November 22, 10 am - Ultech Engineering conducted an in-house training session for new employees working in various functions where the topics revolved around product training of PLC (Programmable Logic Controller), HMI (Human–Machine Interface) and SCADA (Supervisory Control and Data Acquisition). This article aims to introduce the product range under Ultech Engineering’s authorized brands like Siemens, Mitsubishi and Allen-Bradley within the scope of PLC, HMI and SCADA. This training was led by the Junior Automation and Control Engineers, Wong Voon Xing and Kelvin Tiong to improve the knowledge of the new staff and interns of Ultech Engineering.

At the beginning of the training, the engineers explained the concept of the automation pyramid. Based on the figure below, PLC, HMI & SCADA are mostly involved with the field level, control level, and supervisory level. These levels are also known as the operational technology (OT) level.

Field Level: Devices, sensors and actuators are deployed at the field level to process and collect signals. The field-level products are meant to inform users about data such as pressure, temperature etc. Users can then analyze the data to make decisions on the command for the output device.

Control Level: The control level can be industrial computers or any other controllers such as PLC to read signals from sensors. A Central Processing Unit (CPU), digital input/output (I/O), analog I/O, and communication modules are among the basic modules found in a typical PLC. Together, these parts give the PLC the ability to communicate with and manage a variety of industrial equipment.

Supervisory Level: At the supervisory level comes SCADA systems and HMI. At this level, users can perform controls such as diagnostics, on and off operations, emergency settings and more through the computers.

In the realm of industrial automation, the seamless interaction between Programmable Logic Controllers (PLC), Human-Machine Interfaces (HMI), and Supervisory Control and Data Acquisition (SCADA) systems plays a pivotal role. Some of the intricacies of how these components collaborate to enhance control, monitoring and efficiency were also shared in the training.

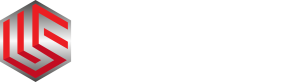

The Programmable Logic Controller (PLC) is a vital communication module that serves a crucial role in control and troubleshooting within SCADA systems. Its fundamental function includes processing and monitoring inputs sourced from sensors, actuators, or relays. These inputs are efficiently transmitted to the CPU, seamlessly integrating with a custom program. The PLC takes command of controlling output devices based on the determined inputs and outputs. Different types of PLCs, such as compact and modular PLCs, contribute to the flexibility and adaptability of these systems.

HMI, or Human-Machine Interface, serves as a user interface facilitating device control and data visualization. Commonly found in devices such as smartphones or tablets, HMIs enhance user comprehension. They act as controllers for devices, enabling seamless communication with PLCs. HMIs play a pivotal role in completing control and monitoring systems, serving as interfaces for connecting with various machines and devices. It's important to note that HMI operates on a local machine and, in comparison to SCADA, has limitations in data collection and recording capabilities.

SCADA, or Supervisory Control and Data Acquisition, is a system designed for efficient communication between various system components. Its purpose is to streamline processes, saving time and enhancing efficiency through rapid data processing. The architecture of SCADA involves key components, such as Programmable Logic Controllers (PLC) and Remote Terminal Units (RTU). PLCs function as microprocessor computers connected to local machines, while RTUs are utilized for remote operations. To illustrate, consider a scenario where SCADA notifies of a production error, facilitating quicker decision-making processes.

