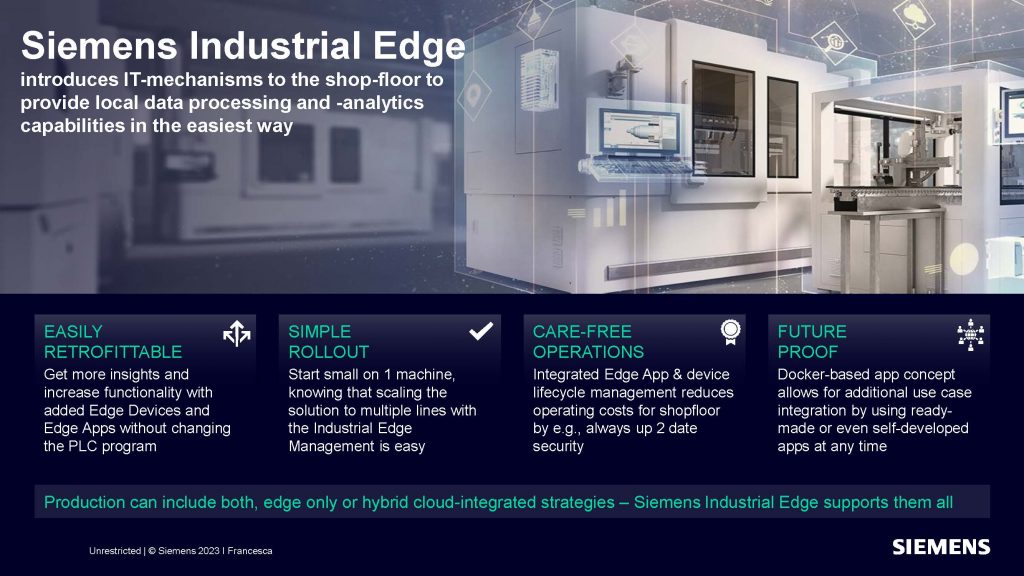

Siemens Industrial Edge is more than just a technology; it's a comprehensive system of hardware and software aimed at providing a scalable, reliable, and user-friendly solution for industrial settings. The primary objective is to empower management-level personnel with the tools to analyze and optimize the performance, efficiency, spending, and operating costs of factories and plants.

It's essential to highlight that Siemens IE stands apart from Supervisory Control and Data Acquisition (SCADA) systems typically employed by plant operators. While SCADA systems focus on real-time monitoring and control of industrial processes, Siemens IE takes a broader approach, catering to the managerial level for in-depth analysis and decision-making.

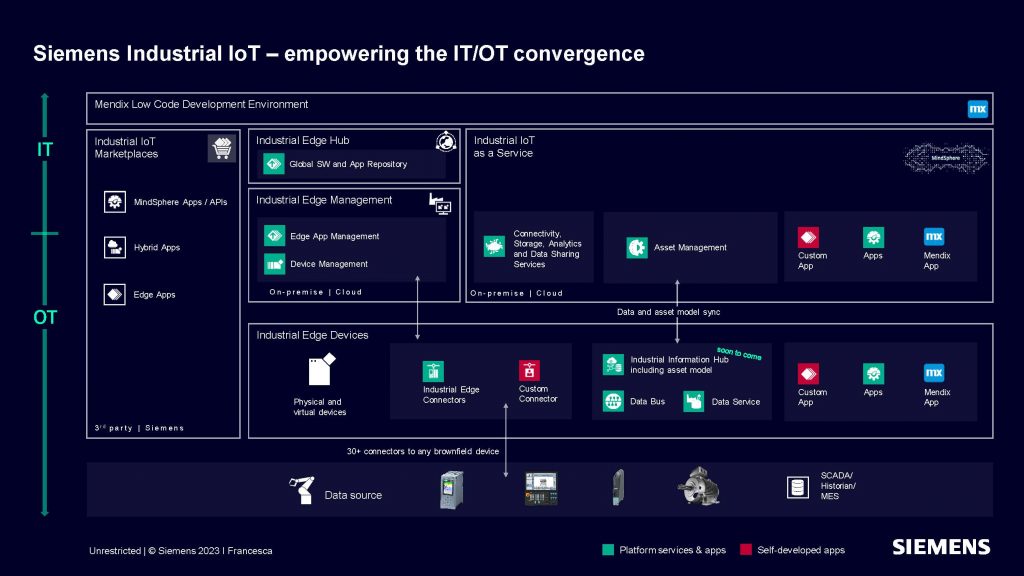

In the ever-evolving landscape of industrial technology, the integration of cutting-edge solutions becomes paramount to enhancing efficiency, performance, and overall productivity. One such innovation making waves in the industrial sector is Siemens Industrial Edge (IE), a sophisticated system designed to seamlessly integrate information technology (IT) into the shop floor. Before delving into Siemens IE and its marketplace, let's grasp the broader concept of edge computing.

