In industries where reliability is non-negotiable, the ability to maintain continuous operations during unexpected disruptions defines the strength of a system. For PETRONAS Gas Berhad (PGB), one of Malaysia’s leading energy infrastructure companies, this principle is especially crucial at its Segamat Compressor Station (SCS). Compressor stations are vital links in the nation’s gas transmission network, ensuring a stable and safe supply of natural gas across regions. Any disruption in power supply, even for a short period, has the potential to impact operations, safety, and downstream customers.

To safeguard against such risks, auxiliary systems are put in place to provide immediate and reliable backup power when the main utility source is interrupted. This is where the Auxiliary Power Unit (APU) Gas Engine Generator plays a defining role.

An Auxiliary Power Unit (APU) Gas Engine Generator is essentially a self-contained backup power solution. As its name suggests, it runs on gas — often natural gas, aligning with the facility’s existing fuel infrastructure — and generates electricity independently of the main grid.

At its core, the APU functions as a lifeline system. When the primary power source, such as the supply from Tenaga Nasional Berhad (TNB), becomes unavailable due to an outage, the APU activates automatically. Within seconds, it takes over the load to ensure that essential equipment and operations continue running seamlessly.

The APU is complemented by a Generator Control Panel (GCP), which acts as the “brain” of the setup. The GCP continuously monitors the incoming power supply, detects failures, and initiates the startup of the generator. It also manages the transition of load between the main power and the backup generator, protects the system against faults, and provides real-time monitoring data such as voltage, current, and frequency.

Together, these systems deliver a fail-safe mechanism that guarantees uninterrupted power — a critical requirement for compressor stations like PGB Segamat.

The Segamat Compressor Station plays a critical role in PETRONAS Gas Berhad’s transmission network. Its operations rely on electricity to drive key processes, equipment, and safety systems. With the increasing complexity and demand of modern energy infrastructure, relying on older or outdated generator control panels becomes a risk factor.

Prior to this project, the existing Generator Control Panel (GCP) at Segamat was aged and based on older technology. While it had served its purpose, its limitations in reliability, monitoring, and safety protections made it necessary for an upgrade. For PGB, ensuring that the auxiliary system could deliver uncompromised performance during TNB power outages was not optional — it was a strategic imperative.

This is where Ultech Engineering stepped in to deliver the 965kW Auxiliary Power Unit Gas Engine Generator Control Panel Upgrade, commissioned and completed in 2024.

Ultech Engineering was entrusted with the responsibility of providing a comprehensive solution — from the supply and installation of advanced equipment to testing, commissioning, and operator training. The scope of work centered around modernizing the APU system with state-of-the-art technologies that would not only improve reliability but also provide enhanced safety redundancies, better monitoring capabilities, and seamless integration with PGB’s existing Distributed Control System (DCS).

By leveraging proven technologies such as the DEIF AGC 150 controller, Allen-Bradley PLC, and DEIF MVR G215 protection relay, Ultech ensured that the new system could meet PETRONAS’ high standards of operational excellence.

This article provides a full project recap of the 965kW Auxiliary Power Unit Gas Engine Generator Control Panel Upgrade at PGB Segamat. It outlines the objectives, technologies, challenges, and solutions implemented by Ultech Engineering, while also sharing the feedback and benefits experienced by the client.

The story of this project is not just about upgrading equipment — it is about building resilience into critical infrastructure, enabling smoother operations, and strengthening trust in Malaysia’s energy network.

The Segamat Compressor Station (SCS), part of PETRONAS Gas Berhad’s (PGB) extensive transmission network, is a high-stakes facility where uptime is paramount. Compressor stations like SCS form the backbone of Malaysia’s natural gas supply chain. They ensure that gas pressure levels are maintained throughout pipelines, allowing stable and secure distribution to industries, businesses, and households.