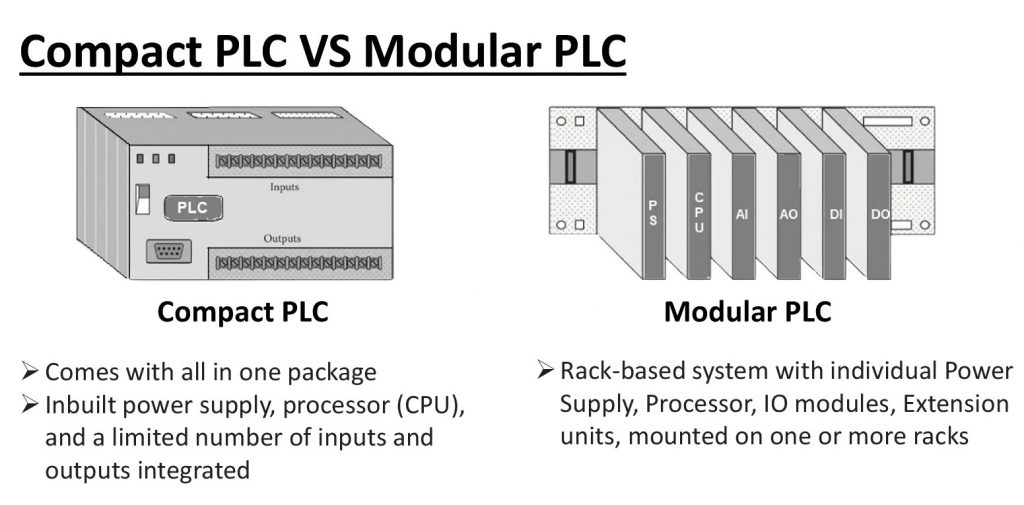

Siemens, headquartered in Munich, Germany, is a renowned multinational conglomerate and a leading PLC manufacturer known for its reliable and high-quality equipment. The Siemens PLC is known as SIMATIC PLC, where the word “SIMATIC” seamlessly combines 'Automatic' and 'Siemens.' The latest PLC is the SIMATIC S7 series, including S7-1500, S7-1200, S7-400, S7-300, S7-200, and LOGO!, embodies technological innovation.

The SIMATIC Series PLC three categories:

The SIMATIC S7 series is conveniently categorized into Micro PLC, Basic PLC, and Advanced PLC. This categorization aids users in identifying equivalent models when seeking upgrades, replacements, or adopting the latest technology. Aligning with Ultech’s commitment to cutting-edge solutions, our preference leans towards selecting S7-1200 (Micro PLC), S7-1500 (Basic PLC), and S7-400 (Advanced PLC).

S7-1200: A compact PLC, offering flexibility and cost-effectiveness. Limited I/O, with less memory and processing power. TIA Portal for programming.

S7-1500: High-performance PLC for complex automation tasks. Advanced functionality includes motion control, security, and safety features. Inbuilt display and keypad for basic configuration and diagnostics. TIA Portal for programming.

S7-400: High-performance PLC for demanding applications with extensive processing and communication needs. For complex automation tasks, offering various I/O modules, redundancy, and advanced diagnostics. Faster than the S7-300. Backplane rack–based parallel bus for swift communication between CPU & its modules. Step7 V5 for programming.