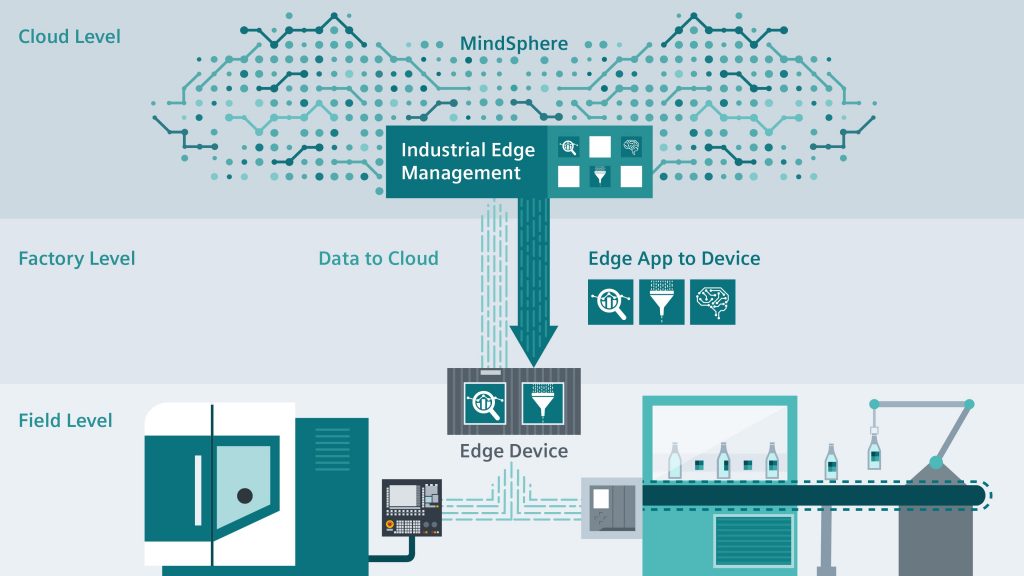

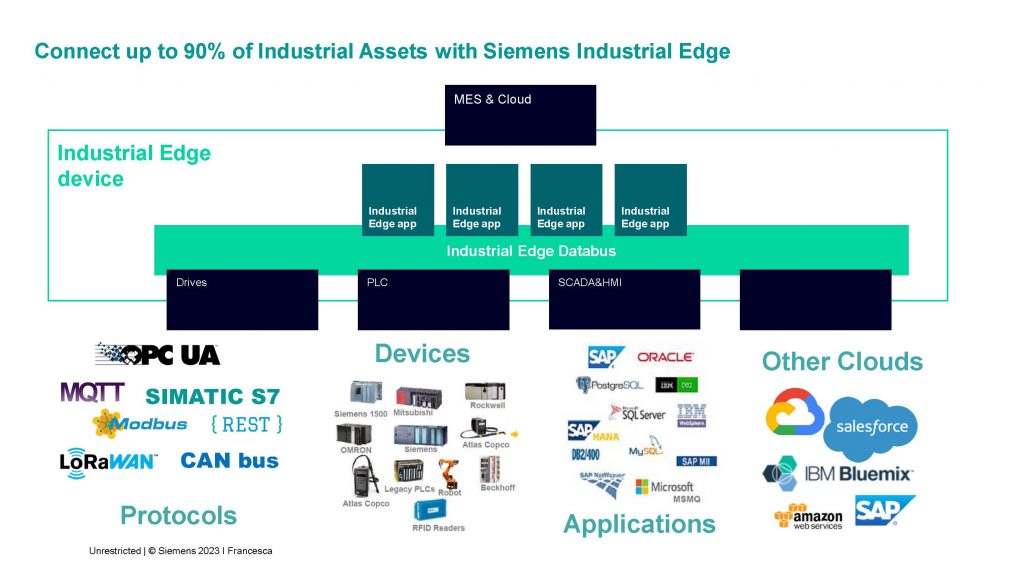

Edge computing involves processing data closer to the source of generation, reducing latency and improving real-time decision-making. This is especially crucial in industrial settings where rapid responses and low-latency data processing are imperative. Unlike traditional cloud computing, which relies on centralized data processing, edge computing distributes computation and data storage closer to the devices and sensors at the edge of the network.

