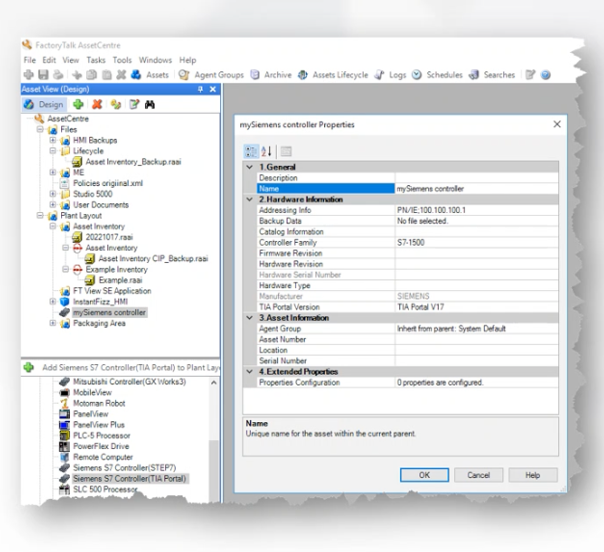

In response to the critical need for efficient disaster recovery processes, FactoryTalk AssetCentre introduces intrinsic third-party capabilities. This includes licensed support for disaster recovery in Siemens TIA Portal and Mitsubishi systems. The built-in support significantly reduces the need for developing and maintaining automation scripts for support vendors, streamlining the disaster recovery workflow.

Siemens, a prominent player in industrial automation, has a range of PLC (Programmable Logic Controller) families, including the S7-1200/1500, ET 200 family, S7-300, and S7-400. These PLCs serve various purposes, from compact controllers to high-performance automation systems.

In FactoryTalk AssetCentre, third-party disaster recovery capabilities have been extended to Siemens systems using the TIA (Totally Integrated Automation) Portal. This includes support for various versions of the TIA Portal, such as 18, 17, 16, and 15.1, with compatibility for PN/IE (Profinet/Industrial Ethernet), PROFIBUS, and MPI (Multi-Point Interface) connections.

However, it's important to note that FactoryTalk AssetCentre provides disaster recovery support for Siemens systems but does not offer a built-in backup and compare functionality for these Siemens PLC families.

Mitsubishi Electric offers a diverse range of programmable controllers, and FactoryTalk AssetCentre provides disaster recovery support for several series within the Mitsubishi lineup.

The supported families include the iQ-R Series, iQ-F (FX5) Series, Q Series (QCPU) Controllers, L Series Controllers, and F Series Controllers. These controllers cover a wide spectrum of applications, from high-performance industrial automation to compact and modular control systems.

For Mitsubishi Electric controllers, FactoryTalk AssetCentre supports disaster recovery using the GX Works engineering software. This includes versions GX Works3 and GX Works2. However, similar to Siemens, there is no built-in backup and compare functionality for Mitsubishi Electric PLC families within FactoryTalk AssetCentre.

Overall, FactoryTalk AssetCentre's third-party disaster recovery capabilities extend to Siemens and Mitsubishi Electric PLC families, offering support for key series and versions commonly used in industrial automation. While providing essential disaster recovery features, users should be aware that the platform does not include built-in backup and compare functionality for these specific Siemens and Mitsubishi Electric controllers.

In conclusion, the enhanced compatibility of Rockwell Automation's FactoryTalk AssetCentre and Security Platform in 2024 brings significant advancements to the industrial automation landscape. The introduction of FactoryTalk AssetCentre software version 13.00, featuring the Asset Lifecycle Dashboard, provides a centralized hub for efficient management of automation-related assets. This dashboard not only aggregates information but also offers detailed insights into individual devices, supporting proactive device lifecycle management.

The FactoryTalk Security Platform software leaps forward in user authentication with multi-factor authentication (MFA) alternatives. The integration with Microsoft Azure brings cloud-based MFA options, while on-premises authentication is seamlessly achieved through OpenID Connect identity providers. This flexibility allows users to implement MFA using diverse factors, including one-time phone codes, biometrics, RFID cards, and more.

Moreover, the AssetCentre introduces intrinsic third-party disaster recovery capabilities, addressing the critical need for efficient disaster recovery processes. The support extends to Siemens TIA Portal and Mitsubishi Electric systems, covering various PLC families within these manufacturers. While providing disaster recovery support, it's important to note that FactoryTalk AssetCentre does not offer built-in backup and compare functionality for Siemens and Mitsubishi Electric PLC families.

In essence, these advancements signify Rockwell Automation's commitment to addressing industry needs, enhancing security, and streamlining asset management and disaster recovery processes in the dynamic field of industrial automation.