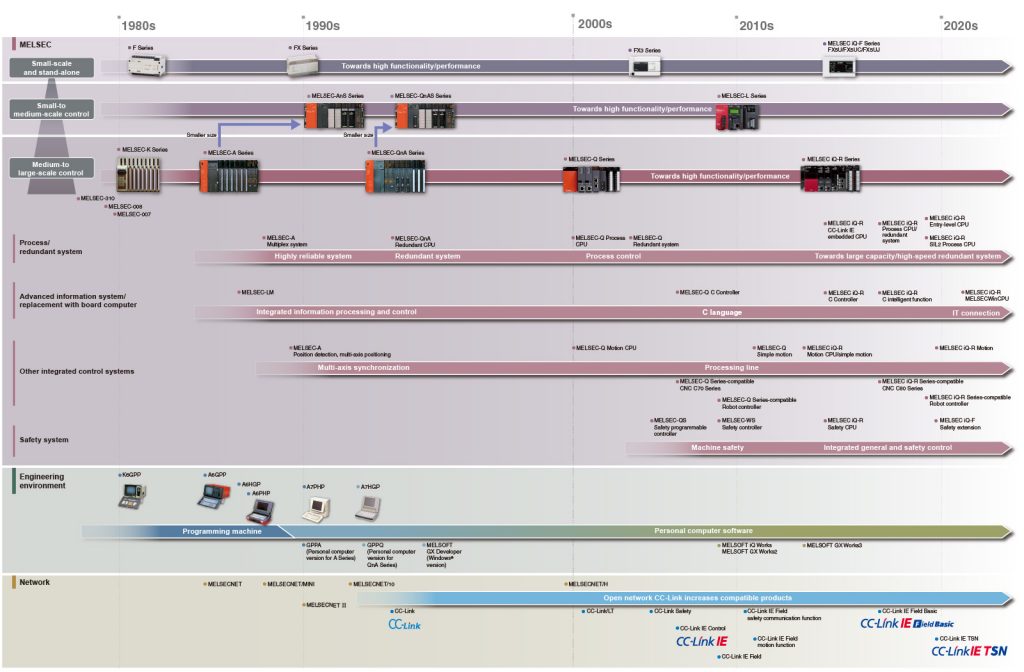

Mitsubishi Electric is well known throughout the world for producing automation solutions. Mitsubishi Electric's renowned PLC series is known as MELSEC. In addition to MELSEC, the FX Series is another PLC family that has evolved from the MELSEC series. In this section, we'll introduce PLC series that are in line with Ultech Engineering's commitment of ensuring continuous integration of the latest technology.

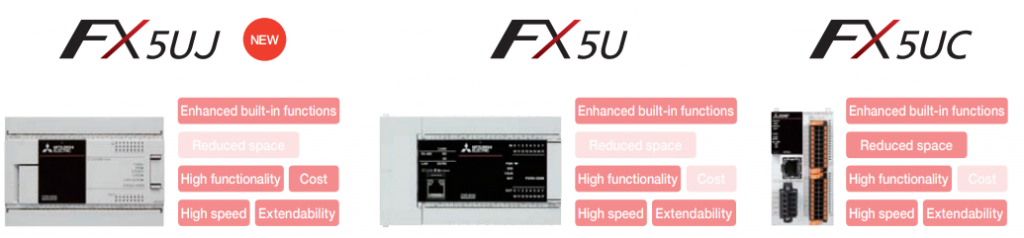

The MELSEC iQ-F Series represents the latest evolution of Mitsubishi's MELSEC-F Series, offering a compact PLC solution. The main design goals are outstanding performance, superior drive control, and user-centric programming. Under the MELSEC iQ-F Series, the models are FX5UJ, FX5U & FX5UC. The FX5 Series has enhanced built-in functions, which is an upgrade from the FX3 Series. In addition, the FX5 series retains its features of high functionality, high speed, and expandability. The figure below differentiates the functionality between the models. FX5UJ appears larger and more expensive, while FX5U, although also bigger, is comparatively less costly than FX5UJ. As a cost-effective and compact choice, FX5UC is often the preferred model.

The MELSEC-L Series is a baseless type PLC, a compact modular controller suitable for mid-size control applications. It doesn't require a base/rack, saving space. The CPU has built-in features, and customization is possible by adding modules only when needed. Additionally, the system allows flexibility in the number of slots for base units, potentially reducing costs by eliminating the need for expansion base units.

The MELSEC iQ-R Series stands out as a modular PLC, featuring a Modular Control System for customizable configurations. Its functionality extends to ensuring uninterrupted operation through Redundant System Architecture, enhancing system reliability. Furthermore, the series emphasizes cost-effectiveness by incorporating Redundant Power Supplies for continuous functionality, even in the face of power fluctuations or failures. This versatile and cost-effective solution is suitable for applications of various scales within industrial automation.

Rockwell Automation currently owns the Allen-Bradley brand. Allen-Bradley, a well-known brand in the field of factory automation equipment, offers a range of products, including PLCs, HMIs, and other automation solutions. As an authorized brand partner of Allen-Bradley, Ultech Engineering is well-equipped to introduce and provide expertise on various PLC series, including Micrologix, ControlLogix, and CompactLogix, ensuring comprehensive solutions for our clients.

MicroLogix1500: Designed for small, low-cost system that is ideal for use in standalone applications. Uses straightforward programming like RSLogix 500 software.

CompactLogix5370: Mid-range system that is designed for use in applications that require more processing power than the MicroLogix. Programmed using a modern, comprehensive environment like Studio 5000 Logix Designer software.

ControlLogix5000: An advanced Controller that is used for more complex and bigger systems. More expensive than a CompactLogix controller. Studio 5000 for programming.