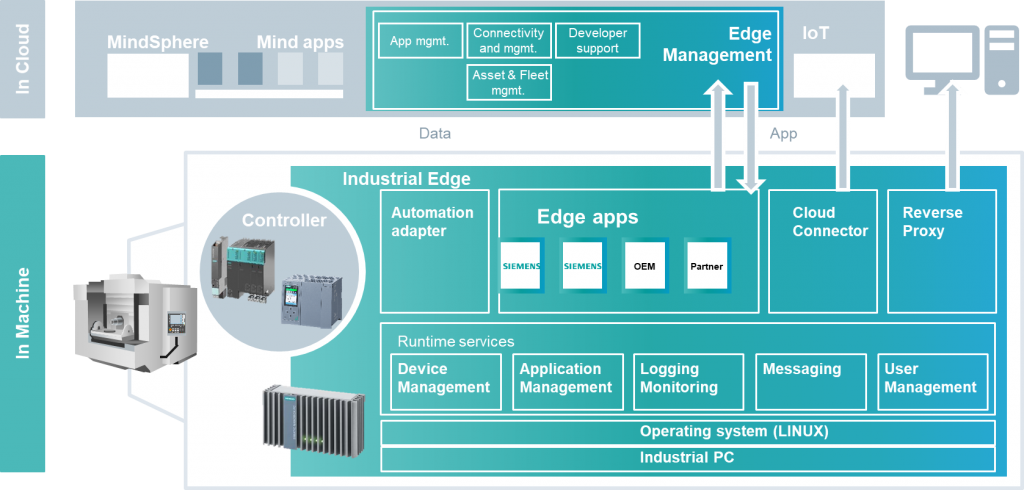

Siemens IE is structured around three integral components:

One standout feature of Siemens IE is the IE Management (IEM) component. It allows customers to procure or develop applications that align with their unique requirements. These applications can then be seamlessly downloaded to all IE Devices within the factory, streamlining processes such as app deployment and firmware updates.

Moreover, the collected performance data from various factory processes is transmitted to IEM. This centralized data hub empowers managers with a comprehensive view of plant performance, efficiency metrics, spending patterns, operating costs, and essential key performance indicators (KPIs).