In such an environment, even a short disruption in power can create operational inefficiencies, safety risks, and costly downtime. Given this critical backdrop, the primary objective of the project was straightforward yet essential:

To upgrade the Auxiliary Power Unit (APU) Gas Engine Generator Control Panel to the latest technology, thereby ensuring a dependable auxiliary power supply during Tenaga Nasional Berhad (TNB) outages.

This upgrade was not just a technical requirement but also a strategic investment by PGB to future-proof the Segamat facility against power interruptions and system vulnerabilities.

Ultech Engineering and PETRONAS Gas Berhad aligned on several key objectives when initiating the project:

Upgrade outdated GCP equipment to a modern system capable of delivering consistent and uninterrupted performance during power outages.

Integrate advanced fault detection, safety interlocks, and a dedicated protection relay to safeguard both equipment and personnel.

Ensure smooth and immediate transition of load from TNB’s power supply to the auxiliary generator, with minimal to zero downtime.

Provide operators with greater visibility into system status through enhanced monitoring tools and seamless communication with the station’s Distributed Control System (DCS).

Reduce manual intervention during outages by automating responses, and extend system lifespan through optimized equipment performance.

Adopt proven, scalable technologies that could adapt to future operational demands and align with PETRONAS’ long-term sustainability and efficiency goals.

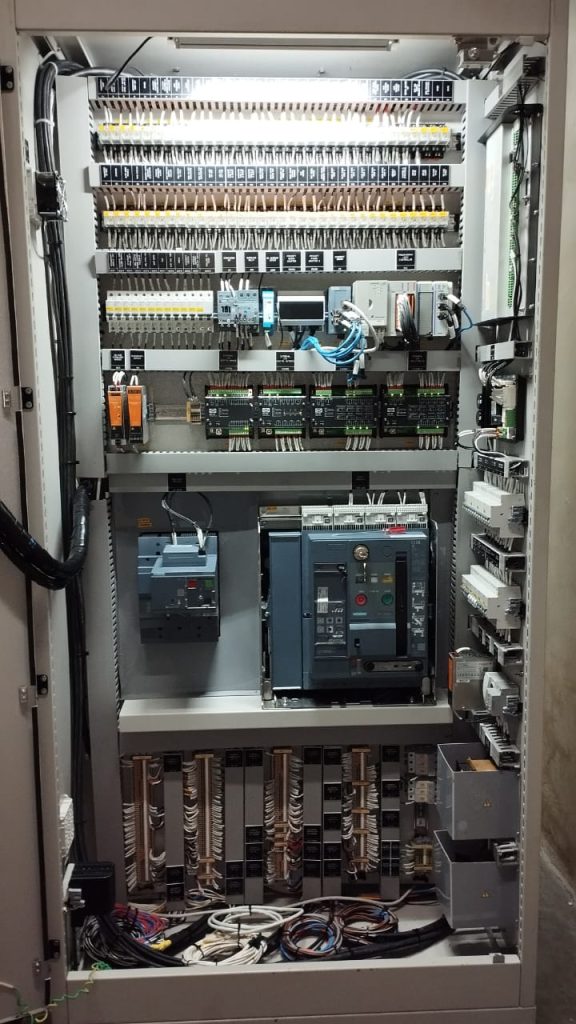

Ultech Engineering’s project scope went beyond a simple panel replacement. It encompassed the full cycle of design, supply, installation, testing, commissioning, and training to ensure a turnkey solution for PGB Segamat.

The major deliverables included:

