In a world increasingly connected by technology, have you ever wondered how SCADA & HMI systems play a silent yet pivotal role in shaping our industries and daily lives? Moving into the next segment from the first part, we now focus on HMI and SCADA, featuring our principal brands like Siemens, Mitsubishi Electric, and Allen-Bradley. These modern industrial automation technologies are the invisible architects behind the scenes, orchestrating a symphony of operations in sectors as diverse as marine, oil and gas, and general industry.

Early SCADA systems had difficulty connecting to other systems and communicating with remote terminal units (RTU) over wide area networks (WAN). The first-generation SCADA redundancy system has included having two mainframe systems - a main one and a backup - connected at the bus level. Moreover, the communication protocol was created by proprietary RTU suppliers.

During the second generation, SCADA systems were able to connect multiple stations through the use of LAN (Local Area Network) technology. This allowed for the real-time sharing of information, enhancing communication and information exchange within the SCADA network. Some of these stations managed communication for field devices, while others served as interfaces for operators. This improved connectivity enhanced processing power for SCADA systems used by utilities.

Third-generation SCADA systems embraced Wide Area Network (WAN) and Internet Protocols (IP), enabling the segregation of communication and monitoring functions. This separation improves system efficiency and reliability. Moreover, distributed processing divides tasks across the network, ensuring the system's continuous operation in the face of disasters or failures at specific locations or components.

PC-based SCADA is preferred in the oil and gas industry due to its cost-effectiveness and widespread use in both field operations and offices. Establishing a SCADA network through PCs ensures data is easily accessible across the company's operations. The advancements in PC technology have also spurred innovations in SCADA, empowering field operators to optimize their work efficiently. The versatility of PCs in SCADA is evident in their ability to provide interfaces for plant monitoring and facilitate data for informed decision-making within field operations.

All in all, PC-based SCADA stands out in development, offering cost efficiencies in design, maintenance, and development. PC-based development had less complexity and was compatible with the most sophisticated SCADA systems on the market. In the later segment, we will showcase PC-based SCADA products from our esteemed partners like Siemens, Mitsubishi Electric, and Rockwell Automation.

HMI acts as a critical link between industrial control systems and operators. It facilitates tasks like set point configuration and control algorithm adjustments, providing operators with real-time process status. In emergencies, HMI allows manual control. It integrates with SCADA, relying on its central monitoring station for higher-level control functions. The HMI interface's design, often using technologies like Visual Basic (VB) programming language and features such as Component Object Model (COM) and OLE for Process Control (OPC), aims to enhance productivity, increase uptime, and ensure constant product quality.

HMI and SCADA operate collaboratively, with HMI managing local control tasks and SCADA overseeing broader functions. The coordination ensures effective information exchange, contributing to enhanced control and monitoring of industrial processes. The combination of HMI and SCADA optimizes efficiency and safety in industrial operations.

Siemens HMIs are widely adopted in manufacturing and the energy sector, valued for their integration capabilities and versatility. Siemens HMIs can integrate with SIMATIC programmable logic controllers (PLCs) to provide efficient automation solutions. Siemens offers the Totally Integrated Automation (TIA) Portal software to enable comprehensive engineering and seamless integration of various automation components. The following showcases the SIMATIC HMI, categorized into Basic Panel, Comfort Panel, and Unified Comfort Panel.

Basic Panel: SIMATIC Basic Panels 2nd Generation offer cost-effective solutions for simple visualization tasks at the machine level. It prioritizes fast and intuitive operation while maintaining an attractive price-performance ratio.

Comfort Panel: SIMATIC HMI Comfort Panels are high-end operator panels with extensive functionality. Available in stationary and mobile options, they are tailored for high-performance visualization tasks on the machine level, ensuring maximum convenience through advanced features and integrated interfaces.

Unified Comfort Panel: SIMATIC HMI Unified Comfort Panel is part of the SIMATIC WinCC Unified system. Ranging from 7 to 22 inches, these high-end devices feature multitouch technology, vibrant colors, and high contrasts for enhanced user experience.

Utilizing SIMATIC WinCC Unified, they present new capabilities and features for devices in different size ranges. This encompasses the ability to extend functionality through apps, allowing users to run extra programs alongside standard device operations, all made possible by the integration of Siemens Industrial Edge.

Siemens offers a comprehensive range of SCADA solutions catering to diverse application scales. From the latest and advanced SIMATIC WinCC Unified system to the versatile SIMATIC WinCC v7/v8, and the professional-level SIMATIC WinCC Professional. Siemens ensures a tailored approach for different industrial needs.

SIMATIC WinCC Unified: Siemens' latest SCADA system is SIMATIC WinCC Unified. It provides advanced visualization and control capabilities while seamlessly integrating with SIMATIC controllers. WinCC Unified can be employed as an app for the Industrial Edge infrastructure and supports the use of SIMATIC S7-1500 controllers for visualization.

SIMATIC WinCC v7 / v8: SIMATIC WinCC v7/v8 is a rather earlier version of the WinCC SCADA system, providing complete functionality for process visualization tasks. These systems are flexible, supporting single-user systems to distributed multi-user systems with redundant servers. The system allows for easy scalability of quantity structure and functionality, including web solutions and redundant setups for maximum availability. The WinCC V7 IoT Gateway facilitates Industry 4.0 integration, providing transparency for machine and process data.