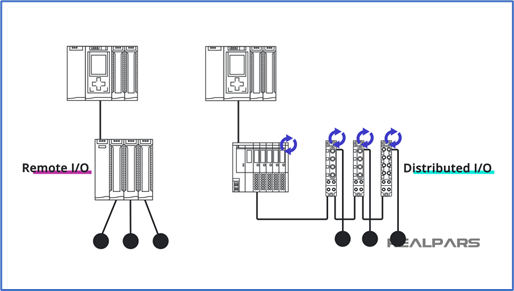

Remote I/O, also known as distributed I/O, is common in industrial and process automation with devices like DCS, PLCs, and PCs. It utilizes transmission technology for signal exchange. Remote I/O generally requires PLC to operate. The PLC processes inputs and outputs, as well as facilitating data exchange with the I/O sections of the PLC device. Even though remote I/O can reduce wiring, users need to take into account the time cost and material cost of implementing I/O modules depending on the application scale.

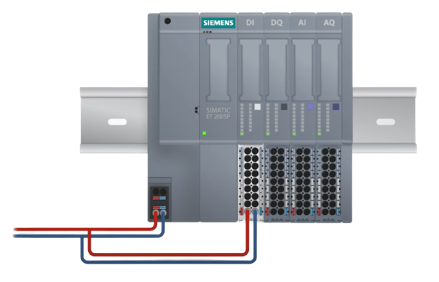

Latest I/O invention by Siemens is their distributed I/O, the SIMATIC S7-ET200SP. The ET200SP, a compact distributed I/O system compatible with other SIMATIC S7 PLCs, offers high flexibility, performance, and fail-safe peripheral modules. It utilizes the TIA Portal for programming. The ET200SP, belonging to the S7-1500 series with hot-swappable controllers, is smaller, features a different mounting system on cap-rail, and is encouraged for integration by Ultech Engineering.

Mitsubishi's MELSEC series that incorporate remote I/O capabilities are the MELSEC iQ-R Series and the MELSEC iQ- F Series. Additionally, Mitsubishi Electric often utilizes CC-Link as a communication protocol for its remote I/O modules. CC-Link is an industrial network protocol enabling seamless communication between PLCs, remote I/O modules, and other automation components, optimizing data exchange in industrial automation.

The Allen-Bradley remote I/O system allows for seamless integration, enabling users to expand and adapt their control systems to meet specific application requirements. Under Allen Bradley, Ultech Engineering introduces Point I/O Modules and Flex I/O Modules. Both Point I/O Modules and Flex I/O Modules are modular distributed I/O systems specifically designed for use in cabinets and tailored for distributed I/O applications.

Point I/O Modules: Easier to install, customize, and configure than Flex I/O. Drawback is bulky cables and difficult to fit into tight spaces.

Flex I/O Modules: More practical bus extension cable for installation flexibility. Greater terminals per point for improved efficiency. Suited for tight spaces compared to Point I/O.

In this section focusing on I/O modules, we showcase DEIF's Remote I/O, primarily recognized for its association with genset automation. Although DEIF's I/O modules excel in this specialized domain, it's essential to highlight that PLCs extend their application to a wider range of industrial scenarios. As an authorized partner of DEIF, Ultech Engineering ensures expertise and integration capabilities for DEIF's specialized Remote I/O modules, including CIO 116, CIO 208, and CIO 308, within our past projects.

CIO 116: External I/O module that offers an additional 16 digital inputs and outputs for DEIF systems

CIO 208: External I/O module that offers an additional 8 relay outputs for DEIF systems

CIO 308: External I/O module that has an additional 8 multi-functional inputs for the DEIF system

In conclusion, the in-house training serves as a valuable resource for beginners, providing insights into the diverse products and solutions offered by Ultech Engineering. While the training extensively covered PLCs, it also delved into HMI and SCADA, which will be shared in forthcoming articles. This particular article navigates the distinctions among PLCs based on application scale and highlights the latest technological advancements from our esteemed partners, such as Siemens, Mitsubishi Electric, Allen-Bradley, DEIF, and more. Looking ahead, Ultech Engineering remains committed to integrating these cutting-edge technologies into our solutions, ensuring a continuous trajectory of innovation. Ensure you don't miss out on valuable training opportunities in 2024, including specialized training sessions like Free DEIF Genset Controller Training and our Ex-Proof training and assessment, providing comprehensive insights into automation beyond PLCs.