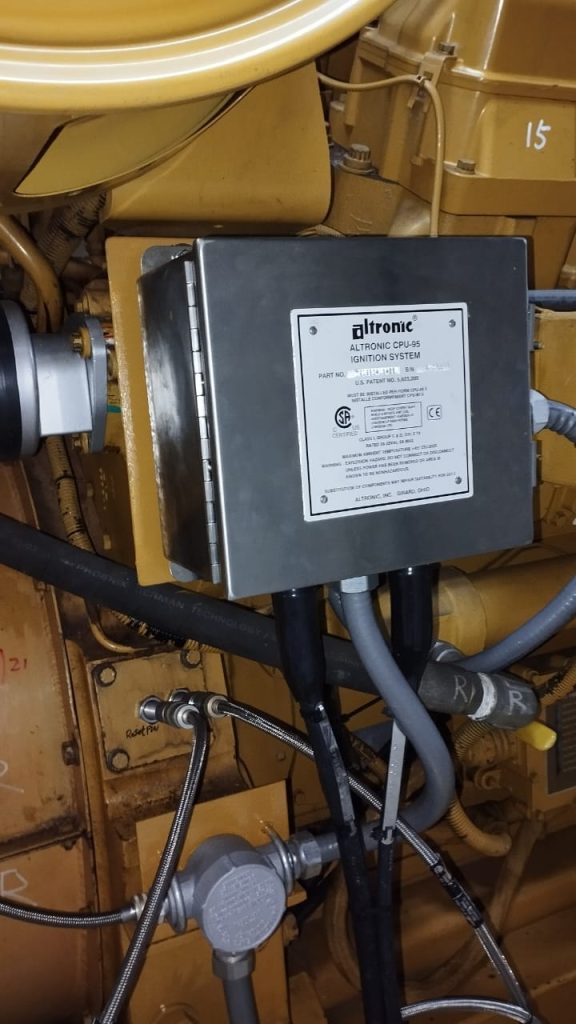

Incorporating the DEIF AGC 150 controller as the central brain of the generator system.

To monitor additional sensors and ensure communication with the DCS via Modbus protocol.

Providing redundancy and an additional layer of safety for fault detection and prevention.

Addressing challenges in cable entry and ensuring proper sealing with gaskets to protect against potential wear and damage.

Comprehensive FAT (Factory Acceptance Testing) and SAT (Site Acceptance Testing) to validate system performance, safety, and compliance with client requirements.

Delivery of detailed training sessions and manuals to empower PGB operators with the knowledge required to operate and maintain the system.

Establishing a framework for remote assistance and continuous support, ensuring long-term system reliability.

While the immediate goal was to replace outdated equipment, the scope of this project reflects a much larger impact: building resilience into Malaysia’s critical gas transmission infrastructure. With the upgraded APU system, PGB Segamat gains:

By clearly defining and delivering on these objectives, Ultech Engineering ensured that the project not only met its technical goals but also created meaningful long-term value for the client.

At the heart of this project is the need to balance cutting-edge control technology with the operational realities of a high-demand industrial site like the Segamat Compressor Station. The outdated control panel no longer met PETRONAS Gas Berhad’s standards for safety, efficiency, or future scalability.

Ultech Engineering’s approach was to carefully select proven, industry-leading solutions that not only met the present needs but also future-proofed the facility. Three key technologies became the backbone of this upgrade:

Each of these components was chosen deliberately for its unique strengths, integration potential, and proven reliability in mission-critical environments.

The DEIF AGC 150 is the central control unit for the auxiliary gas engine generator. It functions as the “brain” of the system, responsible for decision-making and automation whenever the facility experiences a power outage.

Detects the loss of power from Tenaga Nasional Berhad (TNB) and immediately initiates the generator start-up sequence. The controller then transfers the electrical load seamlessly from the utility to the generator without manual intervention.

When the TNB supply is restored, the AGC 150 switches the load back to the main power supply smoothly and shuts down the generator. This eliminates unnecessary runtime and prolongs equipment life.

Provides real-time data on voltage, current, frequency, and power output. Operators can quickly detect abnormalities and ensure the generator is running at optimal efficiency.

Supports different modes of operation, including island mode, mains parallel mode, and standby mode. This adaptability allows PGB to customize system behavior depending on operational needs.

The AGC 150 was selected for its proven track record in power-critical industries, ease of integration with other equipment, and strong manufacturer support. Its built-in safety and control features reduce reliance on multiple devices, making the system more streamlined and less prone to failure.