SIMATIC WinCC Professional: SIMATIC WinCC Professional is an advanced SCADA system with professional-level features that is integrated into the TIA Portal. It optimizes processes, enhances transparency, and supports process optimization for improved efficiency and cost-effectiveness. WinCC Professional is scalable, accommodating single-user systems to distributed multi-user systems and web-based solutions. Customized extensions are available through WinCC options and add-ons for industry-specific and technological solutions.

Mitsubishi Electric HMIs are a top choice in automotive and general manufacturing, seamlessly integrating with Mitsubishi Electric PLCs for specialized solutions and reliable performance. Mitsubishi Electric's HMI is the GOT Simple Series and GOT 2000 Series. The GOT Simple Series provides a simple and cost-effective HMI solution for basic tasks, while the GOT 2000 Series offers advanced features and capabilities for more complex industrial automation applications. Both series are programmed with GT Designer 3.

GOT Simple Series: Mitsubishi Electric's GOT Simple series is tailored for straightforward automation needs in small to medium-sized applications. It offers a cost-effective solution for entry-level automation needs, focusing on basic monitoring and control functions. The GS2107 (7" screen) and GS2110 (10" screen) models within this series offer flexibility with Ethernet, RS232, and RS422 options. The Ethernet feature enables convenient PC access for programming and monitoring.

GOT 2000 Series: The Mitsubishi Electric GOT2000 series serves a wide range of applications, featuring multi-touch/gesture control and high-quality graphics. It offers screen sizes from 3.8" to 15". The models include GT27 for high-end applications, GT25 for optimal balance, GT23 for cost-sensitive applications, and GT21 for entry-level use. The GOT2000 facilitates easy connectivity for remote operation and direct data transmission to higher-level databases.

GENESIS64, Mitsubishi Electric's innovative SCADA & HMI solutions harnesses the power of Microsoft .NET and OPC UA technologies. It seamlessly integrates data connectivity, aggregation, and visualization, offering a suite of products for a holistic industrial experience.

GENESIS64: GENESIS64 is a comprehensive SCADA & HMI solution that seamlessly integrates data connectivity, aggregation, and visualization across industries. GENESIS64 leverages advanced technologies like Microsoft .NET and OPC UA, offering a suite of products. This includes Workbench, GraphWorX™64, AlarmWorX™64, TrendWorX™64, EarthWorX™, MergeWorX™, ScheduleWorX™, and other components. The platform is designed to provide real-time information integration into a secure web-enabled dashboard.

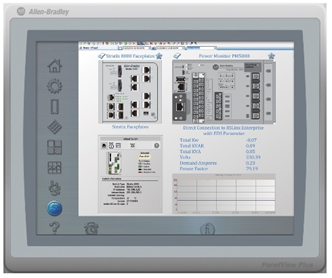

Allen-Bradley HMIs, from Rockwell Automation, are widely favoured in process industries such as oil and gas, chemical processing, and water treatment for their compatibility with Rockwell's process control solutions. In manufacturing, they are extensively used in discrete manufacturing processes due to their robust integration capabilities. The PanelView Plus 7 series, represent the latest technology from Rockwell Automation.

Panel View Plus 7: The PanelView Plus 7 monitor and control devices that are attached to ControlLogix 5570 and CompactLogix 5370 controllers on an EtherNet/IP network. The displays allow operators to observe the machine or process's operating state and interact with the control system using touchscreen input. The HMI functionality permits connection to 1 controller, up to 100 screens, and up to 500 alarms. The screen sizes range from 4 inches to 15 inches. The terminals support Ethernet communication with options for Device Level Ring (DLR), linear, and star network setups. Additionally, they feature a PDF viewer for accessing stored PDF files on the terminal.

FactoryTalk View by Rockwell Automation stands out as a powerful SCADA software suite renowned for its user-friendly visualization and control of manufacturing processes.

FactoryTalk View Site Edition: FactoryTalk View is a powerful SCADA software suite developed by Rockwell Automation. It is renowned for its user-friendly visualization and control of manufacturing processes. The key features included intuitive HMI design, real-time data collection, robust alarm management, trending and data logging, and enhanced security measures. In particular, the FactoryTalk View Site Edition (SE) provides enterprise-level capabilities, making it well-suited for large and complex manufacturing facilities.

The models vary in terms of features, processing power, memory, communication options, and I/O capabilities. Specific models cater to particular applications like motion control or temperature control, while others are geared toward general-purpose automation systems. Therefore, Ultech Engineering considers factors such as size, processing speed, performance, number of I/O, and communication options when recommending models as solutions for our clients.

In conclusion, SCADA & HMI systems play crucial roles in various industries. HMI serves as the bridge, translating machine language into a user-friendly interface, while SCADA acts as a vigilant overseer optimizing efficiency. Different brands such as Siemens, Mitsubishi Electric, and Allen-Bradley offer a range of SCADA & HMI solutions tailored to diverse application scales, from small to large. Looking forward, Ultech Engineering is unwavering in our commitment to infuse these leading-edge technologies into our solutions, guaranteeing a continuous journey of innovation.