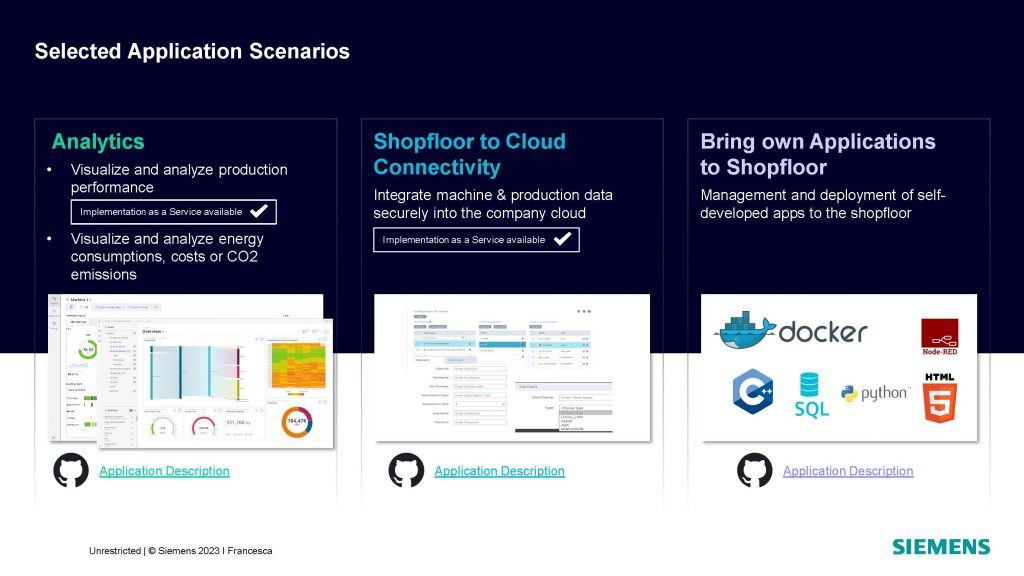

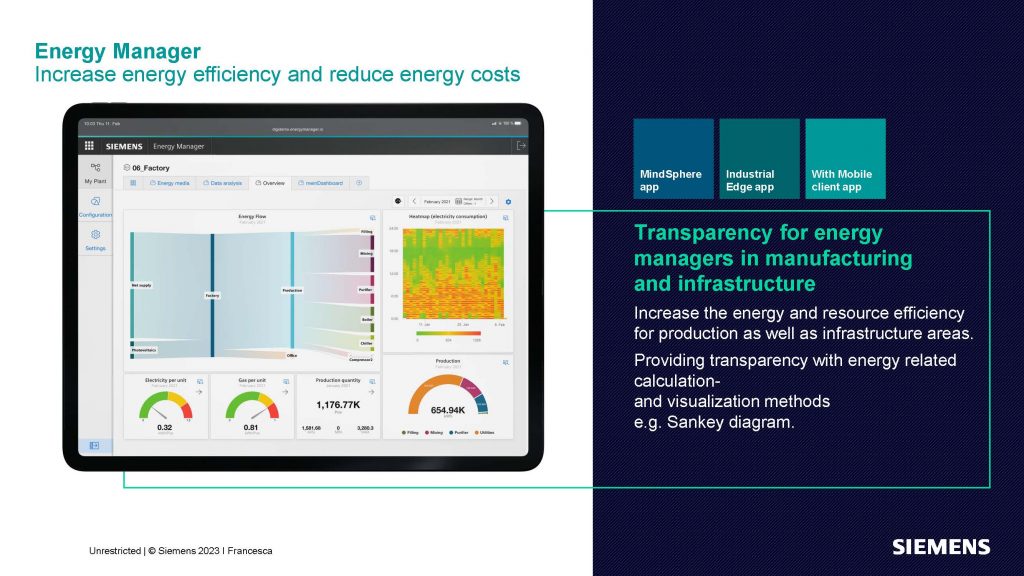

Siemens IE goes beyond mere data collection. It provides users with intuitive dashboards featuring multiple templates. These templates allow for easy configuration, enabling users to tailor the dashboards according to the specific data they wish to monitor.

Furthermore, Siemens IE facilitates customization by allowing users to integrate calculation formulas seamlessly. This includes key performance indicators (KPIs) and unit downtime calculations, providing a holistic overview of the factory's operational health.

Ultech Engineering, as the authorized system integrator and partner of Siemens Digital Industries, took center stage at OGA 2023 to demonstrate the prowess of Siemens Industrial Edge. The live demo provided a tangible experience of how this cutting-edge solution seamlessly integrates into industrial environments. The demonstration focused on illustrating the intricate flow of data within the Siemens Industrial Edge ecosystem. Starting from the In-Factory IE Devices (IED), the data was processed locally before being transmitted to Programmable Logic Controllers (PLCs). This decentralized approach ensures minimal latency and real-time data analysis.

The heart of the demonstration lay in showcasing how the processed data is then fed into the IE Management (IEM) dashboard. This dashboard, akin to traditional SCADA systems, serves as a centralized hub where managers can gain valuable insights into various aspects of factory performance, efficiency, and costs. What sets Siemens IE apart is its flexibility, allowing this comprehensive dashboard to be displayed on any screen, including mobile devices. This emphasis on accessibility reflects the adaptability of Siemens Industrial Edge in catering to the evolving needs of the industry, bringing Industry 4.0 concepts to life. The Ultech Engineering demo at OGA 2023 provided a tangible glimpse into the future of smart industry solutions powered by Siemens Industrial Edge.

In conclusion, Siemens Industrial Edge represents a pivotal shift in industrial technology, bringing the power of edge computing to factory management. By seamlessly integrating IT into the shop floor, Siemens IE empowers decision-makers with real-time insights and comprehensive analytics, setting the stage for a more efficient, cost-effective, and smarter industrial future. As the industry continues to embrace the benefits of edge computing, Siemens remains at the forefront, driving innovation and redefining the industrial landscape.

Siemens Digital Twin is designed to create a virtual representation of a physical product or system throughout its entire lifecycle, enabling simulation, analysis, and optimization of performance from design to maintenance.

Siemens Digital Xcelerator is a broader initiative that encompasses a portfolio of software solutions and services aimed at accelerating digital transformation in product design, engineering, and manufacturing processes. It focuses on enhancing collaboration, streamlining workflows, and accelerating innovation.

Siemens Digital Xcelerator primarily focuses on accelerating digital transformation in product development processes, emphasizing collaboration and innovation. Siemens Industrial Edge, on the other hand, is an edge computing platform specifically designed for the industrial sector, providing real-time processing and analytics capabilities at the edge of the network.

Siemens Industrial Edge brings edge computing capabilities to the shop floor, allowing for real-time processing of data closer to the source. It is tailored to enhance efficiency, performance, and decision-making in industrial settings by providing scalable, reliable, and user-friendly solutions.

Yes, these Siemens solutions can complement each other within a comprehensive digitalization strategy. Siemens Digital Twin can provide a virtual representation for simulation, Digital Xcelerator can enhance collaboration and innovation in product development, while Industrial Edge brings real-time processing to the shop floor, creating a holistic approach to digital transformation in industrial processes.