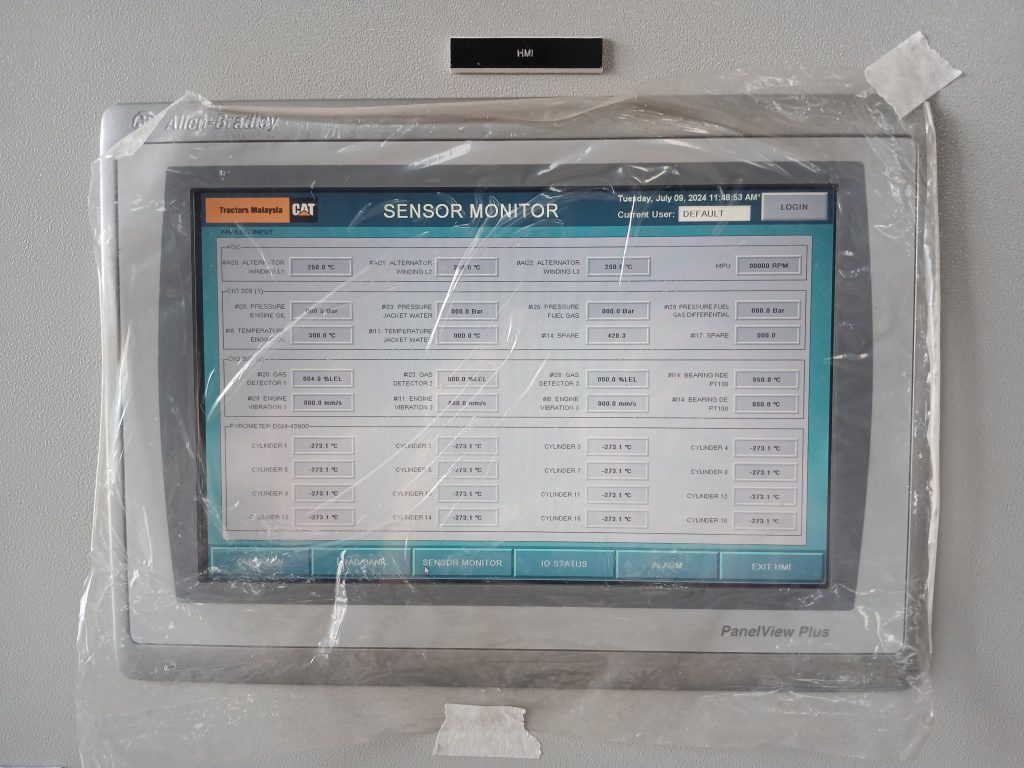

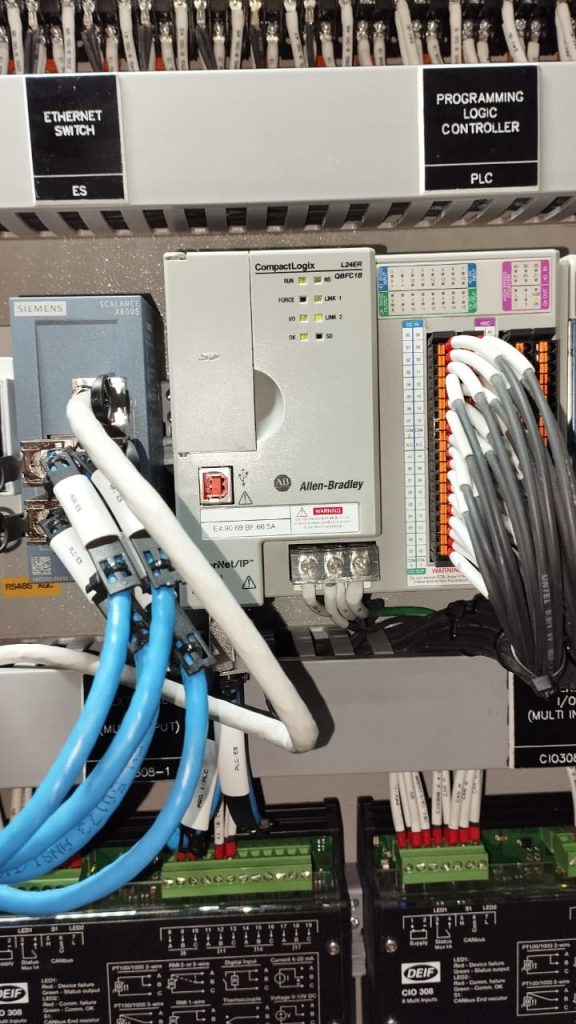

While the DEIF AGC 150 handles core generator functions, additional monitoring and communication requirements demanded another layer of intelligence. This is where the Allen-Bradley Programmable Logic Controller (PLC) was brought into the design.

The PLC collects data from additional sensors installed around the genset and compressor station. These include temperature sensors, pressure transmitters, and vibration monitors — all critical for predictive maintenance.

The Allen-Bradley PLC uses Modbus protocol to exchange data with the central DCS room at Segamat. This ensures operators have a single, centralized view of all critical systems, improving decision-making and reducing the risk of oversight.

Allen-Bradley PLCs are known for their adaptability. The engineering team can program custom logic tailored to the client’s operational requirements, making the system future-ready.

The Allen-Bradley PLC was chosen for its compatibility, reliability, and strong industrial footprint in Malaysia’s oil and gas sector. PETRONAS facilities already deploy Allen-Bradley systems in many locations, ensuring ease of maintenance, local support, and operator familiarity.

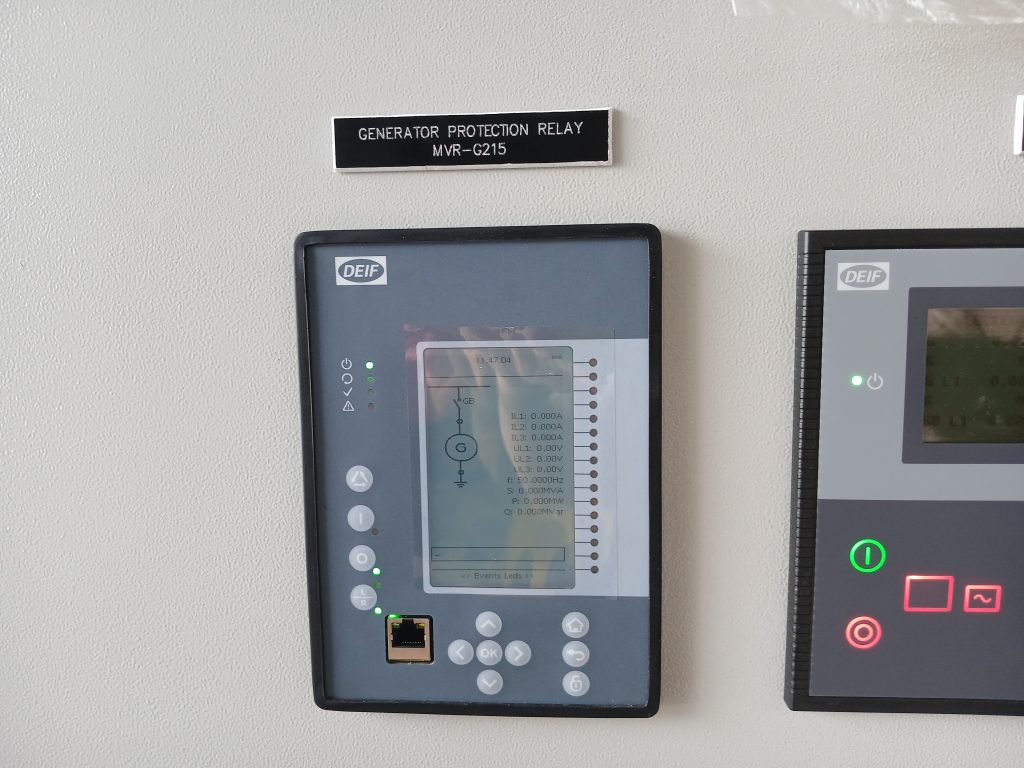

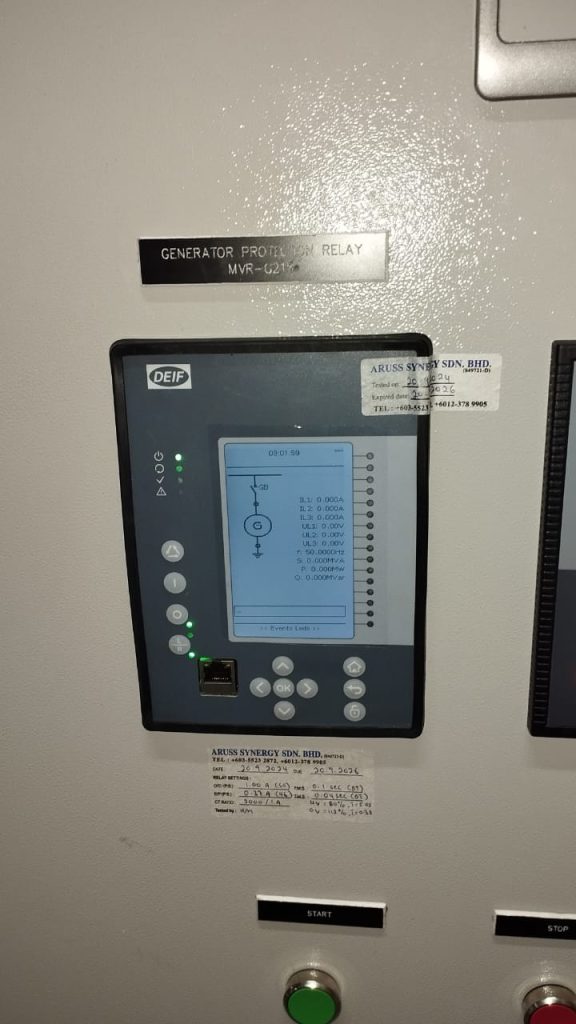

No matter how advanced a control system may be, safety redundancy is non-negotiable in mission-critical facilities. This is why a dedicated protection relay, the DEIF MVR G215, was integrated alongside the AGC 150.

Operates as a standalone safety device, separate from the main controller. Even if the AGC 150 fails, the G215 continues to safeguard the generator.

Continuously monitors for over-voltage, under-voltage, over-frequency, under-frequency, over-current, and other electrical faults.

In case of a detected fault, the relay sends a trip signal to immediately disconnect the generator from the load, protecting both the genset and the connected equipment.

Records fault history, enabling operators to troubleshoot issues quickly and accurately.

The DEIF MVR G215 provides critical redundancy. In high-value facilities like PGB Segamat, relying on a single controller for both control and protection would be risky. By separating these functions, the system ensures maximum resilience and compliance with international safety standards.

What makes this system powerful is not just the individual components but the way they work together:

This layered approach is a reflection of Ultech Engineering’s design philosophy: never compromise on safety, reliability, or client confidence.

By selecting technologies with strong reputations, global support, and compatibility with existing infrastructure, Ultech Engineering ensured that this upgrade is not just a short-term solution but a future-ready investment. PETRONAS Gas Berhad can now rely on a system that will support its operations for years to come, while being flexible enough to adapt to future upgrades or expansions.

Executing engineering upgrades in operational energy facilities is never a straightforward task. At the Segamat Compressor Station (SCS), where every system plays a vital role in ensuring uninterrupted gas flow, the stakes were even higher. For Ultech Engineering, the challenge was not only to install and commission the upgraded control panel but to do so in a way that minimized disruption, addressed on-site realities, and aligned with PETRONAS Gas Berhad’s uncompromising standards.

The project unfolded with its own set of obstacles — technical, logistical, and procedural. Yet, each challenge was approached with a mindset of solutions, not setbacks. Below are some of the key hurdles and how they were resolved.

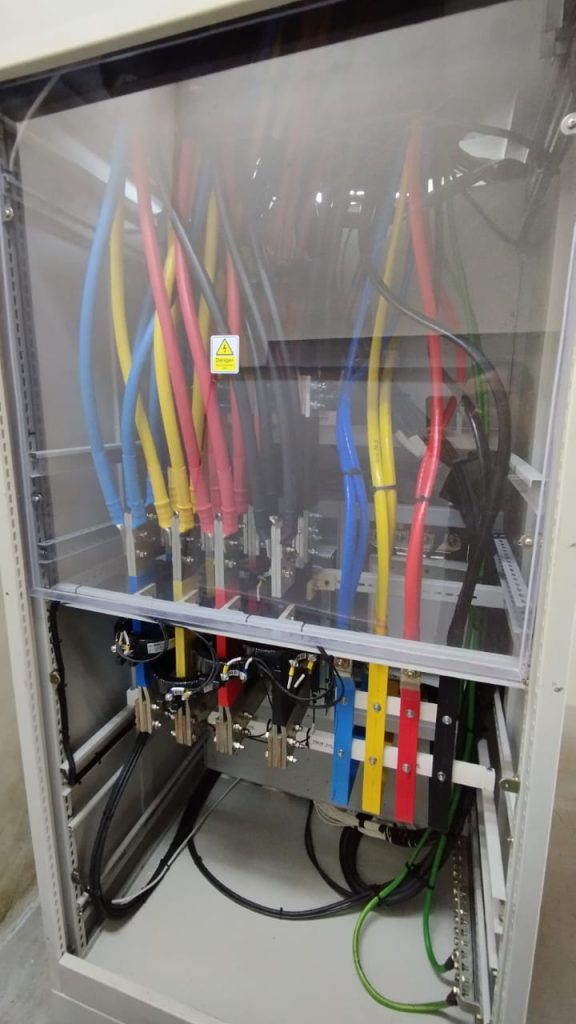

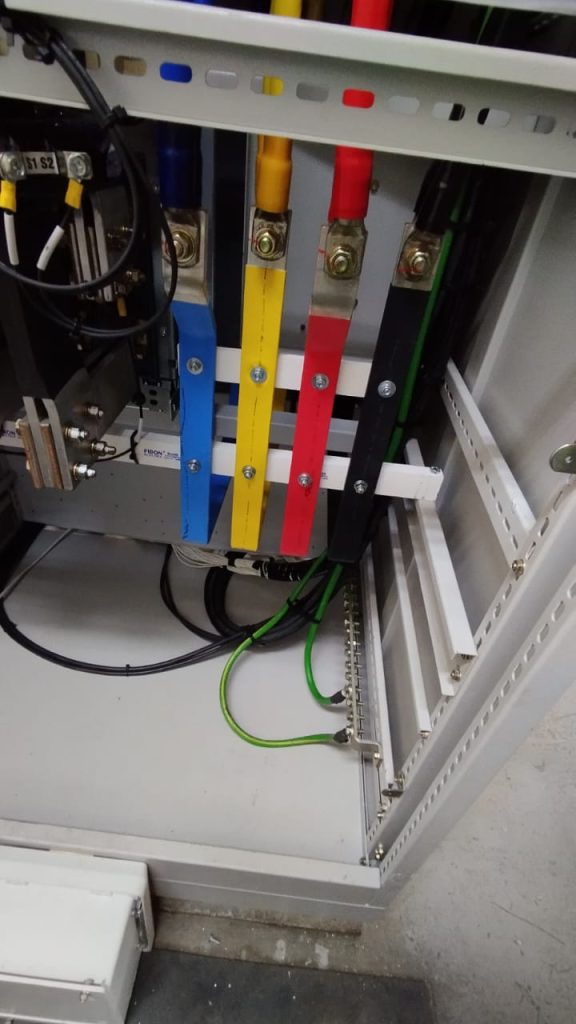

One of the earliest challenges arose during the installation stage. The existing panel structure did not align with the cable specifications for the new system. This meant that the cable entrance had to be modified to prevent strain and potential damage to the cables during operation.

The engineering team worked closely with suppliers to design a modification that would allow cables to be routed safely without compromising structural integrity. A gasket was added to ensure proper sealing, preventing wear and providing additional protection against environmental exposure. This adjustment not only solved the immediate issue but also extended the durability of the installation.

Both the Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT) phases provided important client feedback. At FAT, the client emphasized the importance of validating every sensor setpoint to guarantee safe genset performance. At SAT, two major issues surfaced: the HMI (Human-Machine Interface) design required modification, and the back door panel needed redesigning to better accommodate the load bank cable entry.

Ultech Engineering approached this feedback as opportunities for refinement rather than setbacks. The HMI design was modified to provide clearer navigation and usability for operators. Similarly, the panel’s back door was reworked to allow easier cable access and reduce setup time during load bank operations. These adjustments not only satisfied the client but also made the system more operator-friendly in the long run.

Integrating modern solutions like the DEIF AGC 150, Allen-Bradley PLC, and DEIF MVR G215 into an existing facility meant working around legacy infrastructure that was not originally designed for these components.

The team carried out thorough inspections and collaborated closely with PETRONAS’ on-site engineers to ensure compatibility. Careful calibration, programming, and testing bridged the gap between the new technologies and the older systems. The result was seamless integration that strengthened the overall reliability of the Segamat Compressor Station.

As with most critical energy projects, timelines were tight. Delays could affect operational readiness and impact the wider transmission network.

Ultech Engineering implemented structured project management practices, including daily coordination meetings, progress reporting, and close supplier collaboration. These ensured that challenges were identified early and resolved quickly without causing major delays. The project was ultimately completed within the agreed timeframe, preserving client confidence.

While the upgraded system brought advanced features, it also introduced a learning curve for operators accustomed to the old panel.

Ultech Engineering placed strong emphasis on training. Formal sessions, practical demonstrations, and detailed operation manuals were delivered to ensure that the client’s team could confidently operate and maintain the system. By focusing on people as much as on technology, the project handover was smooth and empowering for the client.

Every project carries with it a unique set of challenges, and the Segamat upgrade was no exception. Yet, through teamwork, technical expertise, and a commitment to client success, Ultech Engineering not only overcame these challenges but also delivered a system that stands as a benchmark of reliability and safety.

For the engineers involved, the successful completion of this project went beyond technical achievement. It reinforced a strong sense of purpose: contributing to the resilience of Malaysia’s energy infrastructure and supporting PETRONAS Gas Berhad’s mission to deliver safe, reliable, and efficient gas transmission.

The successful completion of the 965kW Auxiliary Power Unit Gas Engine Generator project at PGB Segamat is more than just the end of an engineering contract—it represents Ultech Engineering’s broader philosophy of creating lasting impact through reliable solutions.

Every installation, every test, and every handover was guided by our dedication to precision and accountability. But the journey does not stop here. For us, project delivery is not just about checking boxes—it is about ensuring our partners can operate with confidence and efficiency long after the systems are commissioned.

That is why Ultech Engineering emphasizes continuous support. From technical guidance to performance optimization, we remain present for our clients, ensuring that the systems installed continue to perform at their peak capacity. This approach is not just about service—it is about partnership, about walking together with our clients as they grow, expand, and face the challenges of tomorrow.

In the end, the PGB Segamat project embodies what Ultech Engineering stands for: reliability, resilience, and responsibility. It reminds us that every challenge overcome leads to a greater sense of achievement, and every project completed brings us closer to our purpose—delivering engineering excellence that fuels progress.